ANDREAS MAIER GmbH & Co. KG

Products

WE GENERATE EXCITEMENT.

Precision tools & clamping technology

Hand held tools

HAND TOOLS

|

hand tools

Andreas Maier GmbH & Co. KG (AMF)

Hand held tools, mechanically

1. Quality from AMF There are very good reasons why a discriminating user should choose the best quality screwdriving tools: > rigorous quality control ensures uniform standards > seen as a whole, more economical, because the unproductive time spent while tools are issued is reduced to the essential minimum > in sizes up to ca. 6 A/F, the torque that can be applied by hand may be higher than the test torque that is specified in the relevant standard, with the resualt that: the wrench deforms, but only breaks under very unfavourable conditions, a modest, but valuable contribution is made to safety in the workplace; > the true value of quality tools can only be seen in real, practical use 2. Material Highly alloyed chrome-vnadium steel > tested steel sections in verifiably uniform quality from trusted suppliers ensure low wear for a long working-life. 3. Manufacture > end faces machined > end face up to 10 mm jaw opening chamfered process-sure > inspection by sampling at all stages of production 4. Execution Hardness to DIN standards > the values of minimum torque specified for tightening screws up to grade 12.9 are achieved or exceeded. 5. Surface finish > blued (Version C) > nickel-plated (Version D)

Clamping devices

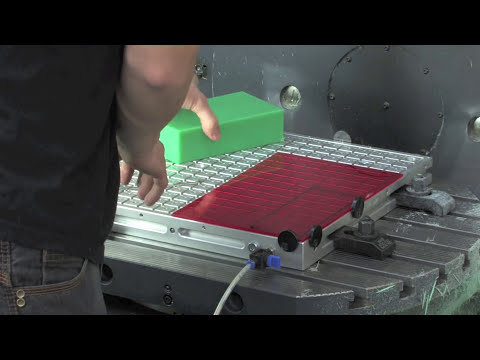

MAGNETIC CLAMPING TECHNOLOGY

|

Magnetic plate

Andreas Maier GmbH & Co. KG (AMF)

Magnetic clamping plates

The force of the magnetic field serves as the basis of this innovative technology, which clamps the workpiece reliably for machining on 5 sides. Surface quality and higher precision are the results of this unique combination of performance, safety and efficiency.

TOGGLE CLAMPS MANUAL AND PNEUMATIC

|

Chucking system

Andreas Maier GmbH & Co. KG (AMF)

Chucking systems

The features of our toggle clamps at a glance: > Ergonomic two-component handle > Safety clamping piece with finger protection > Retainer for clamping screws. > Stainless steel rivets > Removable rubber cap The most important facts ... Advantages of ?toggle? principle: > Large and quick opening. > Clearing the workpieces completely for unimpendend handling of work. > Large power transmission. Minimum operating effort giving maximum clamping force. > The clamps are self-arresting, they remain locked, resisting the force produced when machining components. Applications: A wide range of uses can be found for these AMF toggle clamps owing to their favourable power to movement ratio, and their easy action. These versatile clamps can be used in the metal working industry when drilling, welding, bending, grinding, testing and fitting, as well as in the wood and plastic industry in glueing, drilling, cutting and milling jigs.

ZERO-POINT - THE ZERO-POINT CLAMPING SYSTEM

|

Chucking system

Andreas Maier GmbH & Co. KG (AMF)

Chucking systems

"ZERO-POINT? CLAMPING SYSTEM

The AMF "ZERO-POINT-SYSTEM" with its innovative technology ensures perfect clamping. The highly precise clamping modules have high draw-in, locking and holding force and are suited for the widest range of applications. Progress that pays off

BLOCK-CLAMPING SYSTEMS

|

Clamping Systems

Andreas Maier GmbH & Co. KG (AMF)

Chucking systems

The simple solution for difficult tasks

Simple, fast, variable

Block clamping technology from AMF

- Fast clamping and releasing of the workpiece with just 1 screw

- Closed design prevents dirt from penetrating the clamping unit

- Inexpensive removal thanks to standardised intermediate elements

- Small space requirement, low weight

- Max. clamping force: up to 45 kN with system 7110

- Also groove dimensions 22 ? 36 mm, clamping height approx. 4000 mm possible with system 7100

SINGLE AND MULTIPLE CLAMPING SYSTEMS

|

Chucking system

Andreas Maier GmbH & Co. KG (AMF)

Chucking systems

Ideal for smaller components. Precision vices and clamps for reliable clamping ? even of complex external contours. The multiple clamping systems also achieve enormous time savings, which also permit clamping of multiple and different workpieces at the same time.

STANDARD CLAMPING ELEMENTS

|

Standard fixture part and clamping device

Andreas Maier GmbH & Co. KG (AMF)

Standard fixture parts and clamping devices

Unique versatility distinguishes the extensive product range, which offers the optimum clamping element for any type of application. At the same time, the individual products meet the highest demands for quality and innovation. This results in clamping solutions that optimise processes and are convincing in practice.

HYDRAULIC CLAMPING SYSTEMS

|

Clamping device, hydraulic

Andreas Maier GmbH & Co. KG (AMF)

Clamping devices, hydraulic

The principle of hydraulic clamping technology and its consistent further development is the basis for an extensive product range that impresses users with its quality and inspires with its versatility. Practical day-to-day needs and solutions to them are the benchmark and driving force here.

VACUUM CLAMPING TECHNOLOGY

|

Vacuum fixing plate

Andreas Maier GmbH & Co. KG (AMF)

Vacuum fixing plates

Each workpiece is fastened to the clamping plate by a vacuum so that it can be machined from all sides without any damage. Particularly in the timber, plastic and NE metal industry flexible vacuum clamping systems contribute towards the increase of economic efficiency and productivity.

MODULAR FIXTURE SYSTEM

|

Modular fixture system

Andreas Maier GmbH & Co. KG (AMF)

Other clamping devices

Flexible clamping technology belongs to flexible production technology.

You need modern clamping technology to optimally take advantage of the cost and competitive advantages of today's NC machines and similar systems. It contributes 10% to 30% of the efficiency effect. A flexible fixture system is needed, not expensive, time-wasting device construction.

To this end, we offer you a CAD library layout and design. With the uncompromising combination and coordination of software ad the modular fixture system we offer you key benefits. You can implement the device construction in a faster, more efficient and more manageable manner.

Modular fixture system – the benefits

> Two standardised sizes suitable in practice.

> 100% use, since every hole can be used for positioning and clamping.

> Cost-effective through hardened fit, thread and surface.

> Easy handling design through situation-based clamping: mechanical and/or hydraulic.

> Efficient through "flexible" device construction: the machine utilization time is increased by means of reduced setup and idle-machine times.

> The standard dimensions of the pallets, angles and cubes are suitable for machine tables in accordance with DIN 55201.

Special sizes are available on request