Hi All

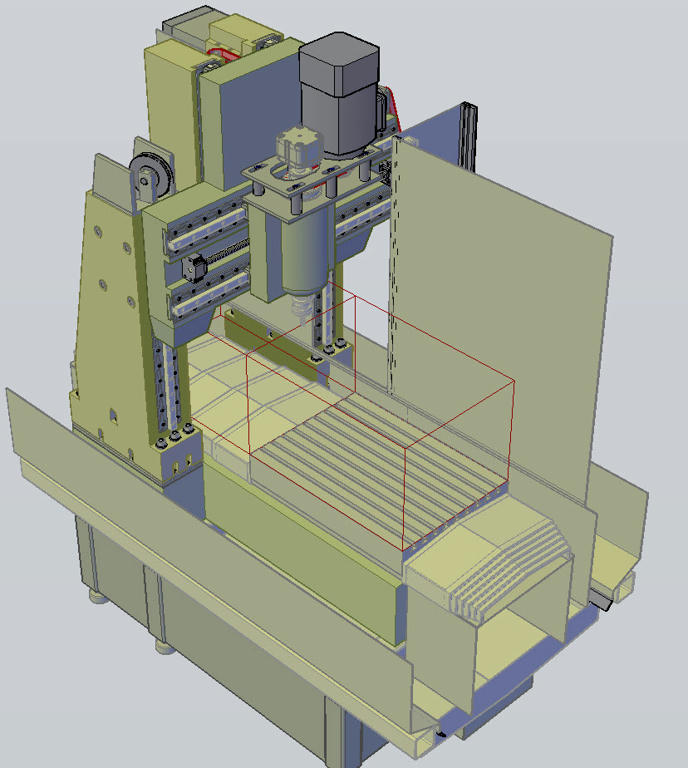

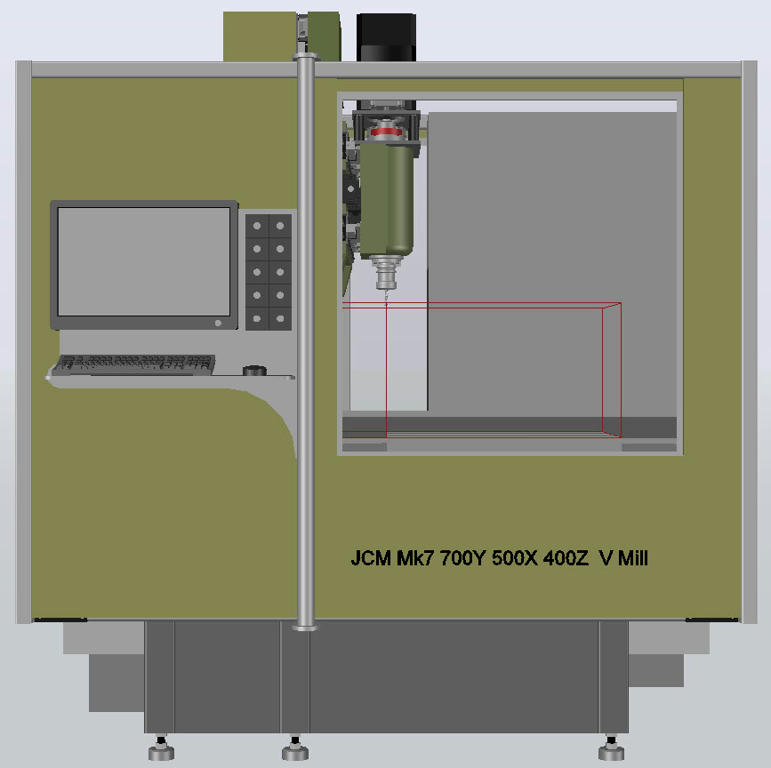

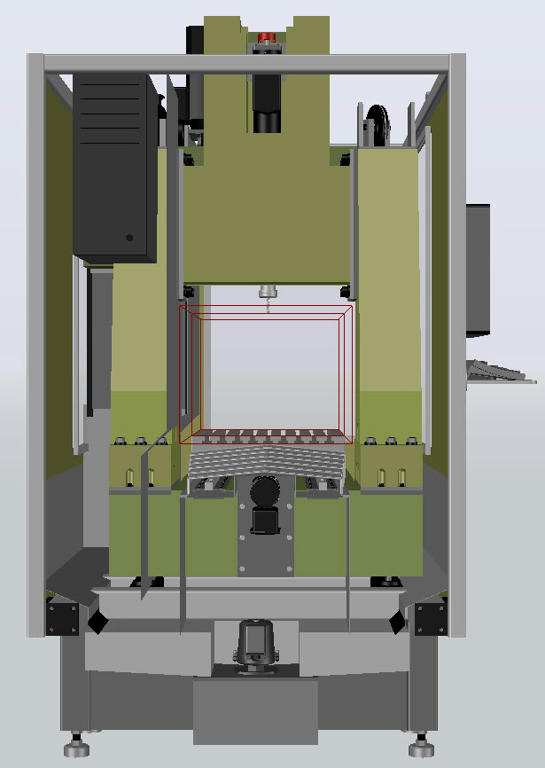

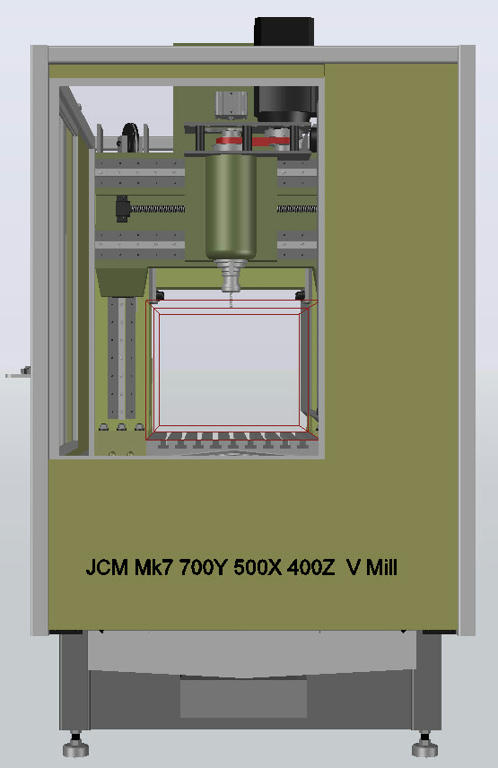

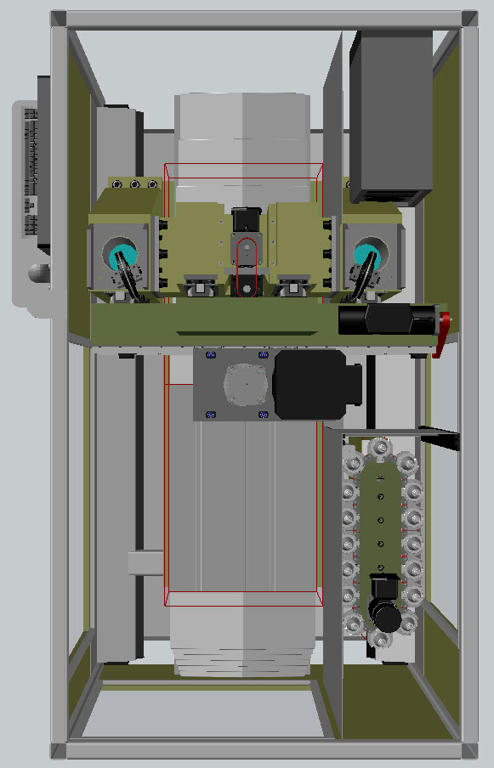

Here is the latest Version Of the Epoxy Mill Version 7

I posted the first version 1 here Last year:

http://www.cnczone.com/forums/epoxy_...ill_500_a.html

This year I posted this:

http://www.cnczone.com/forums/epoxy_...0x500x400.html

However there have been significant Design changes I therefore started this new thread.

Now version 7 There is a full set of 3D Autocad drawings; about 123 files, all referenced correctly into a main file and some notes posted in a public directory here:

The Entire file set 13mb is posted at the link below:

Free File Sharing Made Simple - MediaFire

I have not pasted the notes into this post as they are rather long.

They can be found here: (Please read the notes before posting a reply.)

Notes Only:

http://www.mediafire.com/file/sggxfo...Notes Mk 7.doc

There is still more work to be done....as always.

Cheers

John

A few images below:

Results 1 to 7 of 7

-

02-09-2012, 08:22 AM #1

Junior Member

Junior Member

- Join Date

- May 2007

- Posts

- 68

Epoxy Concrete CNC V Mill 500x700x400H Designed in CAD and method

-

02-09-2012, 01:31 PM #2

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

Looks like you have put a lot of work into that John!

-

02-21-2012, 02:36 PM #3

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 23

Impressive design work

Hi John,

I have followed your design threds and E/G test. Good work.

Looking forward to follow this build. Especially how to cast E/G for a base this size and how your are going to mount gantry and guides.

Best regards

Jacob

-

02-22-2012, 03:33 AM #4

Registered

Registered

- Join Date

- May 2003

- Posts

- 162

A LOT more work to build it than draw it

-

02-22-2012, 03:59 AM #5

Junior Member

Junior Member

- Join Date

- May 2007

- Posts

- 68

Hi All

Yes and drawing it is no easy job either, Pushing 450+ hours of design time now. You think you have it and then a little gotcha pops up. Like the interference between tools and the tool changer support....fixing that now the swarf and coolant management sheet metal is next. Also the enclosure frame needs to be refined past simple stick work, And a hundred other little tweaks.

Where are all the ACAD users in the forum? ...Not many downloads from Mediafire. If you don't have AutoCAD you can download a free viewer.

Autodesk also offer free student versions if there are students watching. Even if you do not wish to build the machine the files give a good example of working with linked files and how it simplifies complicated mechanisms. The main file in this set is named Underscore Main _Main..... in the file set. note there is almost no actual drawn objects in the main file if you right click an object you can open its file as a "child" of the main. And child files can have children in them, and so on.

I spent the last couple of weeks clearing a space in the workshop for it...Another not easy job; gee it is hard to throw out "Handy" stuff LOL.

Anyway with a bit more pushing and shoving that will be finished.

The Steel base frame will be the first part constructed, It has to accommodate chips and coolant. I would have liked to incorporate a chip screw conveyor, Decided not to after I found out what they cost. So it has a simple pull out drawer/tray Its pretty big so it will not require cleaning out very often.

I have also arranged with a friend to use his sliding table saw for the formwork A nice German made Altendorf. That will speed up that process.

Next step will be the base casting.

Its taken a bit longer to get ready for the pour but it is getting near...I will keep you guys posted.

Cheers

John

-

02-22-2012, 03:55 PM #6

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

From a design perspective have you allowed clearance for things like air blower flex nozzles, coolant delivery nozzles, and associated flex tubes to the head and even things like valveblocks etc?

I assume you have allowed for unlimited length stock going through the throat of the machine?

-

02-22-2012, 10:09 PM #7

Junior Member

Junior Member

- Join Date

- May 2007

- Posts

- 68

Hi Roman Lini

Working through those at the moment, I plan to use energy chains for the power side, air and coolant as well. The Z axis is no problem. just an inverted U chain, The table X axis (The long travel in this design the "Front" is to be the side of the machine) Is driven from a fixed drive on the base so no problem.

I do however want to fit the table with a 4th axis Ideally I would like to fit a small energy chain under it along the bed and under the splash guards to provide power and air to that. Its a bit tight for space.

The Y axis chain will sit along the top of the z axis carriage.

There is ample room for all the control gear to be fitted behind dividing wall that on one end protects the tool changer from chips and coolant. Note the air operated vertical sliding door that opens, allowing the tool magazine to slide forward and present a tool to the spindle. The supporting column is getting a redesign.

I have roughly placed a PC Case in position as seen in the drawings there is plenty of spare space for the control gear to be properly housed.

Unlimited length of work has not been given a high priority, it can be done by removing the windows at each end. maybe I should make that easier. There is not enough room to slide them away unless they are split in two. Its pretty rare on my manual mill that I work on long material. Do you think I should split the windows at the expense of visibility or just leave them removable?

Cheers

John

Similar Threads

-

Epoxy Granite In Practice (Mineral Casting, Polymer Concrete)

By johnohara in forum Epoxy GraniteReplies: 71Last Post: 08-25-2020, 01:18 PM -

Epoxy Concrete CNC mill 700x500x400 Design and Build

By JohnMcNamara in forum Epoxy GraniteReplies: 7Last Post: 01-25-2012, 07:34 PM -

Epoxy Concrete Commercially Made Machines only

By JohnMcNamara in forum Epoxy GraniteReplies: 5Last Post: 05-31-2011, 03:05 PM -

Epoxy Concrete Aggregate Ratio Mixing Method

By JohnMcNamara in forum Epoxy GraniteReplies: 6Last Post: 05-12-2011, 01:52 PM -

Epoxy concrete CNC mill 500 X 500 X 320h work area concept drawings

By JohnMcNamara in forum Epoxy GraniteReplies: 10Last Post: 04-30-2011, 07:09 AM

Reply With Quote

Reply With Quote