AXILE Machine

Products

Agile Smart Machining

Machine tools

Machining centres

AXILE DC12

|

High speed machining centre

Buffalo Machinery Co., Ltd.

High speed machining centres

AXILE Double Column Type 5-Axis Machining Center, DC12 combines heavy cutting and high-speed 5-axis machining capabilities in one.

With built-in spindle of 20,000 rpm of HSK-A63 spindle taper with 90 tools (STD) and 120 tools (OPT), DC12 offers high-speed machining capacity. Moreover, DC12 also provides 16,000rpm spindle option of HSK-A100 spindle taper with 60 tools for users who are looking for high-torque to do hard material cutting.

DC12, profitable performer is especially excellent for precision machining for extra heavy parts with complex contouring.

AXILE-G6

|

High Speed machining center

Buffalo Machinery Co., Ltd.

High speed machining centres

One Compact Machine, Limitless Applications

With a rotary table diameter of 600 mm, the G6 is a compact vertical machining center designed for agile, smart machining of smaller workpieces requiring complex geometries and intricate features. This highly

versatile VMC delivers full 5-axis CNC machining, with the built-in spindle moving along the X,Y,Z-axis, and the table moving in rotary C-axis and swiveling A-axis.

The G6?s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes,

and maximum production efficiency.

In addition to the high-performance G6 model, AXILE also offers the G6 MT, which combines both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential

clamping errors, the G6 MT can efficiently machine a wider variety of parts, including cylindrical components.

AXILE-G8

|

High Speed machining center

Buffalo Machinery Co., Ltd.

High speed machining centres

5-Axis CNC Machine

The G8 design is based on an advanced gantry construction giving the most powerful structure to achieve the best working conditions when machining the most complex work pieces.

The powerful 5 axes simultaneous machining is provided by high dynamics from tool motion (3 axes) and working piece motion (2 axes). Both rotary axes in the table are driven by built-in motors with high torque!

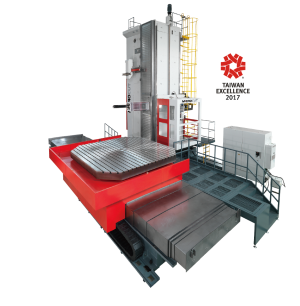

AXILE-V series

|

High Speed machining centre

Buffalo Machinery Co., Ltd.

High speed machining centres

The V series high-speed machining center provides Die / Mold solution for highly precise machining capability is realized by high spindle speed, fast acceleration/deceleration, and precision contour feed control. Machine frame is analyzed with the FEM system to ensure the optimum machine stability. V combines maximum productivity with a reasonable investment.

For more information, please visit our website.

Microcut-M Series

|

Vertical machining centre

Buffalo Machinery Co., Ltd.

Vertical machining centres

M series is a compact vertical machining center with high efficiency, high accuracy machining performance. Linear Guideways for higher speed and enhanced machining productivity. Wide selection of spindle speeds, automatic tool changers and more for various customers’ applications and needs, such as aerospace, medical engineering, automotive, general machining and mechanical engineering.

Boring machines

HBM-140RF

|

Boring and milling machine, gantry type

Buffalo Machinery Co., Ltd.

Boring and milling machines, gantry type

Intended for precision and high efficient coordinate boring, drilling, milling and thread cutting. The design allows machining of large and heavy work pieces with requirements of high tolerances, accuracy and smooth surfaces. Milling heads for different usages can be selected automatically!

HBM-140RT

|

Boring and milling machine, gantry type

Buffalo Machinery Co., Ltd.

Boring and milling machines, gantry type

With an extension of the working capacity, the HBM-140RT travelling column RAM type boring and milling center offers X/Y/Z axis travels up to 6500/4500/2000mm. Table size up to 3500x3500mm with a loading capacity of 40000kgs. It offers dia. 140mm spindle with a ram stroke of 800mm and a quill travel of 700mm. Advanced ram and spindle straightness control technology ensures ultra-precise machining while ram and W-axis are fully extended.

HBM-3

|

Boring and milling machine, gantry type

Buffalo Machinery Co., Ltd.

Boring and milling machines, gantry type

The boring and milling machine, HBM-3 is capable of both high-speed mold processing and low speed with high torque. This model provides 3000rpm ISO50 spindle, automatic 2 steps speed changer and high torque. The offering travel range includes 2200mm of X travel, 1600mm of Y and Z travel, and 550mm of W axis. The high rigidity and stability construction offers maximum productivity and builds the best profitable equipment.

HBM-3T

|

Boring and milling machine, gantry type

Buffalo Machinery Co., Ltd.

Boring and milling machines, gantry type

HBM-3T traveling column boring and milling center with powerful gearbox driven spindle dia. 110 mm provides high-speed with excellent power and torque. The machine's flexibility makes it useful for a variety of workpieces with loading capacity up to 8000kgs. The machine can be equipped with a wide selection of technological accessories that significantly expands the usability of it. Either Fanuc, Heidenhain or Siemens controls can be selected

HBM-4

|

Boring and milling machine, gantry type

Buffalo Machinery Co., Ltd.

Boring and milling machines, gantry type

HBM-4, the boring and milling machine is provided with a large working table for heavy loading capacity. Generous dimensioning of the hydraulic clamping system while enables the capacity for heavy cutting. Super rigid & compact Spindle headstock with cooling & lubrication oil supplied to all the thermal source in Spindle head to minimize its thermal expense.

HBM-4T

|

Boring and milling machine, gantry type

Buffalo Machinery Co., Ltd.

Boring and milling machines, gantry type

HBM-4T traveling column boring and milling center with powerful gearbox driven spindle dia. 130 mm provides high speed with excellent power and torque. The machine's flexibility makes it useful for a variety of workpieces with loading capacity up to 10000kgs. The machine can be equipped with a wide selection of technological accessories that significantly expands the usability of it. Either Fanuc, Heidenhain or Siemens controls can be selected

HBM-5T

|

Boring and milling machine, gantry type

Buffalo Machinery Co., Ltd.

Boring and milling machines, gantry type

HBM-5T traveling column boring and milling center with powerful gearbox driven spindle dia. 130 mm provides high-speed with excellent power and torque. The machine's flexibility makes it useful for a variety of workpieces with loading capacity up to 20000kgs. The machine can be equipped with a wide selection of technological accessories that significantly expands the usability of it. Either Fanuc, Heidenhain or Siemens controls can be selected.

HBM-5TL

|

Boring and milling machine, gantry type

Buffalo Machinery Co., Ltd.

Boring and milling machines, gantry type

Enlarged HBM-5TL traveling column boring and milling center with increased travel on X/Y/Z axes up to 5500mm/3200mm/2000mm and a bigger working table 2500x2500mm with a heavy loading capacity of 20000kgs. Dia. 130mm spindle driven by a powerful gearbox offers both high power and torque. The machine can be equipped with a wide selection of technological accessories that significantly increases the usability of the unit. Either Fanuc, Heidenhain or Siemens controls can be selected.

HM-RT/RTL

|

High speed boring machine

Buffalo Machinery Co., Ltd.

High speed boring machines

The high precision, great rigidity and excellent accessibility T-Type (moving column) machine with roto-translation table and high torque built-in spindle provide better metal removal rate. The Automatic Pallet Changer system can greatly increase manufacturing productivity. Applied Straightness Compensation Technology, the linearity of the RAM’s spindle and the accuracy of machining performance can be guaranteed.

Turning machines (lathes)

LD-52

|

Multi-spindle chucking automatic

Buffalo Machinery Co., Ltd.

Multi-spindle chucking automatics

LD-52 is Twin-Spindle Single Turret slant-bed lathe which is capable of multi-axis turning and milling. The machine is well equipped with twin spindles and single turret, live tooling, C-axis, Y-axis and is capable of producing high accuracy parts. Besides, this multi-functional LD series is ready to be implemented for automation. The tool setter, workpiece probe, and accessories allow further setup for the automated operation to reduce intensive labor costs.

LD-65

|

Multi-spindle chucking automatic

Buffalo Machinery Co., Ltd.

Multi-spindle chucking automatics

LD series is a high-quality twin spindle slant-bed turning lathe, not only can do complex turning and milling in one-setup but is also ideal for tasks requiring long time loading. It highly increases efficiency, productivity and meets the diversified tasking requirement of production.