EMAG

Products

EMAG GmbH & Co.KG

Vertical turning machines

VL 6

Vertical Lathe for the Machining of Heavy Workpieces up to 300 mm in Diameter.

The VL 6 vertical lathe machine offers the same features as the newest EMAG modular designs in a vertical turning machine for larger, heavy workpieces. Equipped with a standard workpiece conveyor and pick-up spindle, the cnc lathe machine loads itself with minimized chip-to-chip times. With a machine base made of the polymer concrete MINERALIT®, a material well-known for its excellent damping quality, it offers extended tool life and outstanding surface finishes.

VL 4

|

Vertical turning machine

EMAG GmbH & Co.KG

Vertical turning machines

Vertical turning center VL 4 for chucked components up to 200 mm in diameter

The VL 4 vertical turning center is able to machine workpieces having a maximum diameter of up to 200 mm. The VL 4 is one of EMAG's modular turning centers that stand out by their very compact design. Like all vertical turning centers in this series, the VL 4 also features an integrated pick-up automation system.

VL 2

|

Vertical turning machine with pick-up spindle

EMAG GmbH & Co.KG

Vertical turning machines

VL 2 ? Vertical Pick-Up Turning Machine for Chucked Components up to 100 mm in Diameter

A stable machine structure, dynamic axes and ease of operation - these are the outstanding features of the VL series vertical turning machines. Based on a completely new modular machine concept, VL 2 vertical lathes make it possible to utilize various production technologies for soft and hard machining with integrated automation and a pick-up spindle, all while providing the best value for the investment.

EDNA IOT-READY EX-WORKS: Get started with data-optimized production with VL series

Using data analysis, unnecessary downtimes ? due to component wear or, in the worst case, due to the failure of a machine ? can be reduced or even avoided entirely. Productivity increases of over 10% are the rule here. To make entering the world of data-optimized production as easy as possible for our customers, all the machines of the VL Series now come standard in an IoT-ready state. This means that data analysis on the machines can be started virtually immediately.

VL 3 DUO Twin-Spindle Turning Machine

|

Twin-Spindle Turning Machine for the highly productive manufacturing of chucked parts

EMAG GmbH & Co.KG

Vertical turning machines

EMAG has extended the product range of the extremely successful VL series in the form of the VL 3 DUO, a twin-spindle machine solution for efficient manufacturing of chucked parts with a maximum diameter of 150 mm.

The VL 3 Duo design incorporates technological developments from EMAG over the last few years including pick-up and TrackMotion automation systems and modular design. These advancements are paired to create a highly productive manufacturing system that delivers maximum productivity with the smallest possible footprint.

VLC 200 GT

|

Vertical Turning Machine for hard turning, external grinding and internal grinding

EMAG GmbH & Co.KG

Vertical turning machines

Vertical turning and grinding ? a combination that has everything. The VLC 200 GT combines the benefits of vertical hard turning with those of grinding ? on a single machine and in a single clamping operation.

The VLC 200 GT is specially designed for precise, process-reliable and cost-effective manufacturing in medium- and large-scale production. Typical workpieces machined on the VLC 200 GT include gear wheels, sprocket wheels, sliding sleeves, parts for CVT gears, bearing rings and piston rings.

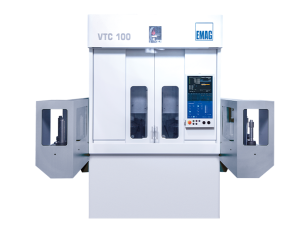

VTC 100

|

Universal Automatic Lathe

EMAG GmbH & Co.KG

Vertical turning machines

The strength of the VTC 100 Vertical Turning Machine lies in the production of large quantities of shafts with diameters up to 400 mm. Full integration into the EMAG machine concept including automatic loading and unloading of the workpieces offers a manufacturing system that is characterized by short travel distances and fast loading of via the turret. This is complemented by a powerful main spindle (34 kW, 144 Nm, 6000 rpm).

VTC 100 GT

|

Vertical turning and grinding centers - shafts

EMAG GmbH & Co.KG

Vertical turning machines

VTC 100 GT ? Small, compact shaft manufacturing cell

The VTC 100 GT turning and grinding machine ensures fast cycles for hard turning and grinding. The tool turret completes all turning operations, while the grinding takes place at a second station. Thus, the VTC 100 GT multi-functional machine is the perfect production tool for the complete machining of cylindrical bearing seats or shoulders and grooves, for example. Machined in a single clamping, true running errors resulting from separate clamping operations are reduced.

VT 2

|

Turning machine for vertical 4-axis shaft machining

EMAG GmbH & Co.KG

Vertical turning machines

VT 2 - The turning machine for vertical 4-axis shaft machining

Where shaft machining involves large numbers of workpieces, the first choice must be the VT series of turning machines. In the machining of shafts on turning machines the focus is on the speed of the process, whereby both loading / unloading and the machining cycle need to be very fast. This optimal requirement is fulfilled with the VT 2 turning machines.

Four axes, short travels, powerful mainspindle ? these are the strengths of the VT 2 turning machines. The full impact can be best felt where the component batches are large. Of decisive importance in the use of these turning machines is the ?two-sided? machining process, which massively reduces the machining time on the VT 2 turning machine.

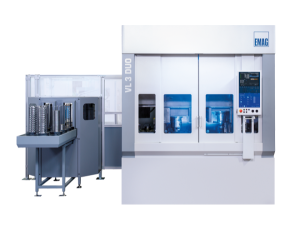

VM 9

|

Vertical Turning Center

EMAG GmbH & Co.KG

Vertical turning machines

VM 9 Vertical Turning Center for the Manufacture of Large Components

With the new VM 9 vertical turning center, EMAG has introduced a platform that covers a broad spectrum of applications thanks to the combined turning, milling and drilling technologies and intelligent machine design. The highly accessible machining area and workpiece spindle fitted at the bottom ensure short tooling times and maximum flexibility in the production of large components.