DVS TECHNOLOGY GROUP

Products

We Drive Future Mobility

DVS TECHNOLOGY GROUP

Horizontal turning centres

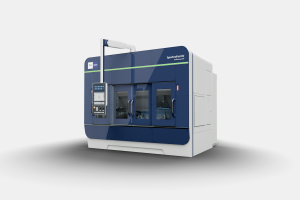

WMZ V 300

| Workspace |

|

| 300 mm | |

| 1500 mm | |

With two center-drive-heads for simultaneous end machining of shafts with a length up to max. 1.600 mm or with chuck construction for 4-axis turning. The product range V 300 is multifunctional and convenience through short loading and unloading times as well as simultaneous machining with two turrets. The V 300 series is particularly suitable with center-drive-heads if only both ends need to be machined and so the complete machining can be carried out in one clamping.

Highlights:

01

Turning, milling and gear cutting of shafts in only one set-up

02

Simultaneous machining of both shaft ends thanks to center drive technology

03

6-sided machining in main and counter spindle with up to four tool carriers

04

Automatic tool change in 7 seconds due to disc magazine

05

Integrated automation for fast workpiece change

Highlights:

01

Turning, milling and gear cutting of shafts in only one set-up

02

Simultaneous machining of both shaft ends thanks to center drive technology

03

6-sided machining in main and counter spindle with up to four tool carriers

04

Automatic tool change in 7 seconds due to disc magazine

05

Integrated automation for fast workpiece change

PITTLER PV SL 2 & PV SL 3

|

Vertical Pick Up Lathe

DVS TECHNOLOGY GROUP

Other lathes

| Workspace |

|

| 450 mm | |

| 280 mm | |

In the diameter range from 100 – 630 mm customers frequently have additional requirements - such as high unfinished part allowances for machining - high degree of complexity of parts - high part weights. The PV SL 2 / PV SL 3 machine platforms take such requirement profiles into consideration. The sturdy, high torque and high performance design ensures efficient production of parts even with high allowances or allowance variations. Various sizes of operating chambers are available for processing. This ensures sufficient space for auxiliary operations such as drilling, milling and grinding. In practice this means fewer chucking operations.High performance reliability In the diameter range from 100 – 630 mm customers frequently have additional requirements - such as high unfinished part allowances for machining - high degree of complexity of parts - high part weights. The PV SL 2 / PV SL 3 machine platforms take such requirement profiles into consideration. The sturdy, high torque and high performance design ensures efficient production of parts even with high allowances or allowance variations. Various sizes of operating chambers are available for processing. This ensures sufficient space for auxiliary operations such as drilling, milling and grinding. In practice this means fewer chucking operations.

Highlights:

01

Parallel and turning machining

02

Flexible workpiece feed from the rear of the machine into the automation room

03

Loading via storage table for up to 45 minutes of standalone processing

04

Automatic part separation – no defined placing of the raw and finished parts necessary

05

NC lift-off holder for brake disc machining

Highlights:

01

Parallel and turning machining

02

Flexible workpiece feed from the rear of the machine into the automation room

03

Loading via storage table for up to 45 minutes of standalone processing

04

Automatic part separation – no defined placing of the raw and finished parts necessary

05

NC lift-off holder for brake disc machining

PITTLER PV³

|

Complete machining center

DVS TECHNOLOGY GROUP

Other lathes

The innovative solution for complete machining of rotationally symmetrical and cubic parts, based on proven designs. The modular concept allows the machine to be produced with 1 or 2 independent spindles and with one or two cross slides. The PV³ combines technologies such as turning, drilling, thread cutting, milling, skiving, grooving or grinding and gear hobbing as well as hard turning and grinding including integrated quality check in a monitored process, all in one machine. Unique, patented tool carriers allow this high application flexibility in the part diameter range from 400 to 1,600 mm.

PRÄWEMA SynchroForm (V)

|

Gear hobbing machine

DVS TECHNOLOGY GROUP

Other lathes

The modular design of the SynchroForm V machine allows it to be adapted for the production of geared drive components. Set up as a single or twin spindle machine, it excels in series production with extremely profitable cycle times and high-precision machining results. Efficient complete machining in all areas of gearing in soft and hard fine machining can be achieved using the various technology modules. Your advantage: Versatile range of technologies for precise soft and hard fine machining Equipped with either one or two workpiece spindles to match unit requirements Efficient complete gearing machining of drive components

WMZ V 300

|

Turning Center

DVS TECHNOLOGY GROUP

Other lathes

| Workspace |

|

| 300 mm | |

| 1500 mm | |

With two center-drive-heads for simultaneous end machining of shafts with a length up to max. 1.600 mm or with chuck construction for 4-axis turning. The product range V 300 is multifunctional and convenience through short loading and unloading times as well as simultaneous machining with two turrets. The V 300 series is particularly suitable with center-drive-heads if only both ends need to be machined and so the complete machining can be carried out in one clamping.

Highlights:

01

Turning, milling and gear cutting of shafts in only one set-up

02

Simultaneous machining of both shaft ends thanks to center drive technology

03

6-sided machining in main and counter spindle with up to four tool carriers

04

Automatic tool change in 7 seconds due to disc magazine

05

Integrated automation for fast workpiece change

Highlights:

01

Turning, milling and gear cutting of shafts in only one set-up

02

Simultaneous machining of both shaft ends thanks to center drive technology

03

6-sided machining in main and counter spindle with up to four tool carriers

04

Automatic tool change in 7 seconds due to disc magazine

05

Integrated automation for fast workpiece change