DVS TECHNOLOGY GROUP

Products

We Drive Future Mobility

DVS TECHNOLOGY GROUP

Honing machines

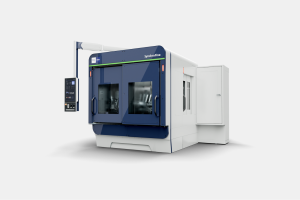

PRÄWEMA Synchrofine 205 HS (W)

In terms of the static and dynamic characteristics, the honing process places higher requirements on machine construction than any other machining process. For this reason superfluous axes were already eliminated on the predecessor model.

The “SynchroFine® 205 HS” represents a consistent advancement of this concept. The result is the familiar PRÄWEMA honing quality. The directly driven, digitally controlled spindles for tool and workpiece form the heart of the machine.

In combination with the high drive power installed, this allows extremely precise and rigid coupling between the tool and workpiece even at the highest speeds. The entire machine rests on a natural granite bed and the workpiece spindle is positioned on a separate granite support to minimize vibration and temperature influences. The X and Z axes are equipped with linear motors on the SynchroFine® 205 HS. This ensures higher dynamics for even better machining quality while simultaneously reducing the cycle times.

Präwema SynchroFine

|

Honing machine

DVS TECHNOLOGY GROUP

Honing machines

| 225 mm |

What makes SynchroFine unique is the compact design of all units. All units are mounted on a natural granite bed for optimal thermal and vibration-damping characteristics.

The digital and directly driven tool and workpiece spindles guarantee backlash-free drive and load reversal, as there is no need for mechanical transmission elements, such as toothed belts, gears, etc.

The machine is designed as a self-loading unit (pick-up principle) and is basically equipped with integrated handling units. The components can be fed individually. From simple manual loading through automation solutions with conveyor belts to robot cells with integrated camera functions from our sister company rbc robotics, we can use a wide range of automations according to your preferences and needs.

For even more efficiency, we can equip the system with two workpiece spindles in order to reduce non-productive times to a minimum.

The digital recording of operating parameters is also standard with the SynchroFine. It can be further expanded through various modules in order to analyze process data and thus continuously optimize processes

Highlights:

01

Optimized tool costs through flexible VSD dressing strategy

02

Sophisticated process reliability with short cycle times

03

Ultra-fine surfaces

04

Interlock free hard-fine machining

The digital and directly driven tool and workpiece spindles guarantee backlash-free drive and load reversal, as there is no need for mechanical transmission elements, such as toothed belts, gears, etc.

The machine is designed as a self-loading unit (pick-up principle) and is basically equipped with integrated handling units. The components can be fed individually. From simple manual loading through automation solutions with conveyor belts to robot cells with integrated camera functions from our sister company rbc robotics, we can use a wide range of automations according to your preferences and needs.

For even more efficiency, we can equip the system with two workpiece spindles in order to reduce non-productive times to a minimum.

The digital recording of operating parameters is also standard with the SynchroFine. It can be further expanded through various modules in order to analyze process data and thus continuously optimize processes

Highlights:

01

Optimized tool costs through flexible VSD dressing strategy

02

Sophisticated process reliability with short cycle times

03

Ultra-fine surfaces

04

Interlock free hard-fine machining