Assfalg

Products

Assfalg GmbH

Magnetic clamping plates

Magnaslot

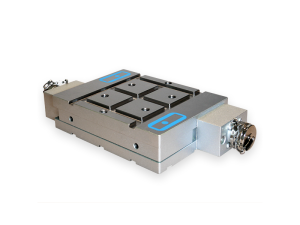

The patented (EPM) ElectroPermanent Magnetic chuck with solid steel top and squarepole technology is the perfect clamping solution for milling. Each pole is surrounded by opposite poles (chess pattern). Hence magnetic power flows in X- and Y- axis.

The current impulse for magnetizing and demagnetizing is very energy efficient. By using fixed and mobile pole extensions the roughness of unmachined or bent workpieces can be compensated. Also a distortion will be prevented.

Application:

The current impulse for magnetizing and demagnetizing is very energy efficient. By using fixed and mobile pole extensions the roughness of unmachined or bent workpieces can be compensated. Also a distortion will be prevented.

Application:

- Clamping of small and big workpieces for milling

- Clamping without vibration and without distortion

- Process accuracy with plane parallelism 0.02/1000 mm and better

- All-around 5 side machining and distortion free clamping is possible in one clamp by means of pole extensions

- Set-up time is reduced to a minimum, hence an increase of productivity

- Less vibrations for longer tool life and better process accuracy

- Patented solid top resists best to hot chips and coolance and cares also for heat dissipation O

Doublemag | Triplemag

|

Magnetic Clamping Elements

Assfalg GmbH

Magnetic clamping plates

52186, 51991, 57086

The Doublemag are small Magnaslots, but magnetized on top (to hold the workpiece) and on bottom (to hold itself on the machine table). They are very handisome and flexible in use.

They can be combined in multiple number to a large magnetic table to clamp economically large workpieces. The Triplemag are same as Doublemag, but have additional and separately switched magnets on bottom side, enabling a wanted position on the machine table or the wall before clamping the job. These magnets are manufactured as double row (DM502 or TM508) or single row (TM505).

Application:

They can be combined in multiple number to a large magnetic table to clamp economically large workpieces. The Triplemag are same as Doublemag, but have additional and separately switched magnets on bottom side, enabling a wanted position on the machine table or the wall before clamping the job. These magnets are manufactured as double row (DM502 or TM508) or single row (TM505).

Application:

- Clamping big or bulky workpieces for milling

- Clamping for edge cutting or deburring

- For simple and fast fixing of workpieces

- Also usable with fixed and movable pole extensions for uneven surfaces

- Drastic reduction of set-up times

- 5-side machining with simple and fast positioning and clamping

- Less stress, less vibrations, less torsions for better machining

- Flexible combination of multiple magnets to machine large or bulky workpieces

- Better accuracy-plane-parallelism 0,01/1000mm is reachable

- The advantage of fixed and mobile pole extensions for balancing uneven, bent, large workpieces

- Pole size 50 × 50 mm

- Adhesive force up to 350 kg per pole

- Full clamping force will only be achieve if the supporting table is ferromagnetic and at least 15 mm thick

- Penetration depth of the magnetic field up to 12 mm

- Patented solid top resists best to hot chips and coolance and cares also for heat dissipation

EPFlux

|

Magnetic Chuck

Assfalg GmbH

Magnetic clamping plates

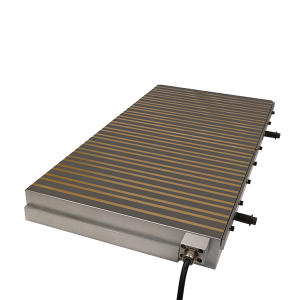

The EPFlux magnetic chuck is highly suitable for grinding applications of all size of jobs ? also for high alloyed and hardened workpieces. There will be nearly no residual magnetism. EPM technology guarantees therefore best accuracy. There is no heating up of the job. Energy consumption is very low.

Features:

Features:

- Clamping force approx. 100 N/cm²

- Pole pitch 5 + 1,5 mm

- Incorporated cable 3 m

- For Controller EPM D50-100 with additional Flux-IC

Magnaslot-T

|

Magnetic Chuck

Assfalg GmbH

Magnetic clamping plates

The patented (EPM) ElectroPermanent Magnetic chuck with T-Slots in the solid steel top combine advantages of magnetic and mechanic clamping and positioning for milling. The additional T-slots need a higher Magnaslot and are manufactured only together with squarepoles 75.

Application:

Application:

- All-around 5 side machining in one clamp

- For clamping of small and big workpieces by milling processes and rough and fine precision machining -

- Clamping of magnetic and nonmagnetic workpieces

- A combination of multiple EPM chucks enables large workpiece machininges also for heat dissipation

MICROFINE

|

Permanent magnetic chuck

Assfalg GmbH

Magnetic clamping plates

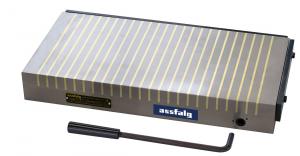

The Microfine is an extremely economical Permanent Magnetic Chuck which can be manually switched. It has a very flat magnetic field and is suitable for grinding and EDM. It is used for our Microsine.

Application:

Application:

- Universal use, especially for grinding and EDM, but also for finish milling

- Especially for small and thin, but also for thick workpieces if surface is clean and even

- Design with low height, but high adhesive force

- The contact surface can be machined up to 2mm and drilled up to max. 8 mm depth

- Liquid-tight

- Can be switched ON/OFF mechanically

- Work pieces can be clamped stress-free and fast

- 5-side processing, as only one side is magnetically clamped

- Adhesive force: 80 N/cm2 with pole pitch 1.5 + 0.5 mm

Permamax

|

Permanent magnetic chuck

Assfalg GmbH

Magnetic clamping plates

The Permamax is an extremely strong Permanent Magnetic Chuck - manually switched ON/OFF. It can be used universally for small and large, thin and thick workpieces on machine tools - especially for milling.

Application:

Application:

- Universal use, especially for milling of small and big workpieces (>30 × 15 × 6 mm)

- For thin, ferromagnetic workpieces from 0.8 mm thickness, as well as for thick workpieces

- Liquid tight

- Surface can be machined down by 2mm and partially drilled up to 8mm

- Switched ON/OFF mechanically

- Workpieces can be clamped stress-free and fast

- 5-side processing, as only one side is magnetically clamped

- High power and flat magnetic field (max. 10mm penetration into workpiece)

- Adhesive force: up to 140 N/cm2 with pole pitch 12 + 3 mm (highest power is concentrated within 20 mm from edges)

SINETABLE Microsine

|

Permanent Magnetic Sinetables

Assfalg GmbH

Magnetic clamping plates

Permanent Magnetic Chucks Magnet Sinetables are very helpful for angle works on grinding or milling machines, particularly in mould shops. The standard Microsine has the swivel axis in length and is equipped with Microfine. There are also Microsine sinetables with swivel axis in width, or in length and width. Any chuck can be taken in place of Microfine.

Application:

Application:

- Universal use, particularly for finishing operations

- For dry and wet machining

- Liquid-tight

- The standard Microsine is equipped with Microfine Magnetic Chuck

- The magnetic field is flat and the flux penetration in the workpiece is little

- The Microfine surface can be machined down by 2mm and partially drilled up to 8mm

- Workpieces can be fastly clamped with wanted inclination, stress-free

- Tilting angle is precisely set by sinustable and gauge blocks

- 5-side machining as only one side is clamped magnetically

- Adhesive force: 80 N/cm2 with pole pitch 1.5 + 0.5 mm - Swifel range 0 ? 45° (on request 0 - 60°)

- Surface hardened