Well, I got bored doing production in my little shop, so I decided its time for a little fun

For starters, I have acquired two chunks of 303 Stainless! They are 5" dia and 3 1/4" long! So I setup my little horizontal band saw, and cut the bar stock into cubes around 3 1/8 x 3 1/8 x 3 1/8. Then I used my face mill to rough them down to around 3.010" cubed. Lastly, I put new carbide inserts into my face mill, and took one final pass on all six sides leaving a nice smooth, flat, parallel, perpendicular, and square cube! Then I drilled a 1/2" hole to the center o the cubes from all six sides.

Widgit

Results 1 to 20 of 107

-

02-18-2008, 01:15 AM #1

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

Making Large "Turner's Cubes" on an Engine Lathe

-

02-18-2008, 01:26 AM #2

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

Now I need to make a fixture plate that mounts on my lathe's spindle, to do that I will use the back plate with D1-4 cam lock studs from my 3-jaw chuck!

I found a nice block of aluminum in my scrap pile, and machined one surface flat and counter-bored it to fit snuggly on the backplate. Then I transferred the three holes from the backplate to the aluminum block, and drilled & tapped them for 1/4-20 UNC around 3/4" deep.

After fastening the block to the faceplate and to the lathe's spindle, I turned the OD and face true. Then I removed the block from the faceplate, and put it in my Mill's vise, I had to remove one of the jaws to get it to fit!

Then with a 1/2" 2-flute end mill, I machined a square pocket in the center of the block around 1/8" deep. In order for the cubes to fit in this nest, I had to go and extra 1/4" past each corner with the end mill.

Now the cubes fit snuggly in the center of the block!

Widgit

-

02-18-2008, 01:34 AM #3

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

Then with a drill chuck, I drilled 4 holes in the block and tapped them for 1/4-20 UNC around 3/4" deep. Now I need to make some custom straps to hold the cube on the corners where it will be strongest as I remove material with the lathe.

The clamps are 1"x1"x3" aluminum, with a .290 dia hole down the center of the long side. Next I milled a step in the end and in the side of each clamp, so it will hook on to the cubes!

Widgit

-

02-18-2008, 01:39 AM #4

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

It's been a good day, I have made the fixture and its clamps, and spent a few hours running the lathe! So far I have finished 3 of 6 sides in one of the cubes!

I can't wait to finish these, as I have always wanted to make one for myself! They look so cool!

Tomorrow I will finish up the lathe work, and spend a day deburring and polishing!

Widgit

-

02-18-2008, 01:44 AM #5

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

FUN????? Your idea of fun is one h*** of a lot of work. But I guess you are correct, it is fun when you don't have to do it and are just doing it for the satisfaction of making something neat.

Some day I plan on making one but I think I will cheat in my lazy old age and program a CNC to do it.An open mind is a virtue...so long as all the common sense has not leaked out.

-

02-18-2008, 02:39 AM #6

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Something strangely hypnotic about those cubes. Even one that's spoiled. I have one I started but spoiled a while back. I should get going on another.

Do you plan on making 2, or is the extra cube for insurance?

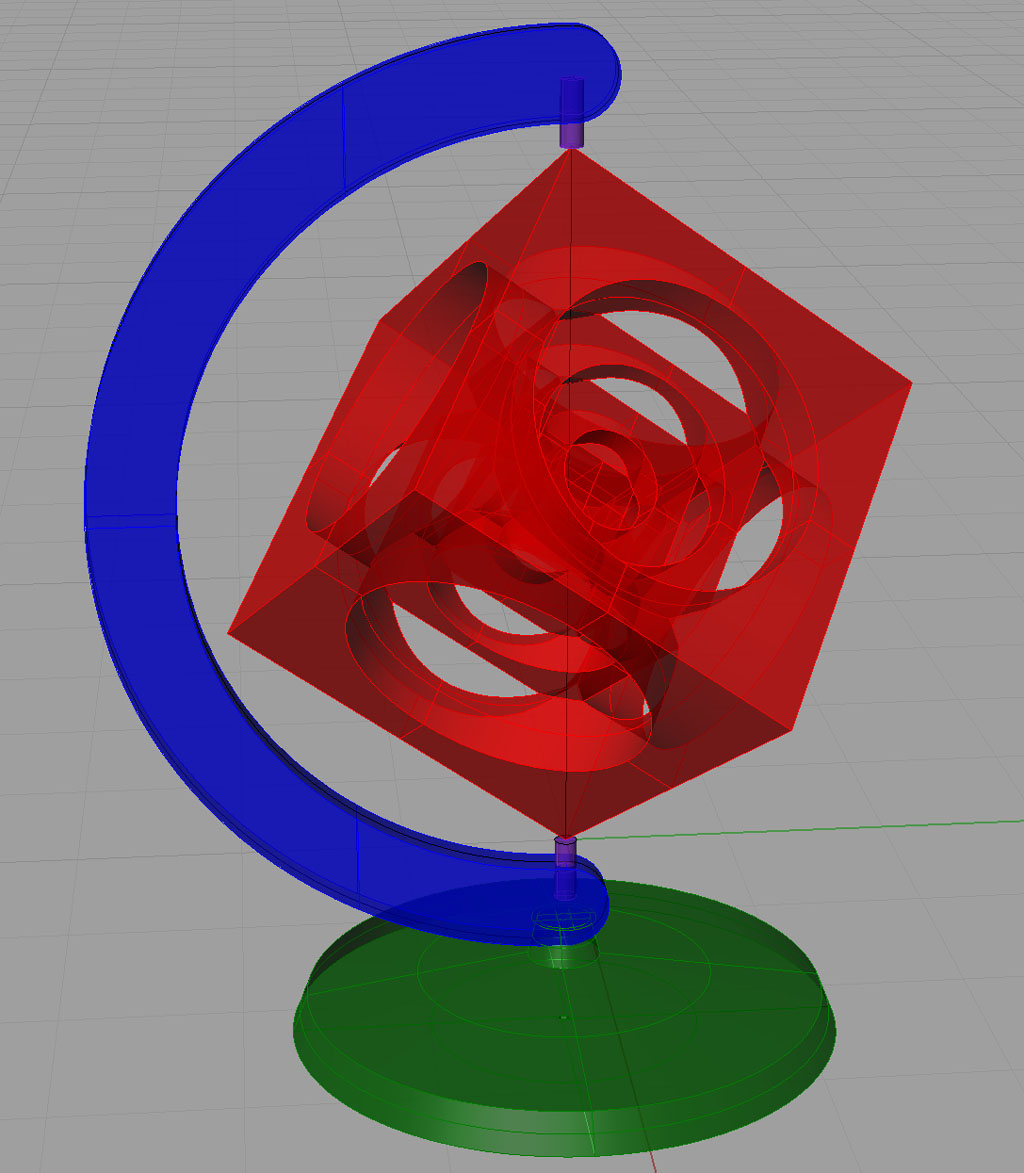

They're even fun to draw in a CAD program:

Geof, if you're going to cheat with CNC, you need to make a whole series with different things inside. Perhaps one for each suit of cards or some such:

I've seen some odd things come out of lathes:

Cheers,

BW

-

02-18-2008, 02:52 AM #7

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

The day I can't put in a good day's work, is the day I'll start worrying!

I like to work, and I wanted to show a good solid procedure for holding a delicate stainless part in the lathe! I'm sure there ares dozens of ways to make these including CNC, but I wanted a truly perfect one or two if possible!

Nice cubes Bob! I'll have to experiment with my CAD program to see if I can make some of them!

Widgit

-

02-18-2008, 08:20 PM #8

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

One is finished & deburred!

It was a lot of work, but well worth the effort!

Widgitwww.widgitmaster.com

It's not what you take away, it's what you are left with that counts!

-

02-18-2008, 09:55 PM #9

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

That's a beauty!

You've a good eye for proportion on that one.

Widgit, what are your preferences for boring bars? I'm curious about this project, but also for your mill's boring head.

Best,

BW

-

02-18-2008, 11:08 PM #10

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

-

02-19-2008, 01:00 AM #11

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 91

Excellent Work!!!

-

02-19-2008, 02:19 AM #12

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1136

Eric, those look great, bet you could sell them.

I'd always thought a turners cube, as the English apprentices were taught, had undercuts so that the cubes separated, cube inside a cube that can't come out. Lautard in one of his books walks through how. here's a three cube one i made years ago, its 1" sq. Lot of fun just having it sit on the desk because all the non technical people would pick it up and hurt their brains trying to figure it out. lol. its the machinist's equivalent of worry beads so the edges have long since been rounded.

http://i20.photobucket.com/albums/b2...urnerscube.jpg

-

02-19-2008, 04:18 AM #13

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

Very nice job Eric.

But I think it is toss up between the finished cube and the elegant fixturing you built to machine it; both are an impressive example of craftsmanship.An open mind is a virtue...so long as all the common sense has not leaked out.

-

02-19-2008, 04:26 AM #14

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

-

02-19-2008, 06:27 AM #15

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

Plastic!!! Cast Acrylic.

Make them in cast acrylic, polish all the surfaces optically clear and they would look fantastic. Especially if you illuminated them correctly, you would get a prismatic effect in all directions.

See if you can locate a supplier for blocks of cast acrylic and how much it would cost, I will cover the material cost if it is not too horrendous in exchange for you making me one.

P.S. Never, ever toss a fixture in the scrap...that guarantees you will need it the day after you tossed it.An open mind is a virtue...so long as all the common sense has not leaked out.

-

02-19-2008, 11:38 PM #16

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

-

02-21-2008, 01:52 AM #17

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

Ok, I'm totally hooked on this large Cube, especially when its spinning on it's axis!

Unfortunately, my abilities in 3D CAD are nonexistent!

Could some one please tell me what the compound angle is if the cube is rotated 45°, then rotated until the two furthest points are perpendicular!

(The cube measures 3"x3"x3")

I have found some solid Vee Jewel Sapphire Bearings and points, and plan to make a base with a support arm that will allow the cube to rotate like a globe!

http://www.smallparts.com/products/d...ns/vja-hst.cfm

But in order to install the Sapphire Bearings, I need to position the cube with its point upward.

Widgitwww.widgitmaster.com

It's not what you take away, it's what you are left with that counts!

-

02-21-2008, 02:33 AM #18

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 120

Hi Mr. Widgit,

I'm not sure which compound angle you are referring to; but the diagonal distance across the face of a cube is Square root of 2 times the length of the side, and the the diagonal distance from the most opposite vertices is Square root of 3 times the length of the side.

In your case the distance between the mounting points ( assuming no radius) is 1.732 x 3 inches = 5.196 inches.

hope this helps.

regards Garyembrace enthusiasm to accomplish the task

Gary Davies... www.durhamrobotics.com

-

02-21-2008, 02:40 AM #19

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

-

02-21-2008, 03:07 AM #20

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Widgit, sorry, while I was drawing this you were explaining what you really wanted.

I literally have to run out the door, but I'll pull the compound angle when I get back if nobody else has posted.

Sorry!

BW

Similar Threads

-

Hawk150-Acramatic2100 "NC Engine Failed"

By espinja in forum Cincinnati CNCReplies: 13Last Post: 12-16-2022, 10:05 PM -

X Axis "Goes Off Pattern", "Awry", "Skewed", "Travels"

By DaDaDaddio in forum Laser Engraving / Cutting Machine General TopicsReplies: 1Last Post: 05-06-2013, 09:59 AM -

RFQ : 5/8" cubes (6061 alum.) 100/1000/5000 pcs

By dukejavelin in forum North America RFQ'sReplies: 12Last Post: 03-08-2013, 03:04 AM -

What is this called a "internal side crank engine" ?

By Andy-7300 in forum I.C. EnginesReplies: 2Last Post: 07-12-2008, 07:04 PM -

"Fixing" bent engine valve?

By mmmjboner in forum Bending, Forging, Extrusion...Replies: 18Last Post: 07-16-2007, 09:40 PM

Reply With Quote

Reply With Quote