EuroBLECH 2018: TUBE&SHEET, the best united

EuroBLECH 2018 is the perfect occasion for BLM GROUP to emphasize their broad product portfolio. The presented slogan “TUBE&SHEET, the best united”, will focus on quality as well as the range of technological advances in tube and sheet processing the Group is able to offer. Therefore, not only tube but also a complete laser systems family dedicated to metal sheets

In EuroBLECH’s pavilion 12 at the booth A36/B36, BLM GROUP will present a selection of cutting-edge tube and sheet fabricating systems synchronized by proprietary and dedicated software applications. Visitors will experience how integrated technologies drive new levels of efficiencies to grow core business and new opportunities.

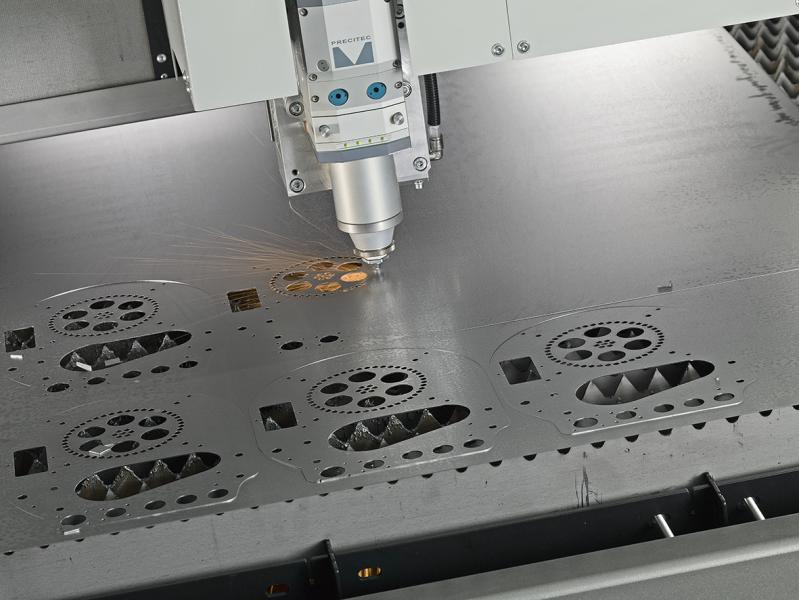

It is well known that the exposition’s main theme is sheet cutting systems. BLM GROUP has reputable experience and has a system family known for their excellent performances and flexibility, particularly in the combined tube-sheet version, which remains a pioneering solution in the global machine tool market.

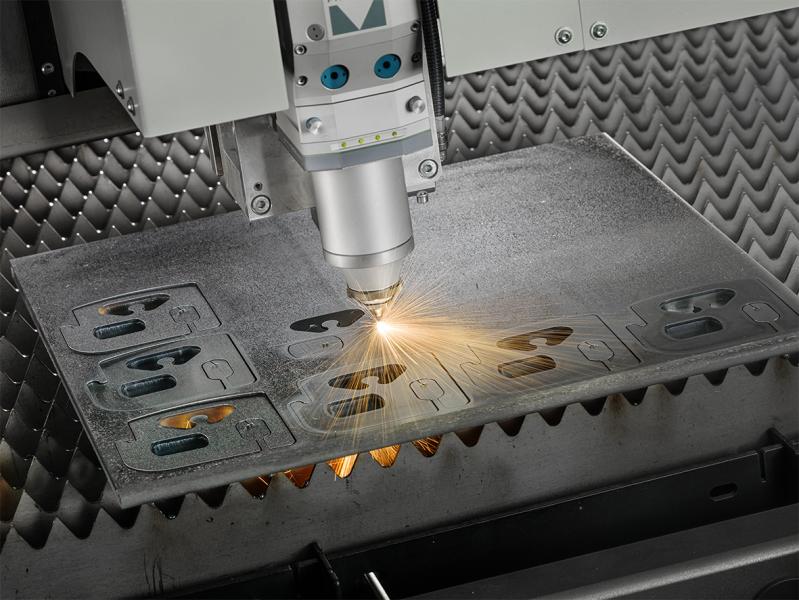

As we were saying, not only tube, and the LS5 system in view at the exposition effectively proves it. Complete automation with automatic loading and unloading, autofocus head, and automatic nozzle change. Modularity, a differentiated feature of this system family, is at the peak of development with the LS5. The system is configurable with transversal and longitudinal pallet change to handle different sheet metal formats. For expanded capability, it can also be integrated with an automatic tube manufacturing system.

LT-FREE, a 5 axes system for the processing of curved tubes and 3-dimensional deep-drawn components is another way of portraying the conjunction between sheet and tube. If the manufacturing of these details is not unusual for these kind of systems, the idea of utilizing two robots to support small pieces, and curved tubes during laser cut, makes this system particularly flexible and suitable for operations others can’t do.

LT-FREE executes entire programs in a single pass, without the need to abort and resume fabricating, as a result of the interpolation between the 5 axes head and the piece’s motion carried out by the robot, which ensures an extreme movement flexibility.

The different automatic loading and unloading possibilities, including complete bin picking detection, make this system particularly flexible and suitable to any type of manufacturing.

BLM GROUP cannot fail to display the Lasertube systems family, a name that became over time, synonymous with tube laser processing. As the newest member of the family, BLM GROUP shows EuroBLECH the highly advanced LT7 system.

The LT7, a jewel of modern technology, was researched and developed on the basis of 30 years of expertise in tube laser cutting. The handling of tubes is fast and efficient, yet careful and delicate not to damage the surfaces. The technologies in the Active functions offer simple solutions to otherwise very complex problems. The available software applications, starting from Artube CAD/CAM, assist the operator in all the stages of the programming and production processes and represent a key aspect of success of the entire Lasertube family.

All of this has played a part in the final result of a system that can still amaze in performance and continues to be extremely easy to use.

Last but not least the E-TURN bending system will be displayed to represent the tube bending world, where BLM GROUP is long-time leader. The E-TURN represents a much replicated, but never duplicated, achievement in metal tube-bending flexibility. The items B-RIGHT and B-TOOL ensure a tube is made to specification from the start of production, further supporting BLM GROUP’s leadership in this traditional sector of our production.

B-RIGHT and B-TOOL represent a practical example of technology advancement in tube manufacturing to which BLM GROUP committed significantly to over the past several years. The systems that contribute to the realization of a product, from laser-cutting to bending, communicate with each other to achieve an accurate, fully-processed part in the shortest amount of time, from production of the first part. The supervision of the production through the use of application software like Protube Enterprise, results in maximum efficiency and productivity.

Learn how to simplify complex laser cut parts with Artube, use VGP3D to plan and simulate bending jobs, and calculate time study estimates using other applications like Protube Enterprise within the BLMelements software suite. ProTube Enterprise, ArTube, and VGP3D software will be demonstrated at the BLM GROUP stand using practical examples to solve everyday manufacturing challenges.

BLM GROUP, not only tube.

BLM GROUP

BLM GROUP is a global partner for the entire tube fabrication industry with a worldwide presence and thousands of successful installations in a wide variety of industries.

- BLM SPA, based in Cantù (CO), specializes in the production of CNC tube-bending machines, end forming, wire bending equipment and related automation devices.

- ADIGE SPA based in Levico Terme (TN), manufactures systems for laser-cutting tubes and machines for saw cutting tubes, bars and sections. The range is augmented with wire brushing machines, measuring systems, washing systems and collectors.

- ADIGE-SYS SPA based in Levico Terme (TN) specializes in the production of "hybrid" laser-cutting systems for cutting both tubes and sheet metal, plus a line of large capacity laser tube cutting machines and related part handling.

Facebook: www.facebook.com/BLMGROUP

YouTube: www.youtube.com/BLMGROUPchannel

Linkedin: www.linkedin.com/company/blmgroup

Twitter: www.twitter.com/blmgroup

Italy

Italy