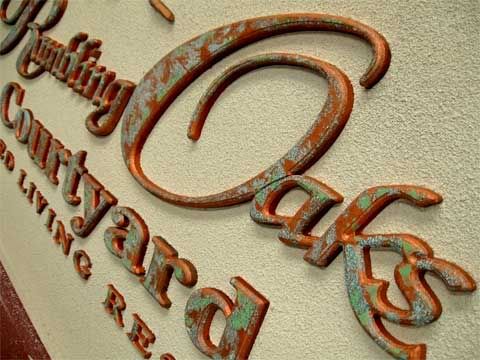

For years I've been surfacing my letters and background with the Sculpt Nouveau metalic paints in order to get away from paint. It also gives me opportunity to add some textures. These are some letters for a housing development "Cantebury" I suggested to the developers it might look nice to have copper letters which have been aged. I was able to increase the price with this technique.

The process is to paint one of their metalic paints and follow up with a acid, which starts the oxidizing process.

Here are some samples.

If anyone is interested, they can look up the products at www.sculptnouveau.com The products I've had the most experience with are the "B" solutions (Copper, Brass, Bronze, and Iron.) Iron and Copper are my favorites. You'll also need one of their acids, Patina's, which starts the oxidation process. One friendly, neat things is, if you aren't pleased with what you've done, no problem, just paint another coat, mist on a little more patina and away your go..

Joe Crumley

www.normansignco.com

Thread: Sculpt Nouveau

Results 1 to 20 of 32

-

03-09-2010, 04:56 AM #1

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Sculpt Nouveau

-

03-11-2010, 05:46 AM #2

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 272

As always nice work Joe. I have been admiring your work.

Here is something I have been using due to local vendors and products in stock.

http://www.modernmastersinc.com/prod...ors.aspx?pl=ME

-

03-11-2010, 11:08 AM #3

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Sculpt Nouveau

I'm also a big fan of some of M&M's paints but it's a poor substitute, when it comes to the oxidization porcess. I've been unable to get any help, of any kind from M&M, not even color charts. I've boutht their Iron and Copper both of which turned solid in the bottle before I could use much of it.

I am very fond of their metalic paints that aren't for oxidizing however. If they would only provide color samples.

Perhaps you could find their rep and get some help, I couldn't.

-

03-12-2010, 02:15 AM #4

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 272

Local Sherwin Williams carry M&M they have been big help and Kelly Moore if I am not mistaken.

I went to MM website and found local distributor with my zip.

My uncle is old time Copper Smith with alot of historical work in his portofolio from europe so he was a big help as well.

-

03-12-2010, 02:30 AM #5

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Sculpt Nouveau

Good for you.

We also have several M&M dealers.

I'd suggest you begin by buying a small container of Iron and their oxidizating soluton. Once you open it up, watch out, the whole bottle will turn solid in a week. Have you found any color cards to show customers?

Their non oxidizaing metalic paints are excellent. I really like using them.

The Critter spraygun is my favorite. It costs $39. from Amazon

Please show any test you are running.

-

03-12-2010, 02:44 AM #6

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 272

Tool and fastener sign I posted had M&M rust activated Star right in the center.

Bit of rustic feel to it.

I may have to go to OKC within next couple of weeks I may stop by Norman for cup of coffee at your shop!!!!!

-

03-12-2010, 03:36 AM #7

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Good to have you over.

-

03-25-2010, 01:47 AM #8

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 229

Nice work, Joe!

Did you do the leafy scrolls in the first two photos with a beading bit/cutter, and a cove or a classic bit, and do a perimeter rout, or did you run it as a 3D file?

It looks like there are a couple of tight corners to have to fit in to.

What is the big shaped background piece whick looks like a square with extensions on each side- is it a dibond-type of substrate?

Thanks!

-

03-25-2010, 02:37 AM #9

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Stewey,

The method I used to route the dingbats is very simple. This is a profile Aspire 3D. I used a 1/4" ball nose with very little step over. The furrows come about with this technique. If you could see these in real life there is much more detail. I smoothed the high part with sandpaper. It's quiet easy.

The letters and scrolls are attached to DyBond from the back with screws.

-

03-25-2010, 02:54 AM #10

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 229

Thanks Joe- I can see now how the step effect can become a bit of a feature...

and not too slow to do if fairly coarse.

So you didn't use some gorilla-type or a contact glue as well as the screws from the back?

Ian

-

03-25-2010, 09:47 AM #11

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Stewey,

Putting up the letters was a quick two man job. One on front and back. We used silicone glue and screws. The material was Extira, which is exterior fiber board. I'm not sure what you have available over there.

The routing time was rather short and wash't pretty. Although the surface was rough, it was uniformly so. I made a couple of these using 18lb HDU but the didn't have as much character.

Hope this helps.

Joe Crumley

www.normansignco.com

-

03-25-2010, 10:01 AM #12

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 229

Thanks, Joe- I wondered what Extira was.

We have MDF here, but you'd never put it outside. There's no exterior version available here, except perhaps Weathertex, which is a heavy weatherproof masonite type of dark stuff that's only available in 3/8" thick sheets.

Maybe that is its equivalent...

-

04-04-2010, 04:31 PM #13

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Stewey,

I bet that's close to the same material. It's good to keep in mind, if a material is made for exterior use, it may be laced with oil or phenolic resins. Those may be hard to coat out with water based paints such as latexes. You will need to prime with a shellac based primer like Kils. I usually scrub the surface with a little soapy water and stiff brush.

Perhaps you will have some siding materials available. They come in 1/2" thickness.

Good Luck,

Joe Crumley

www.normansignco.com

-

04-06-2010, 12:14 AM #14

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 229

Thanks, Joe.

After I read your reply, I looked Extira up on the 'net, and then looked Weathertex up- and our weathertex is made without glues- it uses a super heat and pressure to fuse the hardwood fibres. I thought that was interesting.

The stuff is hard and heavy, but it lasts well in the weather, and it takes all paints. Still only 3/8" sheet thickness.

Thanks again.

-

04-06-2010, 01:43 AM #15

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Looks like a simular product.

Extira is very heavy but I can't say it's all that hard. I can take a chisel to a corner and get it to flake. The manufacture said it could be painted with all paints. NOT. Since it's waterproof, water based paints do not get a good grip.Prime as per my previous suggestion.

In my shop, I have a large wood burning stove. Extira scraps are excellent for heat. I bet your product is also since it's fused, and hard.

I don't remember what type of CNC your using.

Joe

-

04-06-2010, 02:37 AM #16

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 229

Our router was an Esab Signmate 1000 I think, born in 1990. It had x & y servos & a pneumatic Z axis with screws to set the depth it could go to.

There's a 3 hp Perske spindle, and a 2 metre wide by 16 long ft bed. I haven't got the back end of the bed set up though- it's just set up for 11 ft in length at the moment.

IN 2000 it was retrofitted with the latest Texcel (aussie router) drives, and newer servos & controller etc, and a motorised Z axis, and then the bloke I got it from bought it in 2001. He bought Enroute 3 for it, and later upgraded to pro, but never used the 3D side of it. His buisness changed direction & he bought a new router with auto tool changes & whizz-bang features in 2008, and we bought the 'old' one from him.

That was south of Sydney. It was a 1300 km trip to freight it in pieces up to us, and then the giant learning curve, reassembling it, & getting it going & learning the software, feed speeds, tool details, breaking cutters etc. We bought it in May, got it delivered up in June & assembled it in July '08.

I've burned out one driver & two servos on the Z axis doing lithophanes. We recently got a ballnut & leadscrew from China to try & solve that problem.

Epineh here on these forums helped me diagnose & replace the burned out components on the crook drive/amplifier. That was terrific.

After trying a stack of possible excuses, inconclusively, I put the problem down to the delrin nut on the acme screw of the Z axis. I think that a heap of negligible movement in the one spot eventually caused heating & binding of the nut on the screw and that put the extra load on the servo. Getting a more powerful servo did not fix the problem- burned that out too. Trying to run it in the air above the job with no tool load also did not help, so the problem was not coming from the cutter or the material. I had a big thread here in the servos category of these forums about it overheating.

I haven't yet attached the ballnut lead screw- it only arrived last Thursday.

For ordinary 2D & 2.5D work, the router was fine, and for 3D stuff with say a 2" height range it was fine, but it was just the small stuff that used to cause the binding & excessive loads.

So, it was a bigger learning curve than I'd have ever anticipated....not that I'm complaining...and these forums have been or tremendous benefit with helping to figure out answers!

It's still a Tekcel controller on an Esab bed. I may retrofit it to something better sometime, since Tekcel aren't so good with info on fixing my problems, now that the hardware & circuitry is 10 years old. When it's earned me what it cost, we might upgrade the electronics, and maybe add in Mach3 or something, but at the moment I like the driver software which is proprietory to the machine.

I also don't mind Enroute, now that I have got the hang of it. The LPT dongle is a pain having to remove it to a different PC if I want to work on it at home, but such is life, I guess. I'm not about to buy Aspire, as I don't have any problems with what we have, except for a lack of funds at the moment!

-

04-06-2010, 04:17 AM #17

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Sewey,

You have definantely been put through the baptism of router hell.

I'm not much of a tech fellow so I have little to add except, my router is running on Mach 3 and it's a dream once it gets installed and set up. Cheap too.

My latest router is a 5'X10' EZ. I've had it for three years. It doesn't have a TC or Vac hold down which would be nice to have. I sold off a wobbbly Shopbot and wouldn't recommend that.

My software is ArtCam but would save 6K by adding Aspire. My assisstant has one and it's faster and cleaner than ArtCam.

Our nextdoor neighbors bought an old Thermwood and changed out the controll box and also incorporated Mach 3. Seems to be working well. All in all I don't do much 3D work. It's too slow and clunky. I often find other ways to get my work done. 3D for me has real drawbacks for standard operating. It's been over sold in the sign industry. It main be essential for other applications like jewelry. Don't know.

Good luck with the exterior fiber materials.

Joe

-

04-06-2010, 04:46 AM #18

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 229

Thanks, Joe.

I forgot to mention ours came with a vac. bed, but it had been removed to allow more room under the gantry, and we don't have 3-phase power on tap here. We have a 20 kva diesel gen-set, and it wasn't worth cranking that up all the time. I ended up buying a small rotary phase converter so we can run the spindle from single phase power- much more peaceful! I have a manually adjustable frequency/speed controller on the wall beside the router.

I just use timber screws and chocks and whatever else seems necessary to hold the substrate onto the bed for routing. Vacuum would be nice, but we have a 10 hp vac. motor to have to power, and currently don't have the needs for it, considering the cost & effort & power drain.

With the 3D I know what you mean. However, I've had a few signwriters sub their 3D needs in hdu out to me to cut/rout, and it's a small avenue that could be developed- just not at high speed! I've enjoyed fiddling with lithophanes, too, and a little bit of unique small trophy making.

I do like your pseudo-3d alternate methods.

-

04-06-2010, 12:25 PM #19

Registered

Registered

- Join Date

- May 2006

- Posts

- 202

Stewey,

This is a ballancing act isn't it.

Like you, I'd would like a vacuum but can't justify the expense, noise, and trouble. A TC is almost justifiable but a retro fit isn't in the cards. I'm a little long in the tooth to venture out on a new CNC. I'll be 70 this Saturday and don't know how much longer I'll be pushing this pony as hard as I've been. I'm not a high volume guy but spend considerable time on concepts and detail and production.

I can't, for the life of me, how anyone can make money with, one off, `3D. On occasion it comes in handy. For example the "R" I've posted, with the rib detail, is done in 3D. That will go fast since I'm using a 1/2' bit with 90 percent step over which leaves the fat ribs.

Here's what we use for hold downs. I made them from a discarded table.

-

03-22-2012, 12:52 PM #20

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 25

Recommended Sculpt Nouveau for steel finish

Hi Joe - I have been enjoying reading your posts. I'm in Melbourne Australia and having a crack at getting into some signage.

My first job is a bit of a mix, but it includes a large 3D crown wheel from a gear box as a logo. I have attached an image of a crown wheel.

Integrated (pocketed) into this logo will be some letters and text. The text will be more basic and graphic, in contrast to a large realistic looking mechanical part behind in the background.

I am interested in using a metal coating (iron b). But do I also need to use a patina? I don't want the crown wheel to be overly aged or weathered - just a hint of looking like machined steel.

Thanks in advance.

Malcolm

Similar Threads

-

Un nouveau Viewer 3D ultra rapide et gratuit

By carl jordan in forum FrenchReplies: 1Last Post: 06-11-2009, 08:06 AM -

Nouveau Construteur

By DanielGagne in forum FrenchReplies: 4Last Post: 05-14-2008, 01:10 AM -

using cnc machine to sculpt clay ?

By tree in forum Hobby DiscussionReplies: 11Last Post: 10-14-2006, 05:18 PM

Reply With Quote

Reply With Quote