EMAG

Products

Electroerosive and electrochemical machines

Electrochemical machine tools

PI 800

|

Electrochemical machine tool

EMAG GmbH & Co.KG

Electrochemical machine tools

With the PI modular machine platform, EMAG?s successful concept, i.e. same basic structure combined with customized technology, now also makes inroads at EMAG ECM. This offers you maximum flexibility for your machining projects in the area of electrochemical machining (ECM/PECM).

The right module for each application in electrochemical machining.

Electrochemical machining (ECM or PECM) can be used to machine a great number of different workpieces. Which technology comes to be used depends on the requirements of the workpiece. ECM can be implemented for deburring, drilling, broaching or even for gear cutting. If you want to achieve a high level of reproduction accuracy, then PECM is the right choice.

EMAG ECM already offers highly specialized machine solutions for both technologies, which are implemented for a wide variety of industries throughout the world. Above all, ECM and PECM are implemented wherever demanding materials (e.g. very hard) are to be machined or if material removal technologies reach their limits or simply are too expensive, e.g. if a burr and chip-free component can only be achieved through elaborate finishing.

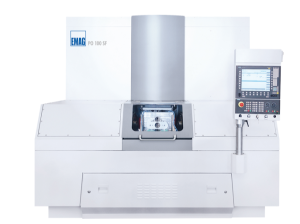

PO 100 SF

|

(P)ECM Machine

EMAG GmbH & Co.KG

Electrochemical machine tools

The economical solution for the complex machining of turbine blades

Electro-chemical Machining (ECM) is the generic term used to describe various process variants.

The ECM process manufactures workpieces through the electrolytic dissolution of metal. The process is used in the aerospace, automotive, medical, micro-system and energy industries. Almost all metals, even exotic materials such as nickel-based and titanium alloys or tempered materials can be easily machined using this process.

The drawbacks of conventional metalworking, such as tool wear, mechanical stress, micro-cracking from heat input, oxidation coatings or subsequent deburring work do not occur with this non-contact machining process. ECM features material removal without any inherent stresses, soft transitions and smooth finishes.