DATRON AG

Products

Smart Manufacturing Solutions

Machine tools

Milling machines

DATRON neo

|

DATRON neo

DATRON AG

High speed milling machines (HSC)

| Travel |

|

| 520 mm | |

| 420 mm | |

| 220 mm | |

| Machine characteristics |

|

| 740 kg | |

The DATRON neo is setting new standards in terms of quality, process reliability and user-friendliness. With the proven plug & play principle and the intuitive DATRON next software, users can work productively straight away, regardless of their level of experience. The excellent access to the work area makes it very easy to load and set up workpieces. Thanks to the integrated camera and the DATRON 3D probe, workpiece set-up is unmatched in terms of simplicity, speed and precision. The DATRON neo impresses with its high performance and dynamics while remaining extremely compact and versatile.

DATRON ShuttleLoad

|

Other milling machine

DATRON AG

Other milling machines

| Machine characteristics |

|

| 900 kg | |

Maximum efficiency and cost-effectiveness in production with simultaneous loading: make the best of your spindle run time by adding the optional DATRON ShuttleLoad to your DATRON MXCube. With the optional DATRON ShuttleLoad extension, the two independently controlled quick change tables move into and out of the workspace, enabling simultanoeous loading of the machine. Ideal for small to medium-sized workpieces with reduced chip volume.

DATRON ToolAssist

|

Other milling machine

DATRON AG

Other milling machines

The DATRON ToolAssist combines common tool systems and well-known CNC accessories for even more user-friendliness and efficient production: As the first external DATRON tool changer outside the machining area, it is automatically protected from chips. This increases the machining area in the machine room and improves accessibility, especially when loading by robots.

The DATRON ToolAssist with its unique tool changing system is available for the high-speed milling machines DATRON MXCube, DATRON M8Cube and DATRON MLCube.

DATRON ToolAssist sets new standards in terms of user friendliness and efficiency. With up to 143 tool slots, DATRON ToolAssist establishes optimum conditions for a greater variety of tools and the use of sister tools in series production. Being the first DATRON tool changer outside the machining area, it is automatically protected from chips and enables ergonomical loading and unloading at any time while operating the machine.

Efficient production:

- Up to 143 tool slots for a greater variety of tools and the use of sister tools in series production

- Simultaneous loading and unloading of tools during production

- Intelligent tool supply for fast tool changing

Reliability:

- Tool magazine protected from dirt and chips

- Safe tool changing by monitoring of collet chucks

- Increased availability of the machining system

Innovative operating concept:

- Interactive operation of the machining system guided by the DATRON next control system

- Intelligent tool organisation

- Ergonomical replacement of 5 tools simultaneously

DATRON MLCube

|

High speed milling machine (HSC)

DATRON AG

High speed milling machines (HSC)

The DATRON MLCube is the best choice for economical plate machining. With an improved chip concept, a stand-alone terminal for maximum flexibility, and the DATRON ToolAssist, the new DATRON MLCube machine concept offers a significant increase in productivity with even easier loading.

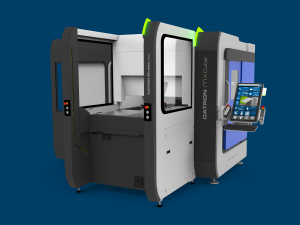

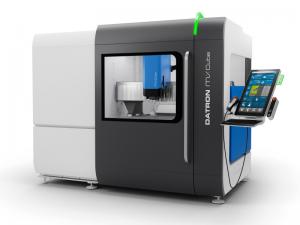

DATRON MXCube 4kW

|

High speed milling machine (HSC)

DATRON AG

High speed milling machines (HSC)

With the DATRON MXCube performance class, we present the premium segment of our high-speed portal machines!

The DATRON MXCube was especially developed for the execution of demanding HSC strategies and excels not only at removing high volumes of chips but also by achieving an excellent surface finish.

To meet your individual machining requirements, you can now choose the spindle power levels 4kW or 8kW.

DATRON Automation

|

Other milling machine

DATRON AG

Other milling machines

Automation Ready:

For future-oriented production

The DATRON automation portfolio offers efficient and individual solutions for future-oriented production. Automatic doors, interfaces to software and internal hardware, as well as external automation expand DATRON machine systems with DATRON next control.

Translated with DeepL

CNC milling machine M8Cube

|

M8Cube

DATRON AG

High speed milling machines (HSC)

The M8Cube is one of the latest additions to our wide range of compact high-speed CNC machines for any milling requirement. New controls, new features, ergonomic working environment and low operating cost - let our range of accessories and software features prove the difference.

It features a very large working area while keeping a small footprint, it is affordable with extremely low operating cost and has short set-up times. It provides you with new opportunities in milling, drilling and engraving. The M8Cube was engineered to process high-tech materials with small tools (Ø 0.1 mm to 20 mm).

The M8Cube is the top choice for the efficient machining of housings, profiles and panels made of aluminium and other nonferrous metals or composites. M8Cube stands for state-of-the-art milling technology "Made in Germany" for your production success.

CNC milling machine MLCube

|

MLCube

DATRON AG

High speed milling machines (HSC)

The DATRON MLCube is the best choice for cost-effective sheet machining, for example, for the production of front panels, housings, profiles and other aluminium workpieces milled in nested form. Other non-ferrous metals or composite materials can also be processed most efficiently with the MLCube. Its short setup times and its ability to use different clamping techniques simultaneously, its very low power consumption and its excellent price-performance ratio - even for low production volumes - provide long-term and extremely high profitability.

CNC milling machine MLCube LS

|

High speed milling machine (HSC)

DATRON AG

High speed milling machines (HSC)

Reliable, Large-Format and Highly Precise - Your benefits at a glance:

- Extremely large working area requiring little floor space

- New vacuum clamping technology with the possibility of electrically enabling/disabling different segments

- Available with table cutout for vertical clamping technology, appropriate for machining high components (optional)

- Contour smoothing package PerfectCut for fast, accurate and contour-faithful HSC milling with excellent surface quality: your machine is more powerful and stays ?fit? longer, even in cases of high-volume production (optional)

- New chip carriage design with allocation to multiple containers (stackable) to promote work ergonomics

- Linear measuring system:

- Improved precision in X and Y axis

DATRON MXCube

|

High speed milling machine (HSC)

DATRON AG

High speed milling machines (HSC)

The rigid structure, maximum dynamics and a powerful high-frequency spindle are ideal for modern HSC strategies and can combine high machining volume with outstanding surface finish. The completely redesigned machine with optimised chip concept offers a wide range of functions for operation in an industrial environment.