DVS TECHNOLOGY GROUP

Products

We Drive Future Mobility

Bonded abrasive products

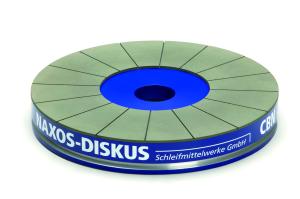

NAXOS-DISKUS CBN & Diamond Grinding Wheels

|

Grinding wheels

DVS TECHNOLOGY GROUP

Bonded abrasive products

Diamond and CBN are superior to all other materials as far as cutting edge consistency and wearresistance are concerned. Our CBN and diamond grinding wheels are produced for performing highest precision grinding operations with exceptionally good reproducibility. Specially coated CBN abrasive and the newly developed vitrified and resin bonding systems are the basis for the CBN and diamond grinding wheels from NAXOS-DISKUS. Our grinding wheels are available with a body made of steel, aluminium, aluminium wrought alloy, synthetic resin, ceramic or carbon fibre laminate. With our vitrified and synthetic resin bonded CBN and diamond abrasives, we can supply you a tool to rely on. It goes without saying that we design your custom-made grinding wheels according to your application. We can of course also produce special designs according to your wishes.

NAXOS-DISKUS CBN & Diamond Lateral Surface Grinding Wheels

|

Grinding wheels

DVS TECHNOLOGY GROUP

Bonded abrasive products

NAXOS DISKUS can look back on many years of experience in the manufacture of CBN and diamond surface grinding wheels. Our grinding wheels are used in the most different areas of metal machining and ceramics processing, e.g. for the grinding of piston rings. The advantages of these grinding wheels are their long service life and the high dimensional accuracy of the ground workpieces. Our grinding wheels can be optionally purchased with a base body made of steel or aluminium. With our ceramically or resin bonded CBN and diamond lateral surface grinding tools, we provide you with a tool that allows you to look into the future without having to worry about its condition.

NAXOS-DISKUS Centerless Grinding Wheels

|

Grinding wheels

DVS TECHNOLOGY GROUP

Bonded abrasive products

In this special application, one distinguishes between throughfeed grinding and plunge-cut grinding. Depending on the application, one can either select a single-part or a multi-part version which ensuresa better handling during the grinding wheel exchange, depending on the circumstances. It is precisely these transition points of multipart grinding wheels that require extensive knowledge during the construction and manufacture, since otherwise they might affect the grinding pattern. We can manufacture the different areas with different grain size and hardness in order to obtain a high chip removal rate on the feeding side and a good surface quality on the discharge side, especially in the case of throughfeed grinding.

NAXOS-DISKUS Conventional External Cylindrical Grinding Wheels

|

Grinding wheels

DVS TECHNOLOGY GROUP

Bonded abrasive products

Our conventional grinding wheels are manufactured according to customer request and application, and grinding wheels of all grain types are produced. The abrasive grain materials vary from corundum types to silicon carbide and up to microcrystalline sintered corundum, because every different grain type has other properties with regard to the treatment of different materials. Together with the grinding technicians of NAXOS-DISKUS, new specifications are constantly being created to meet customers’ specific application requirements. This type of grinding wheel is also very well suited for all sorts of profiled versions.

NAXOS-DISKUS Conventional Lateral Grinding Wheels

|

Grinding wheels

DVS TECHNOLOGY GROUP

Bonded abrasive products

In the area of conventional face grinding, we act as original equipment supplier for the famous double-sided lateral surface grinding machines of DISKUS WERKE Schleiftechnik. Due to this long-term cooperation, we can manufacture grinding wheels for every appropriate application. The field of application of the conventional grinding wheel comprises the automotive industry (from engine blocks to connecting rods), the punching industry, the watchmaking sector (blanks of watches) up to the grinding of skis! During the manufacture we attach greatimportance to a constant and high product quality and the dimensional accuracy of our grinding wheels at an incomparable priceperformance ratio.

NAXOS-DISKUS Crankshaft Grinding Wheels

|

Grinding wheels

DVS TECHNOLOGY GROUP

Bonded abrasive products

Vitrified bonds are usually used for this special type of grinding wheels. Depending on the grinding operation, the grinding wheel for bearing seats can be composed of one single layer or of three layers, in case the shoulders and the bearing seat are to be ground in one passage. We are able to manufacture these multi-layered grinding wheels very precisely. Due to the three-layered version, the durability of your crankshaft grinding wheel is increased thanks to the enhanced stability. The low manufacturing tolerances of the motor manufacturers bear witness to our know-how.

NAXOS-DISKUS Cylindrical Grinding Segments

|

Grinding Segments

DVS TECHNOLOGY GROUP

Bonded abrasive products

The grinding segments manufactured by our company are available in all imaginable shapes and sizes, and with all bondings and grain types you can think of. One main field of application of grinding segments is the use on a grinding wheel. The grinding segments can be manufactured with a base body (foot) onto which the grinding segments can be optimally mounted. With these grinding segments, even older machine types can be updated to become state-of-the-art grinding technology. Since the segments are machined in a set, we can guarantee an ideal concentricity of the segments. We are your partner in state-of-the-art technologies and also when it comes to the knowledge of well-proven methods.

NAXOS-DISKUS Gear Grinding Wheels

|

Grinding wheels

DVS TECHNOLOGY GROUP

Bonded abrasive products

Gear grinding wheels are used for grinding toothed wheels and tooth flanks. With regard to their specification and their profile, our gear grinding wheels are designed to precisely meet the requirements of the workpiece to be ground. If desired, we can provide the gear grinding wheels with a finished profile prior to delivery. The profile of the so-called grinding worms is identical with that of the workpiece, and a linear contact takes place across the entire width of the toothing. Due to our cooperation with machine manufacturers (e.g. Präwema), we can always keep you up to date with regard to gearing technology.

NAXOS-DISKUS Grinding Pins

|

Grinding Pins

DVS TECHNOLOGY GROUP

Bonded abrasive products

Our grinding pencils are used for internal cylindrical grinding. This type of grinding medium can be manufactured from conventional abrasives or in the form of a CBN grinding pencil. With CBN grinding pencils, a longer service life of the grinding tool can be achieved. Our grinding pencils prove their power especially if inaccessible areas are to be ground. You can rely on NAXOS-DISKUS grinding pencils even at very high speeds and under most difficult conditions. Since in many fields of application of the grinding pencils, the future lies in the time-saving simultaneous grinding, you should be able to count on one manufacturer that produces all the grinding media.

NAXOS-DISKUS Lateral Surface Grinding Segments

|

Grinding Segments

DVS TECHNOLOGY GROUP

Bonded abrasive products

NAXOS-DISKUS manufactures grinding segments for most different applications worldwide. The advantage of the grinding segments is their easy installation in the grinding machine. Moreover, they are very well suited for rough machining while ensuring best possible dimensional accuracy and surface quality. Especially noteworthy in this regard is the grinding of engine blocks. Furthermore, ball cages are ground on one side. As with all of our products, we pay attention to excellent properties, i. e. perfect cutting performance, low cuttingtemperature and excellent self-sharpening ability. Our separate production line for the segment manufacture is our investment for your perfect cut.

NAXOS-DISKUS Milling Disks

|

Milling Disks

DVS TECHNOLOGY GROUP

Bonded abrasive products

In the food sector, we can also score with quality. Our milling disks are very popular for the use in different applications. Not only the long service life, but also the dimensions of our products and our precisemanufacture create a large benefit for our customers all along the line. It goes without saying that we will define and provide you with a product which is tailor-made to suit your individual requirements. From mustard to cocoa or coffee – we manufacture milling disks for milling materials of every shape and size. We have many years of experience as original equipment supplier for the manufacturers of grinding mills. Our decade-long, constant quality also helps you to avoid product variations.

NAXOS-DISKUS Polishing Rolls

|

Polishing tool

DVS TECHNOLOGY GROUP

Bonded abrasive products

We manufacture our polishing rolls for the treatment of leather and leather-like materials. Our polishing rolls are also very well suited for the shaping of such materials. Even unusual sizes can be handled by our company without any problems. An optional metal core provides our polishing rolls with high stability and above-average durability. See for yourself our very flexible product specifications – which areexactly designed for industrial leather processing. NAXOS-DISKUS offers you products which enable you to reach new targets when it comes to cycle time, design and workmanship.

NAXOS-DISKUS XXL External Circular Grinding Wheels

|

Grinding wheels

DVS TECHNOLOGY GROUP

Bonded abrasive products

One of our numerous special fields of work is the manufacture of grinding wheels with a diameter of up to 1600 mm. Large crankshafts which are incorporated in marine engines are for example ground with these grinding wheels. These enormous dimensions require a high degree of specialization during the manufacture. The tolerances do not increase with the increasing size. On the contrary, they decrease proportionally and reach very demanding ranges. With our XXL external cylindrical grinding wheels, we can realize every desired size with the experience gained from 135 years of abrasive medium manufacture.

PRÄWEMA ORIGINAL Honing Ring

|

Honing Ring

DVS TECHNOLOGY GROUP

Bonded abrasive products

The original among PRÄWEMA gear honing tools results from combining the manufacturing experience gathered with over 10 million parts produced every year by DVS Technology, the Group‘s own series producer, with the close interaction with the design departments of PRÄWEMA Antriebstechnik and Naxos Diskus. Its extraordinary damping behaviour, enhanced tooth stability and a convincingly long tool life are proof of the outstanding efficiency of the PRÄWEMA ORIGINAL honing tool. Be it non-geared or with previously cut gears, DVS TOOLING tailors every honing tool to the needs of every user-specific process.