COSCOM

Products

CAM software

ProfiCAM VM

|

CAM software

COSCOM Computer GmbH

CAM software

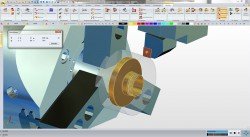

ProfiCAM VM - NC programming for turning and milling machines as well as mill (Millturn) - machinery creates consistent processes, minimize lead times and increases the reliability - for maximum quality, reliability and cost efficiency. ProfiCAM VM includes leading CAM technologies for the calculation of highly efficient toolpaths. NC-Joker's unique post processor concept allows for the maintenance and further development of the NC set output over the entire life cycle of a CNC machine. This means: existing customizations of NC set outputs can be extended at any time new processing strategies (cycles), additional machine axes as well as CNC-control updates.

This description was translated from German to English by "Bing Translator".

CAD/CAM Prozess-Lösung

|

CAM software

COSCOM Computer GmbH

CAM software

In focus: the efficient CAD/CAM-workflow

The COSCOM CAD/CAM process solution links the modules of CAD/CAM software, machine simulation, tool management and cockpit for the production with a focus on the best simulation in advance of cutting. Highlights & benefits:

-Universal concept of simulation with real data of the NC machine for meaningful simulation

-Central database for maximum data security and documentation to the simulation

-Simulation-enabled tool data, upgrade plans, clamping sketches and one Setup sheets

CAD/CAM virtual machining

A valuable simulation approach is characterized by a seamless integration of information. The simulation scenario must match the reality on the CNC machine (machine room, tension and tools).

The central database (cockpit for the production) is the information platform for real engine room simulations. The central database is automated via the CAD/CAM system with simulation information supplied. In a text-oriented machine programming (Doo-Wop) process work-arounds lead to simulation data based, without neglecting the documentation.

Simulation data for real Machinenraumsimulationen

NC program or tool paths

Tool list associated with tool graphics

Work piece zero point list

Raw and finished parts

Mounting situation

Machine model

The simulation results to the machine

The flow of information in the tool presetting (Assembly instructions), as well as to upgrade staff on the CNC machine (upgrade plan) is ensured by the central database (cockpit for the production).

This description was translated from German to English by "Bing Translator".