DVS TECHNOLOGY GROUP

Products

We Drive Future Mobility

DVS TECHNOLOGY GROUP

Thread grinding machines

BUDERUS CNC 335 G

CNC 335 G Female thread grinding machine The natural granite machine bed on the CNC 335 G female thread grinding machine guarantees high precision. Moreover, the CNC controlled radius dresser with diamond roller ensures maximum accuracy. It is possible to machine metric female threads as well as Whitworth, trapezoidal and special profiles, such as spherical collar nuts with Gothic or radius profile. The machine is equipped with a female thread grinding support with additional vertical axis. This guarantees that the middle of the wheel is always positioned at the center height, even when the length of the grinding arbor varies.

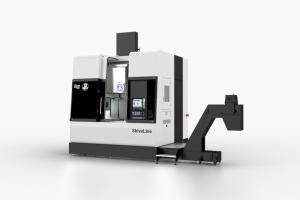

PITTLER SkiveLIne 315-1250

|

Universal machining centre

DVS TECHNOLOGY GROUP

Internal thread grinding machines

| Machine characteristics |

|

| 16000 kg | |

| 1250 mm | |

| 800 mm |

The PITTLER SkiveLine is a new type of skiving center with automation cell for complete machining of larger components up to a diameter of 1250mm. Based on the proven PITTLER vertical series, the new platform is geared to PITTLER's advanced Power Skiving gear cutting technology, which allows components to be skived both internally and externally. Components, such as the internal gears of the planetary gear, which are increasingly being used in future drives, can thus either be machined completely in one clamping operation or, in addition to gear cutting, be machined with upstream or downstream turning, milling or deburring processes. The PITTLER skiving center has also been optimized for fully automated series production: &Uml;via an innovative automation cell, the workspaces of up to two gear cutting centers are automatically supplied with workpieces, which minimizes space and investment requirements compared to robotic loading. In contrast to sequential machining on several machines, it is thus possible to respond economically to varying batch sizes. Translated with DeepL

Highlights:

01

6-axis – Complete internal and external machining: turning, milling, drilling, skiving, deburring, measuring, sharpening, backing, impact notching

02

Flexible automation: crane or manual loading, robot loading, optional shuttle loading and PITTLER automation cell

03

Automatic tool change through 16-part disk magazine

04

Secondary processing -> Pairs of machines

Highlights:

01

6-axis – Complete internal and external machining: turning, milling, drilling, skiving, deburring, measuring, sharpening, backing, impact notching

02

Flexible automation: crane or manual loading, robot loading, optional shuttle loading and PITTLER automation cell

03

Automatic tool change through 16-part disk magazine

04

Secondary processing -> Pairs of machines