EMUGE-FRANKEN

Products

EMUGE-Werk Richard Glimpel GmbH & Co. KG

Chucking systems

Softsynchro® Modular/IKZ

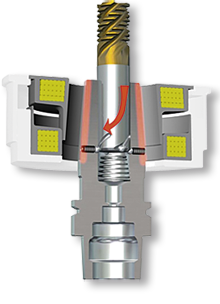

The latest model series Softsynchro® Modular combines the well-proven patented technology of the Softsynchro® minimum length compensation with the required flexibility of tool equipment in modern production. The modular set-up allows the length adjustment of threading tools with male or female centered tool shanks. The HSK shank adaptation to the machine spindle can be adjusted for 1- and 2-channel minimum quantity lubrication systems as well as fluid lubrication. The loss-free transfer of the lubrication medium and the effectiveness of the Softsynchro® technology result in a clear improvement of the thread cutting process and are unique on the tap holder market.

SAFE-LOCK™

|

Chucking system

EMUGE-Werk Richard Glimpel GmbH & Co. KG

Chucking systems

Sophisticated roughing operations in High Performance Cutting (HPC) demand extremely high clamping forces, which usually can only be reached by form closed clamping (e.g. side-lock).

The cause of this pull-out happens due to a micro-creeping motion of the tool inside the chuck, as is the case when using shrink-fit chucks with high cutting-speeds and high pull-out forces.

The combination of spiral-fluted grooves in the tool shank ends, gripped by form closed drive keys inside the chuck and the counter-rotating load on the cutting-edge provides an enhanced fixing of the tool.