BLM GROUP

Products

Wire forming machines

Wire bending and forming machines

DH2010VGP

|

Wire bending and forming machine

BLM GROUP

Wire bending and forming machines

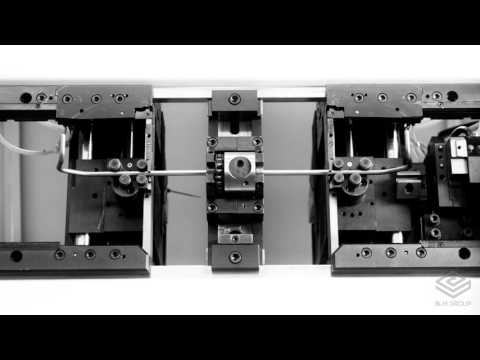

DH2010VGP is the new automatic, all-electric, double head wire CNC-bending machine with 3D graphical interactive programming software (VGP3D).

Equipped with two bidirectional bending heads (clockwise and counter-clockwise) with variable radius feature, DH2010VGP doubles productivity rates and bends in one cycle even complex wire and/or tube shapes both with coil feeding and straightened cut to length bar.

The machine offers the following advantages:

• Very high productivity rate thanks to double head simultaneous bending and to the advanced working cycle generated by the VGP3D

• Left/right bending with variable radius facility on the same head and with the same tooling

• Automatic unload of the finished parts

• Automatic coil feeding and/or straightened cut to length bar not requiring set-up times

• Part straightening with in-line device at constant speed

• The central clamping unit allows to bend more complex shapes such as closed parts, ends with eyelets, ends that reverse back to the inside of the closed parts, and to control possible flexions of the parts

• Ability to bend a "double" part (symmetrical or same) and cut them apart after the bending

• Deep and clean chamfering, burr-less, before the bending cycle

• Constant repeatability and accuracy

• Cheaply to run (power consumption reduced up to 50% compared to electro-hydraulic machines)

Programming is made through the BLM graphical interactive programming software VGP3D, with:

• Component feasibility check and generation of the most suitable working cycle (times and costs)

• Likely collision risks are highlighted and the most efficient avoidance route selected automatically

• by simply inputting the component bend coordinates, the complete bending program is graphically simulated.

Particularly suitable to work medium and long parts with many bends, symmetrical or asymmetrical or with closed frame structure, mainly used by the following industries: automotive, household appliances, in- and out-door furniture, shop displays and electrical heaters, as well as armoured electrical resistances.

The wire bending machine is available in different versions, with or without coil: wire bending capacity up to 10mm.

E-FLEX

|

Wire bending machine

BLM GROUP

Wire bending and forming machines

The E-FLEX is the new automatic single-head, all-electric, CNC wire bending machine.

Equipped with two clockwise and anticlockwise bending turrets, it is perfect for 3D bending and allows multiple bending technologies to be performed on the same part within the same cycle. Coil feeding ensures fully automatic operation.

The part is straightened out by a REVOLVER which provides a plurality of straightening units of various size and type which are always ready for use and preset to guarantee bending repeatability.

Chamfers can be added for perfect, burr-free cuts.

According to the fitted bending equipment and the required bend type, the machine can implemented various bending processing by exploiting its two turrets.

The cutting device is managed by an axis. Programming direction and stroke can be programmed to guarantee excellent appearance and closed part overlap.

3D visual graphic programming (VGP3D) and constant visual monitoring of the machining zone by means of cameras make the machine easy, comfortable and safe to use.

E-FLEX is particularly suited to machine parts with:

• very complex shapes with three-dimensional development

• parts with short developments

• parts using different bending technologies