ETEL S.A.

Products

ETEL S.A.

Positioning systems

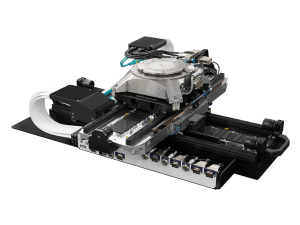

CHARON2 STACKED PLATFORMS

CHARON2 stacked platforms

The CHARON2 platform is built on a robust, reliable and elegantly stacked architecture, designed with modularity and scalability principles in mind. It starts from a standalone X axis to a complete motion system of up to 7 axes; data sheets' performance are available with different electronics configuration. Its compatibility with current and future modules and options allows coverage of the broadest application space and use cases. This flexible, scalable, modular and upgradeable platform offers an entry level to all semiconductor applications and many use cases of other markets, for instance medical, pharmaceutical, material science and others. Continuously evolving in all served markets, CHARON2 supports OEM?s product lifetime extension as well as upgrade paths.

With all-conditions field proven decades of uninterrupted operations and large manufactured volumes of this architecture, CHARON2 represents the most flexible entry point for turn-key motion solutions and sets a new record in price-per-performance ratio. This platform stems from anticipated, aligned, OEM requirements immediately fulfilled with another optimized product, reducing OEM integration costs and time-to-market efforts as well as improving price/performance ratio. The CHARON2 platform represents the broadest available offering in the market.

Its position accuracy of ±1 µm level paired with excellent bidirectional repeatability and high dynamics sustains applications development in all technology and industry fields. From this platform originate standard product configurations, for immediate integration, and customized solutions, accommodating suited performance needs.

CHARON2 remains another perfect example of ETEL vertical integration, based on proprietary IP for motors, electronics and controlling know-how, and synergy with HEIDENHAIN when relating to world-class positioning accuracy feedback.

Characteristics

- Total stroke : up to 650 mm x 410 mm

- Available in 9 standards x 2 electronics = 18 configurations as off-the-shelf products

- Compact footprint

- Payload up to 30 Kg

- Included options and features: rails particle suction (ETEL patent), custom signals, pneumatic lines, and more.

- ISO1 clean room compatibility

- Tip-Tilt correction with the Z3TM combined module

- Built-in vacuum supply at chuck level

- Short move and settle times

CHARON2HD STACKED PLATFORMS

|

Positioning systems

ETEL S.A.

Positioning systems

The CHARON2HD platform is the high dynamic version of the existing CHARON2 family. Using dedicated electronic configurations, all combinations ranging from a simple XY stage to a complete motion system comprising 7 axes are available. CHARON2HD is suited for a broad range of applications and use cases due to its compatibility with all current and future modules and options.

CHARON2HD family members are equipped with larger ironcore motors providing the necessary power to reach a new level of dynamics. The acceleration has been doubled to reach 20 m/s2 while the maximum velocity can reach 2 m/s. Mounting interfaces are the same and allow a drop-in interchangeability with the CHARON2 stacked platform so to provide an upgrade path.

With all-conditions field proven decades of uninterrupted operations and large manufactured volumes of this architecture, CHARON2HD represents the most flexible and high dynamic entry point for turn-key motion solutions and sets a new record in price-per-performance ratio.

Its position accuracy of ±1 µm level paired with excellent bidirectional repeatability and high dynamics sustains applications development in all technology and industry fields.

CHARON2HD remains another perfect example of ETEL vertical integration, based on proprietary IP for motors, electronics and controlling know-how, and synergy with HEIDENHAIN when relating to world-class positioning accuracy feedback.

Characteristics

CHARON2HD family members are equipped with larger ironcore motors providing the necessary power to reach a new level of dynamics. The acceleration has been doubled to reach 20 m/s2 while the maximum velocity can reach 2 m/s. Mounting interfaces are the same and allow a drop-in interchangeability with the CHARON2 stacked platform so to provide an upgrade path.

With all-conditions field proven decades of uninterrupted operations and large manufactured volumes of this architecture, CHARON2HD represents the most flexible and high dynamic entry point for turn-key motion solutions and sets a new record in price-per-performance ratio.

Its position accuracy of ±1 µm level paired with excellent bidirectional repeatability and high dynamics sustains applications development in all technology and industry fields.

CHARON2HD remains another perfect example of ETEL vertical integration, based on proprietary IP for motors, electronics and controlling know-how, and synergy with HEIDENHAIN when relating to world-class positioning accuracy feedback.

Characteristics

- Total stroke : up to 475 mm x 410 mm

- Compact footprint

- Payload up to 30 Kg

- Included options and features: rails particle suction, custom signals, pneumatic lines, and more.

- ISO2 clean room compatibility

- Tip-Tilt correction with the Z3TM+ combined module

- Built-in vacuum supply at chuck level

- Short move and settle times

TELICA DUAL GANTRY MOTION SYSTEM

|

Positioning system

ETEL S.A.

Positioning systems

TELICA is a multi-axes platform primarily dedicated to semiconductor back-end applications. Its dual gantry architecture provides motion along 3 degrees of freedom, X, Y and Z, for a total number of 8 controlled axes. It is designed to fulfill the most challenging requirements of advanced die bonding processes (Flip-chip, Fan-out, 3D stacked packages), µ-LED bonding, dispensing applications and more.

By design, conventional motion system architectures are EITHER optimized for high positioning accuracy OR high throughput. Thanks to a very innovative motion system architecture, TELICA meets BOTH SIMULTANEOUSLY with ±1 µm global placement accuracy (blind move) at a throughput of 10 kUPH for a typical flip chip die bonding application and up to 180 kUPH for µ-LED bonding.

TELICA dual gantry motion system

TELICA is available in two standard variants: variant 1 for Wafer Level Packages (WLP) with X410 x Y445 x Z30 mm travels and variant 2 for Panel Level Packages (PLP) with X750 x Y800 x Z30 mm travels.

TELICA introduces a new metrology approach drastically reducing the Abbé errors as well as the relative positioning mismatch between process tool and substrate. Multi-dimensional encoders ensure the high placement accuracy while water cooled ironcore motors allow extreme duty cycles.

Coupled with ETEL's state-of-the-art AccurET controllers, the TELICA platform benefits from multiple control features such as: zero settling time, non-linear control, advanced feedforward and trajectory filters, full synchronization of all axes with nanosecond jitter, a specific gantry control algorithm, multidimensional mapping, advanced triggering capabilities based on real mapped position, advanced software diagnostic and system identification tools for control optimization.

Main specifications

±350 nm local placement accuracy (moves with local alignment)

±1 µm global placement accuracy (blind moves)

VULCANO2 STACKED PLATFORMS

|

Positioning system

ETEL S.A.

Positioning systems

VULCANO2 is a gantry stacked-axes architecture based on mechanical bearing coupled to high-end optical encoders. Use of ETEL renowned iron-core motors, along with innovative design principles, allows reaching high dynamics at much improved geometrical and motion performance levels.

With focus on easing semiconductor applications, the platform remains a match to all diverse markets and needs requiring solutions for higher dynamics; in fact even its best in class footprint excels to maximize its overall Cost of Ownership value proposition. Customers, aiming to reach higher throughput, duty cycles or to serve heavier payloads with no loss of repeatability or of accuracy, can confidently adopt a standard VULCANO2 or a derived customized solution.

VULCANO2 represents also a perfect solution to all use cases where dynamics, duty cycles and payloads are not so stringent, though positioning accuracy must be established for very long times: delivering several hours of u-level navigation accuracy is no longer a dream but a solid reality from this new offering from ETEL.

The use of this platform is suitable for, but not limited to:

- Wafer Process Control applications such as Overlay Metrology, Critical

- Dimension and Thin film Metrology

- Back-end: flip-chip processes made on large panels/substrates

Characteristics

- Compact footprint

- Payload up to 80 kg

- Nanometer level position stability

- High dynamics

- Excellent bidirectional repeatability and position stability

- ISO 2 clean room compatibility

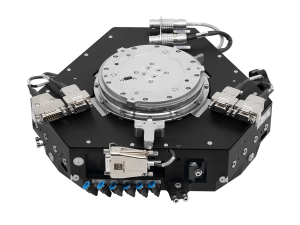

Z3TM COMBINED MODULE

|

Positioning system

ETEL S.A.

Positioning systems

The Z3TM is enlarging the portfolio of modules serving motion platforms. This module adds four independent degrees of freedom, namely along one rotary, one vertical and two oblique axes. By design, this optional module enables complete fulfillment of wafer motion profiles for advanced semiconductor applications, thus providing OEMs with a turn-key solution for any semiconductor technology. The product compactness establishes record density in terms of number of functions per volume, while its performance set new market standards for wafer level accuracies and dynamics.

The Z3TM allows OEMs? migration from expensive and obsolete piezoelectric solutions, eliminating their hysteresis problems while supporting nanometer level resolution, accuracy and repeatability, at even higher dynamics. With embedded support to proper sample alignment, the module then allows further control of wafers planarity, with respect to equipment heads, by means of its additional ?tip? and ?tilt? axes. Such unique functionality enables users with a next-level of process controls, for instance planarity, nominal Angle Of Incidence (AOI), focal plane straightness and many more, all of which result in unparalleled opportunity to yield wafer-level performance by the OEM technique. Today adopters not only simplify their design efforts for higher precision, moreover materialize dramatic reductions in equipment complexity, reliability, integration efforts and overall cost, thus enabling much faster time-to-market at improved price-per-performance ratios.

The Z3TM addition stems from ETEL continuous innovation and vertical integration, based on proprietary IP for motors, electronics and controlling know-how, and synergy with HEIDENHAIN when relating to world-class positioning accuracy feedback.

Characteristics

- Infinite Theta rotation

- Tip and tilt correction over ±0.08° for leveling and for move and settle improvement

- Vacuum feed-through to the chuck level

- ISO class 2 clean room compatibility

- Radial runout of ±3.5 µm

Z3TM+ COMBINED MODULE

|

Positioning systems

ETEL S.A.

Positioning systems

The Z3TM+ is enlarging the portfolio of modules serving motion platforms. This module adds four independent degrees of freedom, namely Tip, Tilt, Theta and Z axes embedded inside an enlarged theta hollow shaft. One configuration includes a Z axis that now features a double stacked Z axis; one fine (FZ) and one coarse (CZ). By design, this optional module enables complete fulfillment of wafer motion profiles for advanced semiconductor applications, thus providing OEMs with a turn-key solution for any semiconductor technology. The product compactness establishes record density in terms of number of functions per volume, while its performance set new market standards for wafer level accuracies and dynamics.

The Z3TM+ flexures based fine Z axis allows OEMs’ migration from expensive and obsolete piezoelectric solutions, eliminating their hysteresis problems while supporting nanometer level resolution, accuracy and repeatability, at even higher dynamics. With embedded support to proper sample alignment, the module then allows further control of wafers planarity, with respect to equipment heads, by means of its additional “tip” and “tilt” axes. Such unique functionality enables users with a next-level of process controls, for instance planarity, nominal Angle Of Incidence (AOI), focal plane straightness and many more, all of which result in unparalleled opportunity to yield wafer-level performance by the OEM technique. Today adopters not only simplify their design efforts for higher precision, moreover materialize dramatic reductions in equipment complexity, reliability, integration efforts and overall cost, thus enabling much faster time-to-market at improved price-per-performance ratios.

The Z3TM+ addition stems from ETEL continuous innovation and vertical integration, based on proprietary IP for motors, electronics and controlling know-how, and synergy with HEIDENHAIN when relating to world-class positioning accuracy feedback.

The Z3TM+ flexures based fine Z axis allows OEMs’ migration from expensive and obsolete piezoelectric solutions, eliminating their hysteresis problems while supporting nanometer level resolution, accuracy and repeatability, at even higher dynamics. With embedded support to proper sample alignment, the module then allows further control of wafers planarity, with respect to equipment heads, by means of its additional “tip” and “tilt” axes. Such unique functionality enables users with a next-level of process controls, for instance planarity, nominal Angle Of Incidence (AOI), focal plane straightness and many more, all of which result in unparalleled opportunity to yield wafer-level performance by the OEM technique. Today adopters not only simplify their design efforts for higher precision, moreover materialize dramatic reductions in equipment complexity, reliability, integration efforts and overall cost, thus enabling much faster time-to-market at improved price-per-performance ratios.

The Z3TM+ addition stems from ETEL continuous innovation and vertical integration, based on proprietary IP for motors, electronics and controlling know-how, and synergy with HEIDENHAIN when relating to world-class positioning accuracy feedback.

METIS PLANAR PLATFORM

|

Motion Systems

ETEL S.A.

Positioning systems

This platform, Metis, is a hybrid planar mechanical/air bearing platform dedicated to step and scan applications. It is a 6 axes platform moving in X, Y, Z and Theta directions. Dynamic flatness over the full travel as well as bidirectional repeatability are key parameters. This platform is currently used in:

- Wafer Process Control applications such as Critical Dimension and Thin film Metrology.

- Wafer scribing

- Wafer Laser Thermal Annealing

It might also be used in Back End Of Line Lithography machines (mask aligners) and in some wafer dicing application.

This platform features:

- Flatness of motion given by the air bearing

- Unlimited rotation in Theta

- Double Z integration: Coarse travel for loading/unloading and fine travel for focus adjustement

- Buit-in gravity compensator in Z (patent pending)

- Yaw correction can be done by slightly shifting the Y1 and Y2 motors

- Can be further integrated with an Active Isolation System fully controlled by ETEL

- Travels in X and Y can be made longer with some limitations on the performance

Main specifications

- Total stroke: 320 mm for XY x 12 mm for Z

- Speed: 1.2 m/s for XY, 0.1 m/s for Z and 15.7 rad/s for T

- Acceleration: 1.2 g for XY, 0.2 g for Z and 104.7 rad/s2 for T

- Position stability: ±25 nm for XY, ±15 nm for Z and ±0.2 arcsec for T

- Bidirectional repeatability: ±0.4 µm for XY, ±0.3 µm for Z and ±2 arcsec for T

Ask for the corresponding Integration Manual for more information.

VULCANO XY STACKED PLATFORM

|

Positioning system

ETEL S.A.

Positioning systems

The Vulcano XY system is a three-piece-design allowing a compact and cost engineered solution, coupled to mechanical bearings and high-end optical encoders.

The baseplate of the bottom axes (Y1 & Y2) is composed of 2 ironcore linear motors, controlled in a gantry mode, when used with AccurET controllers, to allow better repeatability and optimal control efficiency. The upper axis (X) is composed of a single ironcore linear motor. The use of ironcore technology offers a high force density resulting in high acceleration and speed while keeping the operating temperature at a rather low level.

The baseplate of the upper axis (X), which also holds the motor of the bottom axes (Y1 & Y2) is made of aluminum for mass optimization and dynamics. Thermal expansion is handle by flexure elements.

There are 3 linear guides on the bottom plate. The two external linear guides laying on the bottom plate of VULCANO are recirculating ball bearings while the internal one (located in the middle of the baseplate) is composed of a recirculating roller bearing. The decoupling between the three guides is made through flexural elements. Some of these elements attached to the bearing blocks of the external guides allow a translation in the X direction. Some others attached to the central rail allow a rotation around the vertical direction.

The upper axis (X) integrates 2 linear bearings. The decoupling is made via another set of flexural elements allowing a translation in the Y direction for one of the rail.

The use of this platform is suitable for, but not limited to:

- Wafer Process Control applications such as Overlay Metrology, Critical Dimension and Thin film Metrology

- Back-end: specific flip-chip processes made on large panels/substrates

Characteristics

- Compact footprint

- Nanometer position stability

- Short move and settle times

- High dynamics

- High bidirectional repeatability

- High position stability

- ISO class 1 clean room compatibility

Ask for the corresponding Integration Manual for more information.

VULCANO XYT STACKED PLATFORM

|

Positioning system

ETEL S.A.

Positioning systems

The Vulcano XYT platform is made up of the standard Vulcano XY outfitted with the RTTB rotary module which includes high resolution encoder coupled to an outstanding mechanical bearing.

The use of this platform is suitable for, but not limited to:

-Wafer Process Control applications such as Overlay Metrology, Critical Dimension and Thin film Metrology

- Back-end: specific flip-chip processes made on large panels/substrates

Characteristics

- Compact footprint

- Nanometer position stability

- Short move and settle times

- High dynamics

- High bidirectional repeatability

- High position stability

- ISO class 1 clean room compatibility

Ask for the corresponding Integration Manual for more information.

VULCANO XYZ3TH STACKED PLATFORM

|

Positioning system

ETEL S.A.

Positioning systems

The Vulcano XYZ3TH platform is made up of the standard Vulcano XY outfitted with the Z3TH combined module. This 4 degrees of freedom module, provides 364° Theta rotation, double Z-axes, a coarse one for wafer loading and unloading, and a fine one for focus adjustment, as well as a Tip and Tilt correction over ±0.1°.

Characteristics

- Compact footprint

- Nanometer position stability

- High dynamics: 2.5 g, 1.5 m/s

- Low move and settle times

- ISO1 clean room compatible

- Tip-Tilt correction over ±0.1°

- Double Z integration

- Built-in gravity compensator in Z

- Outstanding Z straightness

- Enhanced Z repeatability and jitter

- Ability to correct stage flatness

- Built-in vacuum supply at chuck level

Ask for the corresponding Integration Manual for more information.

Z3TH COMBINED MODULE

|

Combined Module

ETEL S.A.

Positioning systems

The Z3TH Combined Module is enlarging the scope of modules that can sit on top of the existing XY platforms. The Z3TH, 4 degrees of freedom module, provides 364° Theta rotation, double Z-axes, a coarse one for wafer loading and unloading, and a fine one for focus adjustment, as well as a Tip and Tilt correction over ±0.1°. This Z3TH module is a nice alternative to piezo based Z actuators, eliminating the hysteresis and non-linearity in open loop while offering better tracking error during movement, repeatability, and move and settle performance yet over much longer travels.

The Z3TH module is primarily dedicated to front-end type of applications and provides a right solution to cope with any applications requiring:

- Alignment between a process tool and a substrate

- Mapping of flatness

- Move and settle improvement

First applications are related to back-end lithography and wafer process control.

Characteristics

- 364° Theta rotation

- Tip and tilt correction over ±0.1° for leveling and for move and settle improvement

- Vacuum feed-through to the chuck level

- Double Z integration: coarse travel for loading/unloading and fine travel for focus adjustment

- ISO class 1 clean room compatibility

- Low radial axial and radial runout of ±1 µm

Ask for the corresponding Integration Manual for more information.

ZT COMBINED MODULE

|

Combined module

ETEL S.A.

Positioning systems

The ZT box is a module combining two degrees of freedom, in Z and Theta, within one single unit. Two actuations are possible along the Z direction, a coarse one and a fine one. This module can be used in a standalone mode or mounted on top of an XY platform. This module is especially well suited for wafer process control applications such as thin film metrology, critical dimensions, etc.

Characteristics

- Infinite rotation

- Built-in vacuum supply at wafer chuck level

- Built-in gravity compensator

- ISO1 clean room compatible thanks to vacuum suction

- Coarse Z axis with 12 mm stroke for wafer loading/unloading and fine Z with 4 mm stroke for focus adjustment

- Version without a coarse Z can be done

- Very good Z jitter as well as move and settle

Main specifications

- Bidirectional repeatability: ±0.3 µm for Z and ±2 arcsec for T

- Position accuracy: ±0.6 µm for Z and ±3 arcsec for T

- Speed up to: 0.1 m/s for Z and 15.7 rad/s for T

- Acceleration up to: 0.2 g for Z and 104.7 rad/s² for T

- Position stability: ±5 nm for Z and ±0.2 arcsec for T

- Load capacity: 1 kg

Ask for the corresponding Integration Manual for more information.