ELHA-MASCHINENBAU

Products

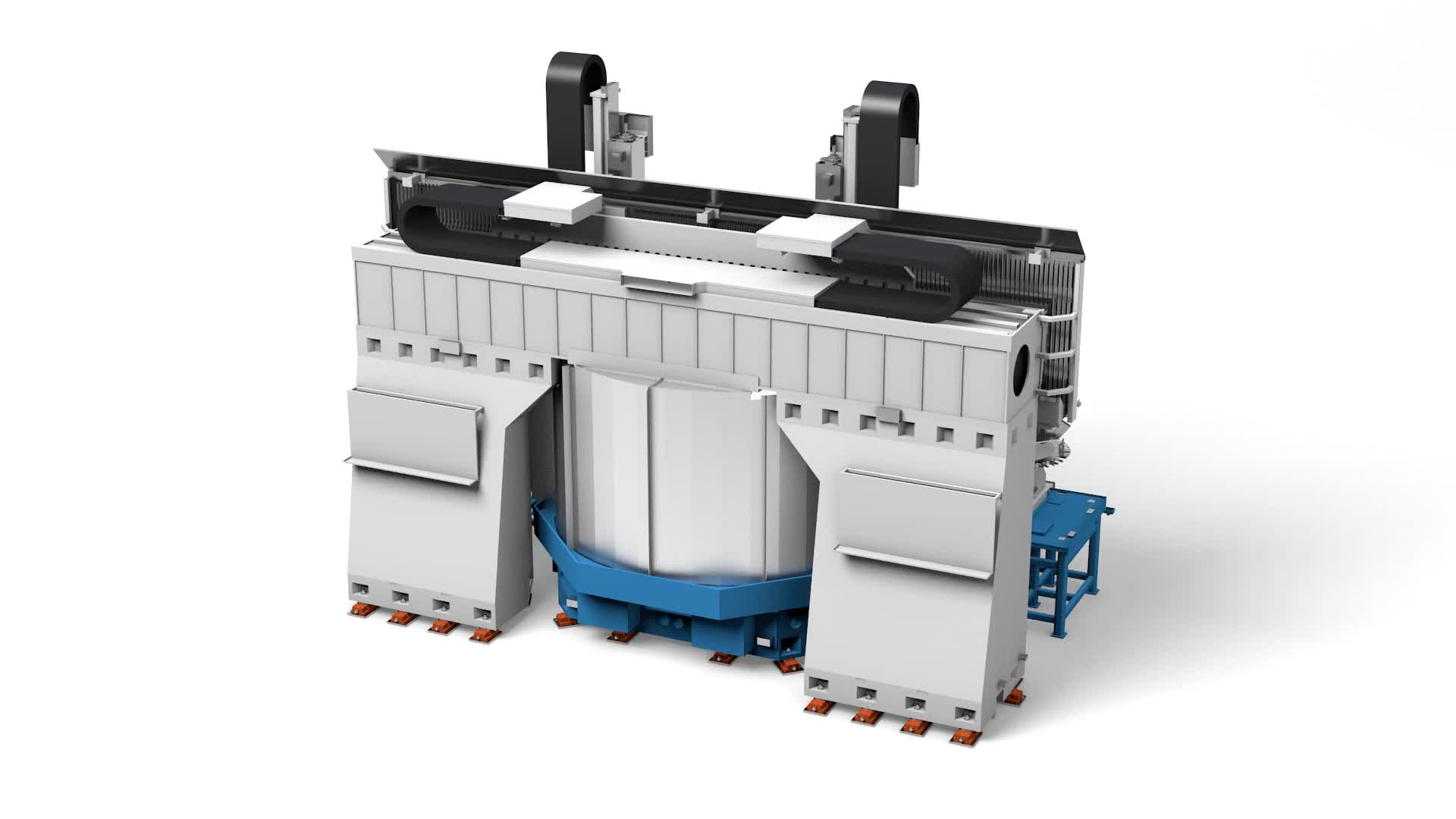

Machining centres

Turning and milling centres

VTM

|

Vertical turn-mill centers

ELHA-Maschinenbau Liemke KG

Turning and milling centres

Vertical multitasking machining of large rotary and cubic components. Highest precision, dynamics, flexibility as well as space and energy efficiency make the VTM the ideal problem solver for highly demanding manufacturing tasks in a wide range of applications.

Highlights

- ELHA SDD - the patented segment motor rotary table direct drive with maximum positional accuracy and dynamics

- Solid, FEM-calculated and space-saving machine base made of composite components

- Hydrostatic guidance and bearing of all linear and rotary axes

- Mature modular design with flexible, individual equipment options

- Stable, powerful RAM concept with innovative drive and attachment technology

- Wide range of variants for tool and attachment magazines

- High-precision 5-sided/5-axis simultaneous machining by means of double C-axis function

- High thermal stability and energy efficiency thanks to effective cooling concept with controlled heat dissipation and energy recovery options

Vertical machining centres

VTM

|

Vertical turn-mill centers

ELHA-Maschinenbau Liemke KG

Vertical machining centres

Vertical multitasking machining of large rotary and cubic components. Highest precision, dynamics, flexibility as well as space and energy efficiency make the VTM the ideal problem solver for highly demanding manufacturing tasks in a wide range of applications.

Highlights

- ELHA SDD - the patented segment motor rotary table direct drive with maximum positional accuracy and dynamics

- Solid, FEM-calculated and space-saving machine base made of composite components

- Hydrostatic guidance and bearing of all linear and rotary axes

- Mature modular design with flexible, individual equipment options

- Stable, powerful RAM concept with innovative drive and attachment technology

- Wide range of variants for tool and attachment magazines

- High-precision 5-sided/5-axis simultaneous machining by means of double C-axis function

- High thermal stability and energy efficiency thanks to effective cooling concept with controlled heat dissipation and energy recovery options

Other machining centres

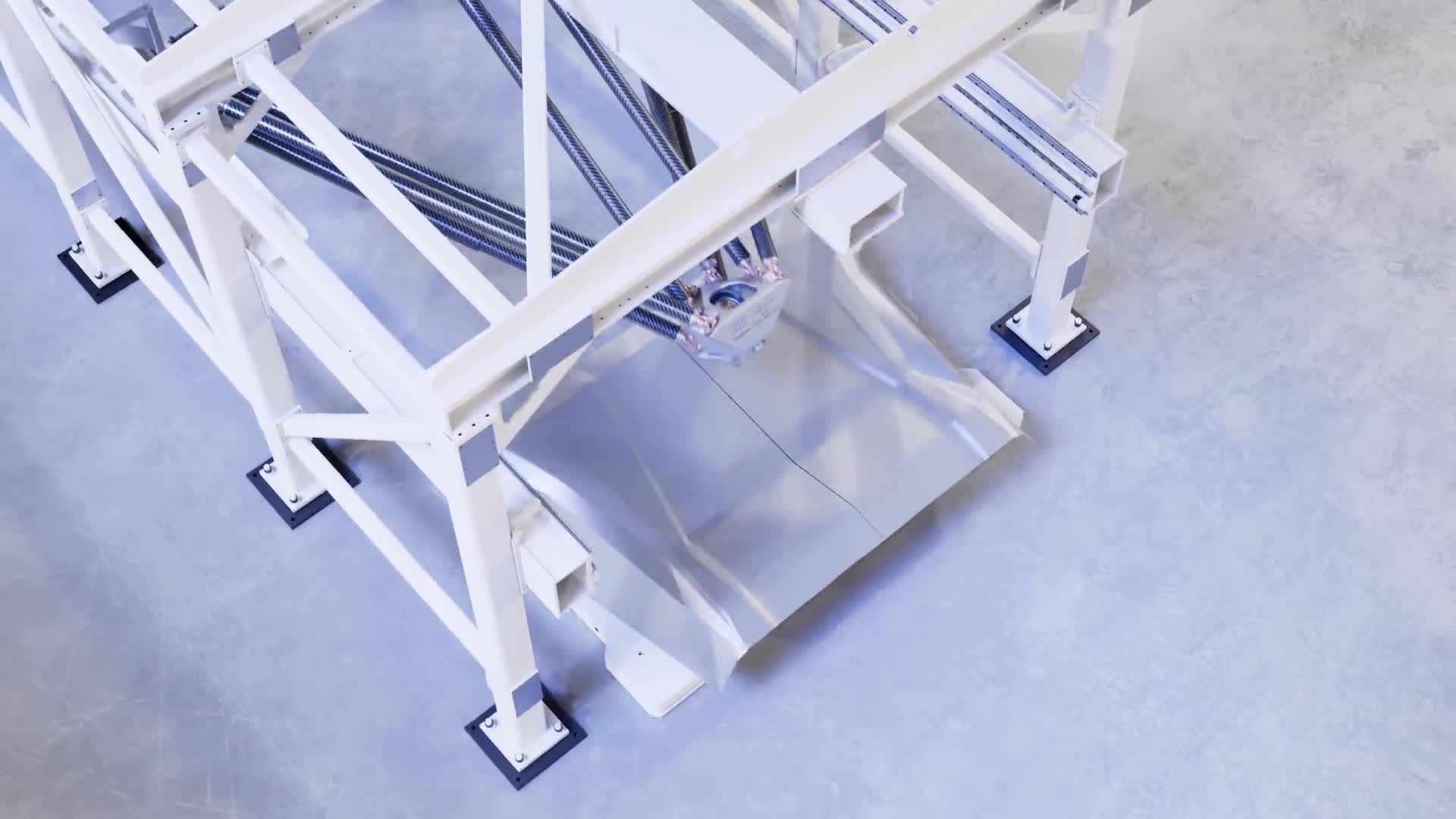

PKM

|

Parallelkinematik-Module

ELHA-Maschinenbau Liemke KG

Other machining centres

The PKM from ELHA-MASCHINENBAU closes the gap between classic machine tools and conventional arm robots. The solution offers a high degree of flexibility and can be integrated into other production lines. A large working area and extreme speed are the main features of the PKM. This was developed in collaboration with our partner Cognibotics.

Dynamics

- Developed to achieve the maximum dynamics with the least possible moving mass

- Up to 20 times less moving mass compared to classic machine tools

- Tool centre speed up to 170m/min

- Acceleration of the tool centre up to 2.5G depending on the application carrier (2.5G up to 40kg)

Precision

- Volumetric calibration by laser tracker

- Optional: integrated accuracy check and recalibration

- Repeat positioning accuracy up to 5µm

- Tool path accuracy in the entire working range up to 0.04mm (without process forces)

- Master-slave crosshead drives

- Backlash-free cardan joints and drives

Working area

- up to 3m in width, 2m in height, any length

- Configurable via rod lengths

- Horizontal working range possible

Flexibility

- Several parallel kinematics possible on one rail system

- Integration of workpiece guiding axes

- Any applications on the end effector

Sustainability / Maintenance

- Low number of wearing parts

- Low energy consumption due to low moving mass

- Energy surpluses during braking are fed back into the grid

Horizontal machining centres

SMX 5224 Horizontal 5-Axis Special Machining Center for Titan Cutting

|

Horizontal machining centre

ELHA-Maschinenbau Liemke KG

Horizontal machining centres

This new 5-axis special horizontal machining center stands for a whole new generation of ultra-robust and high-performance machines with outstanding features for the machining of most heavy-duty materials like titanium, Inconel and other materials and alloys primarily used in the aerospace sector.

This machine also uses the hydrostatic guided Z-axis-ram already known from our large Production Module series FM 4+X. The excellent vibration-absorbing and stabilizing features of this axis as well as the high-performance milling drive with a 37 kW strong HSK-A 125 in combination with the base machine made of composite-material result in record setting metal cutting capacities, precision and finish qualities! Thanks to the 3000 mm long and 1000 mm wide swing rotary table with an integrated rotary table of 1000 mm a wide work piece range of chassis parts up to large structural components can be machined, not only for the aerospace sector.

Turning and milling centres

SPX 5111 Turn-Mill Machining Center

|

Turning and milling centre

ELHA-Maschinenbau Liemke KG

Turning and milling centres

This machine is specially designed for the machining of printing rollers (max. Ø 800 mm; max. 2000 mm long). The range of machining comprises turn-milling of the lateral surface, reaming and drilling. This machine especially stands out by its high-precision, high heat-resistance and excellent damping features. With the heavy HSK 160 ? main spindle unit (150 kW) the machining priorities lie in turn-milling and reaming. This unit is equipped with a disk magazine of 14 slots. With the dynamic HSK 100 ram unit (50 kW) mainly drill machining takes place. This unit is equipped with an oval reciprocating feeder of 40 slots. Tool change is carried out by one double-gripper each.

The centering- and clamping units (X1- and X2-axes) travel separately during loading- and unloading operations. During machining the X-axes are electronically coupled. The axes of rotation (A1 and A2) are driven on both sides and also electronically coupled.

Other machining centres

FM Smart

|

Transfer Centers

ELHA-Maschinenbau Liemke KG

Other machining centres

ELHA-MASCHINENBAU has been known for many years as the market leader for highly productive transfer centers, with a focus on large-scale automotive production. With the FM SMART series, ELHA offers unprecedented flexibility in multi-spindle machining for transfer centers and thus represents an alternative to conventional machining centers.

Ideal concept for:

- Medium to high volumes

- Small and medium-sized workpieces

- Fastest possible changeover

- Optimal for light metals, (stainless) steels as well as casting and forging alloys