COSCOM

Products

COSCOM Computer GmbH

Software for managing manufacturing systems

Virtual Machining Prozess-Lösung

The complete solution of CAD/CAM, simulation, DNC, as well as data and tool management

COSCOM virtual machining is a smart network of manufacturing process from CAD/CAM software, machine simulation, tool management, DNC - / CAM data management, as well as the cockpit for the production. Highlights & benefits:

-Complete software networking the entire production for maximum synergy and transparency

-Seamless data flow from ERP, PLM and design up to the machine for maximum process reliability

-Uniform database, CAM change service and information visualization for consistent transparency

This description was translated from German to English by "Bing Translator".

COSCOM Prozessberatung

|

Consultancy for production planning

COSCOM Computer GmbH

Automation

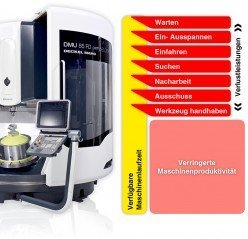

Developing the perfect production systematically - We support machining companies through our process consulting TPM- and LEAN-production approaches, production metrics (e.g. OEE), as well as modern manufacturing IT solutions.

The goal is perfect manufacturing with more transparent, responsive and economical processes as well as workflows. Process consulting from COSCOM makes this possible, in line with the motto "consulting services with implementation expertise", in 3 stages:

1. Individual product-neutral process consulting with manufacturing analysis.

Would you like to take a real close look at your manufacturing? Then COSCOM is the right partner for you! The individual and above all product-neutral COSCOM analysis is specially designed for mechanical engineering companies and companies in the machining industry. According to the premise of dialogue instead of monologue, your company-internal employees and COSCOM process consultants with many years of experience in the industry work together in the COSCOM workshop to develop an individual questionnaire within the scope of the analysis. No prefabricated standard questionnaires, but the self-developing workshop is the focus of the discussion. Our trained process consultants have many years of industry experience and communication skills. By asking precisely tailored questions about the individual production process, we are able to identify significant as well as smaller optimization potentials.

2. Demand-oriented evaluation - implementation competence included.

Goals of any production are: faster set-up - deliver improved quality - more efficient use of resources - higher machine uptime. Process consulting by COSCOM makes this possible, according to the motto "consulting service with implementation competence". Based on the results of the analysis, our manufacturing specialists develop a needs-based evaluation of the analysis discussions. The COSCOM product competence as well as the project experience in the implementation of homogeneous IT infrastructures allow for holistic optimization scenarios. Together with you, we develop the optimal software application around the CNC machine - for more profit before the chip! In addition, an individual profitability analysis (ROI) is worked out. The presentation can be done step by step - from convincing the decision makers to motivating the employees.

3. Management Summaray - Your "Roadmap" for Implementation.

As a result of the process consulting, the company is provided with a detailed summary based on the proven COSCOM OEE method with an individual analysis, target setting and action plan. "The person responsible for production takes home a detailed "master plan" for implementation. We will then be happy to accompany you in the subsequent implementation of the topics as a coach with our software products or our process solutions, so that you can safely achieve your goals!

Translated with DeepL