BAUBLIES GROUP

Products

Non-cutting surface treatment and thread production

Ball burnishing tool

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

| up to 3500 rpm | |

| up to 500 rpm | |

| up to 0.02 mm | |

| 2–3 sec. | |

| emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life | |

| 5–20 revolutions | |

| surface roughness (Rz) up to 10 μm | |

| up to 45 HRC |

Tailor made tools for smoothening and work hardening of spherical surfaces. The tool contains conically arranged rollers. It is positioned to the workpiece under a defined setting-angle. Both workpiece and tool must rotate. During this process the spherical surface is burnished ?line by line?.

ADVANTAGES

- Useable on lathe machines with driven tools

- Very short machining time

- Slim design

- Fast return of investment

- Low machining forces

Einrollenwerkzeug, modulares System

|

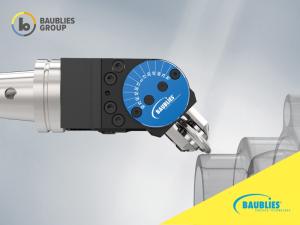

Roller burnishing tool

Baublies AG

Roller burnishing tools

| cylindrical shafts also against shoulder (1 roll in use at a time) | |

| from 15mm | |

| up to 200 m/min | |

| up to 1 mm/U | |

| up to 1.2 mm | |

| up to 0.02 mm | |

| emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life | |

| surface roughness up to 15 μm | |

| 45 HRC |

The modular single-roller tool system for lathe machines is an innovative solution for virtually all roller burnishing and roller compression tasks. A basic element is used to mount the interchangeable system components or rolling units. As a result, the tool can be converted in an extremely short time. This enables special machining tasks to be carried out quickly.

Expanding tool

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

| form closed connection of seat rings into valve housings | |

| as required | |

| as required | |

| up to 70 m/min | |

| up to 0.5 mm/rev | |

| emulsion or oil | |

| The seat ring is held by the tool so that automatic loading can take place before machining. |

Useable to connect valve seat rings into valve housings. The connection is form closed.

ADVANTAGES

- Automatic processing is possible

- The valve seat ring is fixed, guided and positioned by the tool

- Diameter range from DN 15 to DN 400 available

External roller burnishing tool PICCOLINO

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

| shaft against collar | |

| 1.0–7.9 mm | |

| −0.2 up to +0.1 mm | |

| 40 mm | |

| cylindrical shank Ø 6–22 mm Morse taper 1 to 3 | |

| up to 0.01 mm | |

| up to 0.04 mm | |

| clockwise (M3) | |

| always in rapid traverse (G0) | |

| emulsion or oil; filtration of the lubricant (<40 μm) canimprove the surface quality and the tool life | |

| surface roughness (Rz) up to 15 μm tolerance IT8 or better | |

| up to 45 HRC |

PICCOLINO external roller burnishing tools are a particularly compact design for use on machines with limited working space, such as multi-spindle and Swiss-type lathes or rotary transfer machines.

ADVANTAGES

- Very short machining time

- Surface finishes of the highest quality

- High productivity

- Workpiece is not subjected to lateral forces

- Both workpiece or tool can be driven

- Fast return of investment

- Slim design

- Usable on all common machines (no special machine required)

The best surface quality fast - that's a main characteristic of Baublies multi-roller burnishing tools. Depending on the roller burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

Internal taper roller burnishing tool

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

| internal taper | |

| from 3 mm | |

| as required | |

| up to 0.01 mm | |

| up to 4 mm | |

| emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life | |

| up to 50 m/min. referred to the biggest rolling diameter | |

| 0.1–0.3 mm/rev | |

| 5–20 revolutions | |

| surface roughness (Rz) up to 15 μm | |

| up to 45 HRC |

Tool for smoothening and strain hardening of internal tapers. Internal springs generate the required rolling force. The value of the rolling force is defined by the preload of the tool. The spring characteristics can be adapted to the requirements of the workpiece.

ADVANTAGES

- Short machining time

- Both workpiece or tool can be driven

- High productivity

- Low investment costs

- Simple replacement of wear parts

- Compact dimensions

Product designation Single-roller burnishing tool for recess grooves

|

Single-roller burnishing tool

Baublies AG

Roller burnishing tools

| recess grooves | |

| up to 120 m/min | |

| 0.05–0.15 mm/rev | |

| up to 0.01 mm | |

| up to 5 mm (adjustable preload) | |

| emulsion or oil; filtration of the lubricant (< 40 μm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 10 µm | |

| 45 HRC |

Single-roller burnishing tool for burnishing recess grooves.

ADVANTAGES

- Fast return of investment

- Optimized construction of rollers for machining application

- High productivity

- Slim design

- Simple replacement of wear parts

Roller burnishing tools for blind hole and through hole

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

Depending on the burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

ADVANTAGES

- Workpiece is not subjected to lateral forces

- Reduced machining times

- Harder surface layers

- Increase in fatigue strength

- Greater contact area due to plateau formation

- Higher surface resistance to wear and corrosion

- Increase in material fatigue limits

- Reduced sliding friction coefficients, constant dimensions and high fitting accuracy

- Environmental sustainability (as no grinding dust is produced)

- Suitable for use on all standard machine tools

Roller burnishing tools for external machining

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

Depending on the burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

ADVANTAGES

- Workpiece is not subjected to lateral forces

- Reduced machining times

- Harder surface layers

- Increase in fatigue strength

- Greater contact area due to plateau formation

- Higher surface resistance to wear and corrosion

- Increase in material fatigue limits

- Reduced sliding friction coefficients, constant dimensions and high fitting accuracy

- Environmental sustainability (as no grinding dust is produced)

- Suitable for use on all standard machine tools

Roller burnishing tools for through hole

|

Multi-roller burnishing tools

Baublies AG

Roller burnishing tools

Depending on the burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

ADVANTAGES

- Workpiece is not subjected to lateral forces

- Reduced machining times

- Harder surface layers

- Increase in fatigue strength

- Greater contact area due to plateau formation

- Higher surface resistance to wear and corrosion

- Increase in material fatigue limits

- Reduced sliding friction coefficients, constant dimensions and high fitting accuracy

- Environmental sustainability (as no grinding dust is produced)

- Suitable for use on all standard machine tools

Single-roller burnishing tool for internal-, external- and taper machining

|

Single-roller burnishing tool

Baublies AG

Roller burnishing tools

| internal-, external-, and taper machining | |

| square shank 25 mm | |

| from 35 mm | |

| up to 200 m/min | |

| 0.05 – 0.3 mm/rev | |

| up to 0.02 mm | |

| up to 0.5 mm | |

| emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life | |

| surface roughness up to (Rz) 15 μm | |

| up to 45 HRC |

This single roller burnishing tool is used for burnishing rotationally symmetrical internal and external diameters. It also can be used for taper machining.

Advantages

- Universally usable

- Easy to use

- Slim design

- Fast return of investment

Variable single-roller burnishing tool

|

Single-roller burnishing tool

Baublies AG

Roller burnishing tools

| shafts, contours, recess grooves, plane surfaces | |

| square shank 20/25/32/40 mm | |

| ±90 ° in 15 °-steps adjustable | |

| 2 mm | |

| up to 200 m/min | |

| 0.05 – 0.3 mm/rev | |

| up to 0.02 mm | |

| up to 1 mm | |

| emulsion or oil; filtration of the lubricant (< 40 μm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 15 μm | |

| up to 45 HRC |

Variable single-roller burnishing tool for smoothing and hardening internal and

external contours.

Variable single-roller burnishing tools are flexibly adjustable for various contours and can also be used in hard-to- reach places. The rolling unit can be swiveled by 180°.

ADVANTAGES

- Adjustable angle for various contours

- Optimal design of the rollers for profile machining

- Universally applicable due to compact design

Internal roller burnishing tool PICCOLINO

|

Multi-roller burnishing tool

BAUBLIES AG

Roller burnishing tools

| blind hole and through hole | |

| as required | |

| as required | |

| 4mm | |

| -0.1 to +0.1 mm | |

| from Ø 8 mm | |

| up to 0.02 mm | |

| up to 0.03 mm | |

| clockwise (M3) | |

| always in rapid traverse (G0) | |

| Emulsion or oil | |

| surface roughness (Rz) up to 12 µm tolerance IT8 or better | |

| up to 45 HRC |

PICCOLINO internal roller burnishing tools are a particularly compact design for use on machines with limited working space, such as multi-spindle and Swiss-Type lathes or rotary transfer machines.

ADVANTAGES:

- Very short machining time

- Surface finishes of the highest quality

- Easy to maintain

- High productivity

- Both workpiece or tool can rotate

- Fast return of investment

- Usable on all common machines (no special machine required)

The best surface quality fast - that's a main characteristic of Baublies multi-roller burnishing tools. Depending on the roller burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

TSW knurling tool

|

Form knurling tool

WAGNER TOOLING SYSTEMS BAUBLIES GMBH

Form knurling tools

The tangential WAGNER knurling tool TSW is the "knurling professional" among the WAGNER tools and is an economical version of the versatile and proven thread rolling tool.

With the TSW, knurls, parallel grooves, profiles and beads can be rolled up in a time-saving manner.

During machining - preferably on single and multi-spindle lathes - the workpiece must rotate; the tool itself is stationary.

Twist-free smoothing:

When grinding rotationally symmetrical workpieces, interfering twist structures very often occur.

This twist impairs the flow behaviour of the fluid to be sealed in the contact zone and leads to sealing problems, especially in the case of workpieces with a sealing function.

With a roll width of up to 43 mm, the TSW can be used to smooth such sealing seats without twisting.

will be. Roughness depths smaller than 1 µm can be achieved.

ADVANTAGES

- Cost-effective purchase price

- Simple operation

- Easy and fast roll change

- Simple diameter correction

- Sturdy tool body

- With a roll width of up to 43 mm, a working range of diameter 3 to 40 mm can be covered.

With the TSW, knurls, parallel grooves, profiles and beads can be rolled up in a time-saving manner.

Tangential rolling heads

|

Thread rolling tool

WAGNER TOOLING SYSTEM BAUBLIES GMBH

Thread rolling tools

With the Wagner tangential rolling tool, threads of the highest surface quality are produced with the shortest machining times.

The tangential rolling attachment is mounted with the adapter on the tool carrier, e.g. a turret disc.

It moves at a constant feed rate onto the rotating workpiece. The thread rolls are set in rotation by contact with the workpiece and form the thread as the tool carrier continues to feed. As soon as the thread rolls are centered on the workpiece, the rapid return is initiated and the workpiece is released.

Highest productivity can be achieved by using precise thread rolls with maximum service life. These are adapted in diameter, pitch and shape to the thread to be rolled.

Wagner tangential rolling tools are available in various sizes and are suitable for machining workpieces from Ø 2 - 72 mm.

Best roll results with fine threads are achieved by using our tool variant "F". For threads with very small pitches, it is important to keep the axial play of the thread rolls as low as possible. With the patented WAGNER axial clearance fine adjustment, the axial roller clearance can be minimised in 0.02 mm steps. Fine adjustment is available as an option.

Profile rollers for special applications such as rollers for lubrication grooves, knurling or smoothing are also available.

fields of application

- Cylindrical and conical threads, right- and left-hand threads as well as regular and fine threads

- Thread behind a collar

- Thread to close to a collar

- Very short threads

- Thread with workpiece end not free

- Thread with very short outlet

advantages

- Large working range

- Long service life due to large rollers and high rigidity of the tool body

- Particularly low maintenance

- The rolled threads are suitable for high loads due to their uninterrupted grain flow.

- Durable, wear-resistant and corrosion-resistant threads

- High flexibility due to numerous adapter variants for use on different machines, e.g. single-spindle and multi-spindle lathes as well as special machines

- Short processing time

Axial rolling heads HELIX

|

Thread rolling tool

WAGNER TOOLING SYSTEM BAUBLIES GMBH

Thread rolling tools

Our expert for thread rolling

- Very compact tool

- Above average thread roll diameters extend the tool life

- Front panel with large bore for large collar diameters

- Unrivalled large working range (nominal ø 10 mm to 22 mm) for e.g. long threads

- Sustainable: wear parts that can be replaced at low cost

- Coating for max. wear protection

- User-friendly due to easy handling and replaceable wear parts

- Locking with max. service life

- Stable mounting of the exchangeable shanks (for all common interfaces)

- Closing lever steplessly positionable

- Simple and precise fine adjustment due to stop on both sides

Tangential rolling head with stem

|

Thread rolling tool

WAGNER TOOLING SYSTEM BAUBLIES GMBH

Thread rolling tools

Only WAGNER offers tangential rolling tools with pre-assembled rollers. This makes it possible to roll threads directly to the collar or chuck. Naturally with the shortest processing times.

These tools are designed for use on all common lathes with a controlled feed movement.

advantages

- Problem solver for demanding workpiece geometries

- Simple operation

- Easy and fast roll change

- Simple diameter correction

- Sturdy tool body

- Short processing time

Axial rolling heads modular

|

Thread rolling tool

WAGNER TOOLING SYSTEM BAUBLIES GMBH

Thread rolling tools

Threads of the highest surface quality are produced in an unparalleled wide operating range with the use of the axially operated WAGNER® thread rolling head.

The large machining capacities of the individual rolling head types are made possible by the quick and easy replacement of the roller holders. These differ in the working range and the holder angle.

Other forming operations such as knurling, beading, rolling and smoothing can also be carried out. The heads are suitable for stationary or rotational use.

The axial head is closed by radial rotation of the closing handle or respectively by an automatic closing device. The opening mechanism of the head is triggered by the feed stop and the rollers release the workpiece.

APPLICATION AREAS

- right-hand and left-hand threads as well as standard and fine pitch threads, pipe threads, trapezoidal threads and special threads

- profile rollers available for special applications such as rollers for lubrication grooves, knurling or smoothing

- rotating and stationary designs for use on lathes, machining centres, Rotary transfer machines and special machines

- machining of long threads ? suitable for both small series and large batch sizes

ADVANTAGES

- Reduction of acquisition costs due to modular design

- Precision thread rolls of the highest quality

- Self-opening for non-contact return flow

- Machining of threads with different profile shapes, right- and left-handed with only possible with one head

- Highest productivity

- High flexibility on almost all machines due to commercially available holders

- Short processing times

With the Wagner axial rolling head, threads with various profile shapes can be produced in a short time.

COLIBRI Diamond burnishing tools for external machining

|

Diamond-burnishing swiss lathe

BAUBLIES AG

Roller finishing and deep rolling tools

| shafts and external contours | |

| square shank, left or right holfer, cylindrical shank | |

| up to 150 m/min | |

| 0.05 - 0.2 mm/rev | |

| up to 0.02 mm | |

| up to 1 mm | |

| emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 15 µm | |

PERFECT FINISH FOR SOPHISTICATED WORKPIECES.

Small, fine and in excellent Baublies quality: these are the new burnishing tools that we have developed especially for filigree applications. We have optimized our many years of knowhow in diamond burnishing for the machining of small precision parts and thin-walled workpieces in a compact form.

ADVANTAGES:

- Highest surface quality and hardening

- Universally applicable

- Simple to use

- Ideal for contour machining

- For hard machining and thin-walled workpieces

- Compact design available for machines with limited tool space

- Tolerance compensation through spring-loaded design

- Can be adapted to all materials by means of four spring elements (included in delivery)

- Changeable diamond insert

- Diamond inserts available in different lengths

- Diamond radii from 0.4 - 5 mm available

- Diamond indexed for multiple machining

- Re-grinding of the diamond is possible

- Cost-effective/low investment

Diamond burnishing tools from the COLIBRI series are always optimally suitable when the peak-to-valley height of filigree workpieces is to be minimized and at the same time the strength is to be increased.

Diamond burnishing for internal use of plane surfaces

|

Roller finishing and deep rolling tool

Baublies AG

Roller finishing and deep rolling tools

| Internal plane surfaces | |

| cylindrical shank from Ø 16 mm | |

| up to 50 m/min. referred to the biggest rolling diameter | |

| 0.05 mm/rev | |

| up to 0.01 mm | |

| up to 1 mm | |

| emulsion or oil; filtration of the lubricant (<40 μm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 8 μm | |

| up to 45 HRC |

Shape bound tool for smoothening and strain hardening of plane surfaces.

ADVANTAGES

- Simple to use

- Compact design available for machines with limited tool space

- Universally applicable

- Tolerance compensation through spring-loaded design

- Changeable diamond insert

- Cost-effective/?low investment

Diamond burnishing tool for holes and contours

|

Diamond burnishing tools

Baublies AG

Roller finishing and deep rolling tools

| internal holes and contours | |

| cylindrical shank Ø 20/25/32/40 mm with clamping surface | |

| up to 150 m/min | |

| 0.05–0.2 mm/rev | |

| up to 0.02 mm | |

| up to 1 mm | |

| emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 15 µm | |

Diamond burnishing tools for internal use are non-intrinsic tools for smoothening and work hardening of holes and contours.

ADVANTAGES

- Simple to use

- Compact design available for machines with limited tool space

- Can be adapted to all materials by means of four spring elements (included in delivery)

- Diamond radii from 0.4?5 mm available

- Diamond indexed for multiple machining

- Highest surface quality and hardening

- Universally applicable

- Ideal for contour machining

- For hard machining and thin-walled workpieces

- Tolerance compensation through spring-loaded design

- Changeable diamond insert

- Re-grinding of the diamond is possible

- Cost-effective/low investment

Diamond-burnishing tools: for highest precision

Diamond-burnishing tools expand the range of applications of roller burnishing technology, as even hardened materials up to approximately 60 HRC can be roller burnished.

In the process, a high-precision, micropolished diamond glides over the surface. As soon as the yield point of the material is exceeded, the profile peaks of the workpiece surface flow into the adjacent recesses in the µm range.

Compared to the machining by means of rollers, the contact area between the workpiece and the diamond is much smaller. Therefore, plastic cold working with a reduced influence of force can take place. Baublies diamond roller burnishing tools advance into hardness and diameter areas in which conventional roller burnishing tools cannot be used due to the workpiece characteristics or geometry. With diamond-burnishing tools, all contours - internally and externally - can be roller-burnished and deep-rolled.

Diamond burnishing tool für recessing

|

Diamond burnishing tools

Baublies AG

Roller finishing and deep rolling tools

| chamfers, recesses and flat surfaces | |

| square shank 12/16/20 mm, left hand or right hand | |

| up to 150m/min | |

| 0.05−0.1mm/rev | |

| emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 10 µm | |

Diamond burnishing tools are shaped tools for smoothing and work hardening of chamfers, recesses and flat surfaces.

ADVANTAGES

- Universally useable

- Suitable for hard machining and thin walled workpieces

- Slim design enables the application in small spaced machine tools

- Adjustable diamond insert (angle)

- Changeable diamond insert

Diamond-burnishing tools: for highest precision

Diamond-burnishing tools expand the range of applications of roller burnishing technology, as even hardened materials up to approximately 60 HRC can be roller burnished.

In the process, a high-precision, micropolished diamond glides over the surface. As soon as the yield point of the material is exceeded, the profile peaks of the workpiece surface flow into the adjacent recesses in the µm range.

Compared to the machining by means of rollers, the contact area between the workpiece and the diamond is much smaller. Therefore, plastic cold working with a reduced influence of force can take place. Baublies diamond roller burnishing tools advance into hardness and diameter areas in which conventional roller burnishing tools cannot be used due to the workpiece characteristics or geometry. With diamond-burnishing tools, all contours - internally and externally - can be roller-burnished and deep-rolled.

Variable (straight) diamond burnishing tool for shafts and contours

|

Diamond burnishing tools

Baublies AG

Roller finishing and deep rolling tools

| external shafts and contours | |

| square shank 20 × 32/25 × 32/32 × 32 | |

| 180° | |

| 36 × 5° | |

| up to 150 m/min | |

| 0.05–0.2 mm/rev | |

| up to 0.02 mm | |

| up to 1 mm | |

| emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 15 µm | |

Variable diamond burnishing tools for external use are non-intrinsic tools for smoothening and work hardening of shafts and contours. Due to the swiveling diamond these tools are very versatile.

ADVANTAGES

- Simple to use

- Compact design available for machines with limited tool space

- Can be adapted to all materials by means of four spring elements (included in delivery)

- Diamond radii from 0.4?5?mm available

- Diamond indexed for multiple machining

- Highest surface quality and hardening

- Universally applicable

- Ideal for contour machining

- For hard machining and thin-walled workpieces

- Tolerance compensation through spring-loaded design

- Changeable diamond insert

- Re-grinding of the diamond is possible

- Cost-effective/low investment

Diamond smoothing tools: for highest precision

Diamond smoothing tools extend the range of applications for smoothing and strengthening surfaces of hardened materials up to over 60 HRC.

A diamond glides over the surface to be smoothed. As soon as the yield point of the material is exceeded, the profile tips on the workpiece surface flow into the adjacent recesses in the µm range. Since the contact area between the workpiece and the diamond is smaller than in the case of machining by means of rollers, the plastic cold deformation can take place with less force.

Diamond smoothing tools are used in areas where single and multi-roll tools reach their limits due to material properties or the geometry of the workpiece. Diamond smoothing tools are available for both internal and external machining.

Variable diamond burnishing tool for holes and contours

|

Diamond burnishing tools

Baublies AG

Roller finishing and deep rolling tools

| internal holes and contours | |

| cylindrical shank Ø 20/22/25/32/40 mm | |

| 240° | |

| 48 × 5° | |

| up to 150 m/min | |

| 0.05–0.2 mm/rev | |

| up to 0.02 mm | |

| up to 1 mm | |

| emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 15 µm | |

Variable diamond burnishing tools for internal use are non-intrinsic tools for smoothening and work hardening of holes and contours. Due to the swiveling diamond these tools are very versatile.

ADVANTAGES

- Simple to use

- Compact design available for machines with limited tool space

- Can be adapted to all materials by means of four spring elements (included in delivery)

- Diamond radii from 0.4?5?mm available

- Diamond indexed for multiple machining

- Highest surface quality and hardening

- Universally applicable

- Ideal for contour machining

- For hard machining and thin-walled workpieces

- Tolerance compensation through spring-loaded design

- Changeable diamond insert

- Re-grinding of the diamond is possible

- Cost-effective/low investment

Diamond-burnishing tools: for highest precision

Diamond-burnishing tools expand the range of applications of roller burnishing technology, as even hardened materials up to approximately 60 HRC can be roller burnished.

In the process, a high-precision, micropolished diamond glides over the surface. As soon as the yield point of the material is exceeded, the profile peaks of the workpiece surface flow into the adjacent recesses in the µm range.

Compared to the machining by means of rollers, the contact area between the workpiece and the diamond is much smaller. Therefore, plastic cold working with a reduced influence of force can take place. Baublies diamond roller burnishing tools advance into hardness and diameter areas in which conventional roller burnishing tools cannot be used due to the workpiece characteristics or geometry. With diamond-burnishing tools, all contours - internally and externally - can be roller-burnished and deep-rolled.

Variable diamond burnishing tool for shafts and contours

|

Diamond burnishing tools

Baublies AG

Roller finishing and deep rolling tools

| external shafts and contours | |

| square shank 16/20/25 mm left or right hand | |

| 240° | |

| 48 × 5° | |

| up to 150 m/min | |

| 0.05–0.2 mm/rev | |

| up to 0.02 mm | |

| up to 1 mm | |

| emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life | |

| surface roughness (Rz) up to 15 µm | |

Variable diamond burnishing tools for external use are non-intrinsic tools for smoothening and work hardening of shafts and contours. Due to the swiveling diamond these tools are very versatile.

ADVANTAGES

- Simple to use

- Compact design available for machines with limited tool space

Can be adapted to all materials by means of four spring elements (included in delivery)

- Diamond radii from 0.4?5?mm available

- Diamond indexed for multiple machining

- Highest surface quality and hardening

- Universally applicable

- Ideal for contour machining

- For hard machining and thin-walled workpieces

- Tolerance compensation through spring-loaded design

- Changeable diamond insert

- Re-grinding of the diamond is possible

- Cost-effective/low investment

Diamond smoothing tools: for highest precision

Diamond smoothing tools extend the range of applications for smoothing and strengthening surfaces of hardened materials up to over 60 HRC.

A diamond glides over the surface to be smoothed. As soon as the yield point of the material is exceeded, the profile tips on the workpiece surface flow into the adjacent recesses in the µm range. Since the contact area between the workpiece and the diamond is smaller than in the case of machining by means of rollers, the plastic cold deformation can take place with less force.

Diamond smoothing tools are used in areas where single and multi-roll tools reach their limits due to material properties or the geometry of the workpiece. Diamond smoothing tools are available for both internal and external machining.

Loading ...