EMCO GmbH

Products

Machining centres

Vertical machining centres

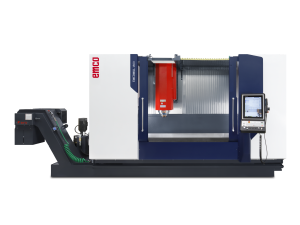

Vertical Machining Center EMCOMILL 1800

|

Vertical Machining Center

EMCO GmbH

Vertical machining centres

HIGHLIGHTS

/ High-performance milling spindles

/ Flexible tool system

/ Large work area with wide machine doors

/ Solid fixed table for workpiece weights up to 1500 kg

/ State-of-the-art control technology from Siemens, Heidenhain, Fanuc

/ Large number of options

/ Best price-performance ratio

/ Made in the Heart of Europe

EQUIPMENT

/ Mechanical or motor spindle

/ 30 x tool magazine (opt. 40 or 60)

/ Fast double changing arm

/ On request rotary table as 4th axis

/ Heidenhain, Siemens or Fanuc control

OPTIONS

/ Tool magazine with 40 or 60 stations

/ Tool holder ISO 40 / BT 40 / HSK -A63

/ NC -rotary table

/ 4th axis

/ Glass scales in all axes

/ Handwheel

/ Alarm status lamp

/ Control cabinet cooling unit

/ Automatic tool measuring

/ Coolant and air through the spindle

/ Bandpass filters with high pressure pumps

Vertical Machining Center EMCOMILL 1200

|

Vertical Machining Center

EMCO GmbH

Vertical machining centres

HIGHLIGHTS

/ High-performance milling spindles

/ Flexible tool system

/ Large work area with wide machine doors

/ Solid fixed table for workpiece weights up to 1500 kg

/ State-of-the-art control technology from Siemens, Heidenhain, Fanuc

/ Large number of options

/ Best price-performance ratio

/ Made in the Heart of Europe

EQUIPMENT

/ Mechanical or motor spindle

/ 30 x tool magazine (opt. 40 or 60)

/ Fast double changing arm

/ On request rotary table as 4th axis

/ Heidenhain, Siemens or Fanuc control

OPTIONS

/ Tool magazine with 40 or 60 stations

/ Tool holder ISO 40 / BT 40 / HSK -A63

/ NC -rotary table

/ 4th axis

/ Glass scales in all axes

/ Handwheel

/ Alarm status lamp

/ Control cabinet cooling unit

/ Automatic tool measuring

/ Coolant and air through the spindle

/ Bandpass filters with high pressure pumps

VERTICAL TURN 160

|

Vertical machining centre

EMCO GmbH

Vertical machining centres

HIGHLIGHTS

/ Robust, thermally stable machine concept

/ State-of-the-art drive technology from Siemens

/ Integrated hollow spindle drive with 600 Nm

/ BG 55/45 linear guides for maximum stability

/ Digital drive technology and high rapid traverse rates reduce main and auxiliary times

/ Conversion-friendly and very accessible work area

/ Y-axis with +/- 90 mm

/ Wide range of automation options: Automation designed for diameters up to 400 mm

/ Right and left machine versions

/ Complete machining (OP 10 + OP 20) for high flexibility

/ Made in the Heart of Europe

EQUIPMENT

/ Highly dynamic drive unit

/ Two track loading, quick and flexible automation with short cycle times

/ Chip-to-chip times up to 5.5 sec.

/ Small footprint

/ Strong guide rail concept for maximum stability / BG 45

/ Driven tools and Y axis +/- 65 mm Siemens controller 828D

/ Made in the Heart of Europe

VERTICAL TURN 260

|

Vertical machining centre

EMCO GmbH

Vertical machining centres

HIGHLIGHTS

/ Powerful main spindle with high torque for short cycle times

/ 2 independent tool systems: turret + multi-functional plate

/ Pick-up concept: Quick loading through direct pick-up of raw materials by the conveyor belt using the spindle

/ Optimal access to the work area

/ Chip conveyer with integrated coolant device as standard

EUQIPMENT

/ Designed for heavy-duty machining

/ Small footprintFree chip fall

/ Driven tools and Y axis optionally

/ Integrated self-loading system

/ Cutting-edge Siemens control

/ Made in the Heart of Europe

VERTICAL TURN 400

|

Vertical machining centre

EMCO GmbH

Vertical machining centres

HIGHLIGHTS

/ Robust, thermally stable machine concept

/ Latest drive technology from Siemens

/ Linear guides size 55/45 for maximum stability

/ Digital drive technology and high traverse speeds to reduce main and ancillary times

/ Machining compartment that is easy to change and easily accessible

/ + / - 90 mm Y axis

Multiple automation optionsAttractive price-performance ratio

EQUIPMENT

/ Fulfills complete machining of complex, heavy workpieces up to 400 mm diameter and 40 kg

/ Linear Guides size 55/45 for maximum stability

/ Driven tools and multi-function panel optionally

/ Modern Siemens control technology

/ Made in the Heart of Europe

Vertical Machining Center EMCOMILL 750

|

Vertical Machining Center

EMCO GmbH

Vertical machining centres

DESTACADOS

/ Husillos de fresado de alto rendimiento

/ Sistema de herramientas flexible

/ Gran área de trabajo con amplias puertas de máquina

/ Sólida mesa fija para pesos de pieza de hasta 800 kg

/ Tecnología de control de última generación de Siemens, Heidenhain, Fanuc

/ Gran número de opciones

/ La mejor relación calidad-precio

/ Fabricado en el corazón de Europa

EQUIPAMIENTO

/ Husillos de fresado de alto rendimiento

/ Almacén de 30 herramientas (opc. 40 ó 60)

/ Desbloqueo rápido con pinza doble

/ A petición mesa giratoria como 4º eje

/ Control Heidenhain, Siemens o Fanuc

OPCIONES

/ Almacén de herramientas con 40 ó 60 estaciones

/ Portaherramientas ISO 40 / BT 40 / HSK -A63

/ NC -mesa giratoria

/ 4º eje

/ Escalas de cristal en todos los ejes

/ H y rueda

/ Lámpara de estado de alarma

/ Unidad de refrigeración del armario eléctrico

/ Medición automática de herramientas

/ Refrigerante y aire a través del husillo

/ Filtros de paso de banda con bombas de alta presión

Vertical Machining Center EMCOMILL E350

|

Vertical Machining Center

EMCO GmbH

Vertical machining centres

HIGHLIGHTS

/ CNC Milling Machine with highest thermostability and optimal machining accuracy

/ Cutting-edge control technology from Siemens with JobShop programming software

/ Very attractive price-performance ratio

/ Top European quality ? Made in the Heart of Europe

EQUIPMENT

/ Mechanical spindle

/ 20-fold tool magazine

/ Fast two-arm changer

/ Optionally dividing unit (4th axis)

/ Siemens control

OPTIONS

/ 4th axis

/ Electronic handwheel

/ Automatic tool and workpiece measurement

/ Automatic door

/ Triple indicator lamp

Universal machining centres

UMILL 630

|

Universal machining centre

EMCO GmbH

Universal machining centres

HIGHLIGHTS

/ 5-axis simultaneous machining

/ Maximum thermostability

/ Maximum machining precision

/ Modern moving column concept with optimum accessibility

/ Solid swivel-rotary table with torque motors, direct measuring systems and front support, dimensions 630 x 500 mm provides high stability and precision

/ Swivelling range B-axis +/- 100

/ Standard linear scales in X-Y-Z

/ State-of-the-art control technology from Siemens or Heidenhain

/ Optimum chip disposal

/ Made in the Heart of Europe

EQUIPMENT

/ Motor spindle 15000 rpm

/ 30 (optionally 60/90) tool magazine

/ Siemens or Heidenhain control system

/ EMCONNECT - Digital Process Assistant (Sinumerik ONE)

UMILL 750

|

Universal machining centre

EMCO GmbH

Universal machining centres

HIGHLIGHTS

/ 5-axis simultaneous machining

/ Top thermostability

/ Top machining precision

/ Modern moving column concept with optimal accessibility

/ Solid swivel-rotary table with torque motors, direct measuring systems and front support, dimensions of 750 x 600 mm provide high stability and precision

/ Wide swivelling range +/- 100°

/ Standard linear scales in X-Y-Z

/ Cutting-edge control technology from Siemens or Heidenhain

/ Extensive options such as 60 / 90 tool stations magazine

/ Optimal chip removal

/ Made in the Heart of Europe

EQUIPMENT

/ Motor-Spindle 15000 rpm

/ Tool changer with 40 (optional 60/90) tool stations

/ Siemens- or Heidenhain control

/ EMCONNECT available for Sinumerik ONE

Turning and milling centres

HYPERTURN 65 PM G2

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

HIGHLIGHTS

/ High dynamics due to state-of-the-art spindle motor technology

/ All spindles liquid-cooled for optimum thermostability

/ High productivity due to short tool change times

/ Both tool systems can be used on both spindles

/ Bed design for maximum stability and oscillation damping

/ Excellent repeatability due to linear guides

/ Short set-up times due to ease of access to work area

EQUIPMENT

/ Main- and counter spindle, milling spindle, B and Y axis

/ Additional tool turret with milling drive and Y axis

/ 40-, 80-, 120-slot chain-type tool magazine

/ Tool magazin and control unit ergonomically placed

/ Max. bar stock diameter 65 (102) mm

/ EMCONNECT - Digital Process Assistant (Sinumerik ONE)

Turning/Milling Centre Hyperturn 65 Powermill High Performance

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

Equipped with two turning spindles, a powerful milling spindle including a tool changer and a 40-slot magazine as well as with two lower tool turrets featuring 12 driven positions each, the new HYPERTURN 65 Powermill HP (HIGH PERFORMANCE) allows for maximum productivity, especially when

it comes to the efficient production of small and medium-sized series with a high degree of variance.

EMCO HYPERTURN 110

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

HIGHLIGHTS

/ 2x A2-8" water-cooled main and counter spindles

/ 2x A2-11" powerful main and counter spindle

/ 2x 12-cavity tool turret with VDI 40 quick-change system

/ Optionally with BMT turret and direct drive up to 6000 rpm

/ Y-axes for machining complex turned and milled parts

/ Bar feed up to ø 95/110 mm

/ Optimum chip flow and operator-friendly work area

/ Highest drive and control performance

EQUIPMENT

/ 2 spindlesC axis

/ 2 tool turrets

/ Powerful milling spindle

/ Driven tools on both turrets

HYPERTURN 100

|

Turning and milling centre

EMCO Italy

Turning and milling centres

HIGHLIGHTS

/ Automatic tool presettings and workpiece measuring probes

/ One or more NC steady rests

/ 40 / 100 tool magazine stations

/ Flexible milling spindle with 12000 rpm

/ Boring bar pick-up system

/ 5-axis simultaneous machining

/ Coolant high pressure 80 bar

/ Virtual machine collision monitoring

/ EMCO REMOTE SUPPORT

/ Tool breakage monitoring

EQUIPMENT

/ Main and counter spindle for turning and milling operations

/ Milling spindle for turning, drilling and milling operations

/ Flexible milling spindle with 12,000 rpm

/ 40 / 100 tool stations

/ Boring bar pick-up system

/ EMCONNECT - Digital Process Assistant (Sinumerik ONE)

HYPERTURN 200 Powermill

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

HIGHLIGHTS

/ Very large working area for complete machining of workpieces up to a turning diameter of 1000 mm with a maximum length of 6100 mm

/ Dynamic and precise B-axis with high torque and power

/ Two versions of milling spindles with 6500 or 10000 rpm, with HSK-T100 or PSC80 (Capto C8)

/ Multi-tasking and multi-technology: Sinumerik ONE

/ Main spindle and counter spindle: high-performance machining with vibration-damped boring bar up to 1500 mm, including a special magazine (optional)

/ Automatic tool presets and workpiece measuring probe

/ One or more NC steady rests

EQUIPMENT:

/ Main spindle for turning and milling spindle operations.

/ Milling spindle for turning, drilling and milling operations

/ A choice of 2 milling spindles with high torque (6,500 rpm / 630 Nm) or high speed (10,000 rpm / 340 Nm)

/ Up to 200 tool stations

/ Additional 3 stations for boring bars and long tools

/ EMCONNECT - digital process analyst (Sinumerik ONE)

HYPERTURN 45

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

HIGHLIGHTS

/ Highly dynamic drives in all axes

/ Two high-performance work spindles

/ Two highly flexible, 12-station tool turrets

/ Stable Y-axis with 70 mm travel

/ State-of-the-art control and drive technology

/ User-friendly dialog control with 3D graphics

/ Compact dimensions

/ Made in the Heart of Europe

EQUIPMENT

/ 2 spindles12-station tool turret

/ Driven tools on both turrets

/ Y axis

/ Automation with EMCO bar or swing loader

/ Siemens or Fanuc control

/ EMCONNECT ? Digital Process Assistant (Siemens 840D sl)

HYPERTURN 45 G3

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

HIGHLIGHTS / Large work area / Highly dynamic drives in all axes / Two powerful work spindles / 12-station/16-station tool turret with impressive milling performance / Stable Y-axis with 80 mm travel / EMCONNECT process assistant for Sinumerik ONE / Fanuc 31ib with 22" multi-touch screen / Compact dimensions / Made in the Heart of Europe EQUIPMENT / 2 spindles / 12-station / 16-station tool turret / Driven tools on both turrets / Y axis with 80 mm travel / Automation with EMCO bar or swing loader / Siemens or Fanuc control / EMCONNECT - Digital Process Assistant (Sinumerik ONE)

HYPERTURN 65

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

HIGHLIGHTS

/ 2 high performance and water cooled spindle motors

/ 2x / 3x 12-times turret with VDI 30 / 40 quickchange system

/ Optional with BMT-turrets and direct drive up to 12 000 rpm

/ 2 / 3 Y-axes for processing of complex turned/milled parts

/ Bar stock feed up to ø 95 mm

/ Optimum chip flow and user-friendly work area

/ Sinumerik ONE or FANUC 31iB according to customers choice

/ Made in the Heart of Europe

EQUIPMENT

/ 2 spindles3 tool turrets

/ Up to 36 driven tools at two or three tool turrets

/ Up to 3 independent Y axes

/ Automation with EMCO bar- or Gantry Loader

/ EMCONNECT - Digital Process Assistant (Sinumerik ONE)

HYPERTURN 65 Powermill

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

HIGHLIGHTS

/ High dynamics thanks to cutting-edge spindle motor technology

/ Maximum thermostability thanks to liquid-cooled spindles

/ High productivity thanks to short tool changing times

/ Both tool systems can be used on both spindles

/ Machine bed construction for maximum stability and vibration absorption

/ Excellent repeatability thanks to linear guides

/ Short setup times thanks to an easily accessible work area

EQUIPMENT

/ Main- and counter spindle, milling spindle, B and Y axis

/ Additional tool turret with milling drive and Y axis

/ 20-, 40-, or 80-slot chain-type tool magazine

/ Tool magazin and control unit ergonomically placed

/ Max. bar stock diameter 65 (76,2 / 95) mm

/ EMCONNECT ? Digital Process Assistant (Sinumerik ONE)

HYPERTURN 95

|

Turning and milling centre

EMCO GmbH

Turning and milling centres

HIGHLIGHTS

/ 2x A2-8" water-cooled main and counter spindles

/ 2x A2-11" powerful main and counter spindle

/ 2x 12-cavity tool turret with VDI 40 quick-change system

/ Optionally with BMT turret and direct drive up to 6000 rpm

/ Y-axes for machining complex turned and milled parts

/ Bar feed up to ø 95/110 mm

/ Optimum chip flow and operator-friendly work area

/ Highest drive and control performance

EQUIPMENT

/ 2 spindlesC-axis for main and counter spindle

/ 2 tool turrets

/ Powerful milling spindle

/ Driven tools on both turrets