ELHA-MASCHINENBAU

Products

Other machining centres

FM Smart

|

Transfer Centers

ELHA-Maschinenbau Liemke KG

Other machining centres

ELHA-MASCHINENBAU has been known for many years as the market leader for highly productive transfer centers, with a focus on large-scale automotive production. With the FM SMART series, ELHA offers unprecedented flexibility in multi-spindle machining for transfer centers and thus represents an alternative to conventional machining centers.

Ideal concept for:

- Medium to high volumes

- Small and medium-sized workpieces

- Fastest possible changeover

- Optimal for light metals, (stainless) steels as well as casting and forging alloys

PKM

|

Parallelkinematik-Module

ELHA-Maschinenbau Liemke KG

Other machining centres

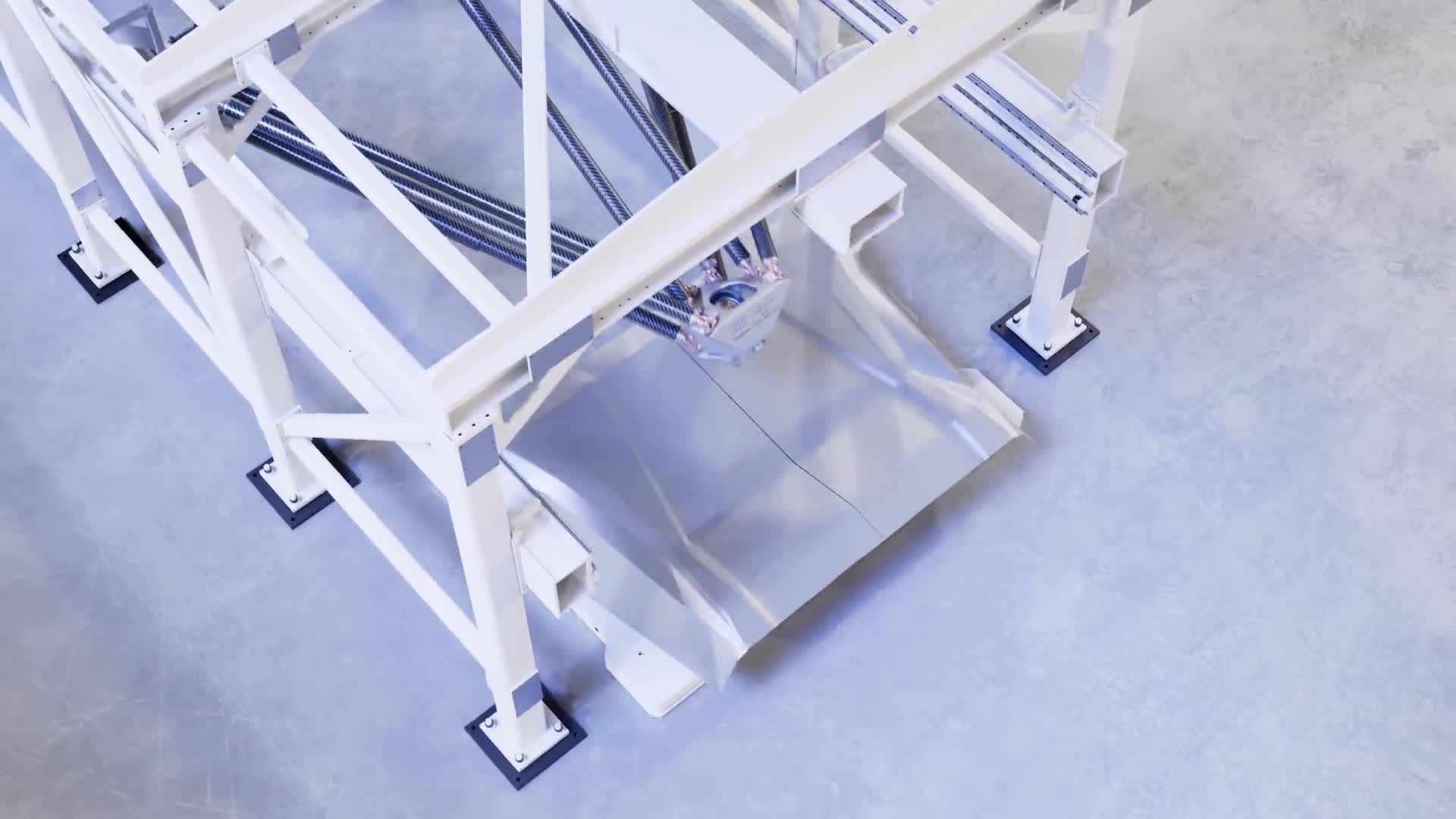

The PKM from ELHA-MASCHINENBAU closes the gap between classic machine tools and conventional arm robots. The solution offers a high degree of flexibility and can be integrated into other production lines. A large working area and extreme speed are the main features of the PKM. This was developed in collaboration with our partner Cognibotics.

Dynamics

- Developed to achieve the maximum dynamics with the least possible moving mass

- Up to 20 times less moving mass compared to classic machine tools

- Tool centre speed up to 170m/min

- Acceleration of the tool centre up to 2.5G depending on the application carrier (2.5G up to 40kg)

Precision

- Volumetric calibration by laser tracker

- Optional: integrated accuracy check and recalibration

- Repeat positioning accuracy up to 5µm

- Tool path accuracy in the entire working range up to 0.04mm (without process forces)

- Master-slave crosshead drives

- Backlash-free cardan joints and drives

Working area

- up to 3m in width, 2m in height, any length

- Configurable via rod lengths

- Horizontal working range possible

Flexibility

- Several parallel kinematics possible on one rail system

- Integration of workpiece guiding axes

- Any applications on the end effector

Sustainability / Maintenance

- Low number of wearing parts

- Low energy consumption due to low moving mass

- Energy surpluses during braking are fed back into the grid