Hi everyone. I have been building a fogless coolant mister and I thought I would share how I did it. Most materials are available at a home improvement store. I have rigged up a solenoid valve which I can actuate from EMC2. I am pretty pleased with the result, and the total cost was about $120 dollars.

Let's get started:

Step one: Go shopping (any home improvement store will get you started).

I started with the following:

Inline water filer canister (you can bin the filter as all you need is the filter)

Some 1/4 inch compression fittings

Some barb fittings

Some 1/4 inch rubber tubing (length will depend on your machine)

Various pipe fitting (plan on making a few trips)

An air pressure regulator

Results 1 to 20 of 74

Hybrid View

-

04-07-2010, 03:02 AM #1

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 76

How I built a fog-less coolant mister

-

04-07-2010, 03:12 AM #2

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 76

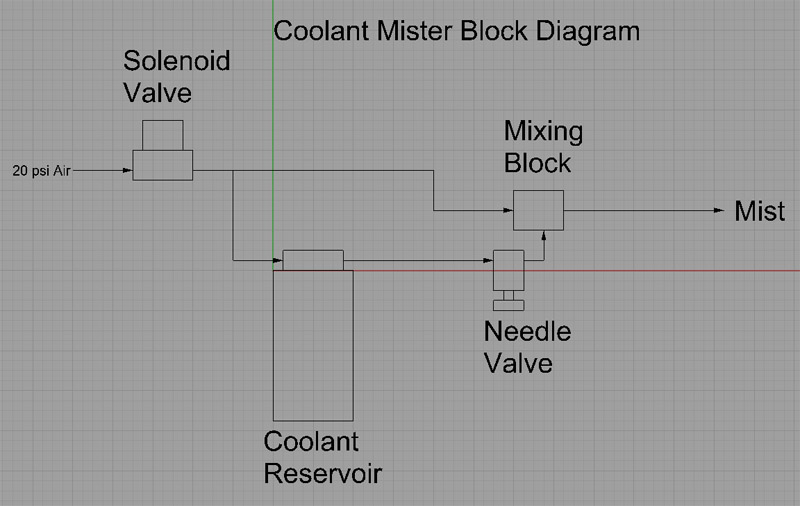

Step 2: start plumbing

This system works by putting air pressure on the top of the coolant to force it out to the nozzle where it is mixed with air. We need to be able to get the coolant out of the bottom of the canister. We will need a special fitting to do that. I did this by turning down a barb fitting and soldering it to a compression fitting. This way I can feed a hose to the bottom of the canister and seal it at the outlet at the top.

-

04-07-2010, 05:08 AM #3

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 76

Step 3: build a nozzle

You need to build a nozzle to mix the coolant and air and get that to where you want it. You do not have to follow my dimensions exactly. The key concepts are that you need a very small outlet nozzle to choke down the air flow and maximize the velocity. You also need a small passage for the coolant since the coolant flow rate will be much less than the air flow rate.

I made mine from brass so I could solder it. The pressures in the system are low enough at this point that you could easily use aluminum or something and just epoxy things together. The nozzle is brass rod which I bored from both ends with a 3/32 drill bit (hence the short length). Then I added an extension which is bored most of the way with 3/32, then through with 1/16 drill bits.

See my drawing.

I also whipped up a little mounting arm. You can copy my design if you like. It clamps to the spindle collar and articulates in 3 points. CNC helped for this!

-

04-07-2010, 05:13 AM #4

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 76

Step 4: Wrap up the plumbing

I added a solenoid valve and an air nozzle to clear off chips. I also made a mounting bracket. I added the tubing from the nozzle to the canister.

-

04-07-2010, 05:22 AM #5

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 76

Step 5: Pause for reflection

The mister works very well. I run about 15psi and the coolant and air use is pretty minimal. I wrapped the tubing in vinyl tape for protection. It looks a bit low rent, but it was the best idea I could come up with.

Mistakes I made that you should avoid:

I initially had plastic lines from the canister to the nozzle. They were too stiff and would pull the nozzle all around as the machine moved. I switched to 1/4 OD vinyl tubing and am much happier.

I initially had copper tubing for the nozzle. This was very flimsy and in my opinion the wrong inside diameter to work properly. The brass is much better. I have seen some examples where a MIG welding tip was used a nozzle. It might work.

The mounting bracket needs to be strong. Mine is too weak.

I added a barb fitting to the end of the tube inside the canister to give it some weight and keep it on the bottom.

Thanks everyone.

-Wes

-

04-24-2010, 02:54 PM #6

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 11

Hi, Wes:

I would like to build this design: it seems to use a lot of OTS components, which i like.

Could you provide a bit more detail on the plumbing arrangement between the air supply and the canister and nozzle? I guess you have a T in threre somewhere to supply air to the top of the block and the canister also?

Sorry for the elementary questions..

-

04-07-2010, 03:33 AM #7

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1542

http://www.machinistblog.com/

Or the originals:

I just had about my 100th request to make a copy of my zero fog mister. its

a device to spray coolant without that annoying fog the cheap misters put

out. Anyway I looked up the links and thought I'd repost here also.

Karl

http://www.metalworking.com/dropbox/...Fog_Mister.txt

http://www.metalworking.com/dropbox/...Fog_Mister.DWG

http://www.metalworking.com/dropbox/...Fog_Mister.JPG

http://www.metalworking.com/dropbox/...Fog_mister.pdf

http://groups.google.com/groups/sear...nsend&safe=off

-

04-08-2010, 07:24 PM #8

Registered

Registered

- Join Date

- Jul 2008

- Posts

- 922

great write up!

-

04-10-2010, 04:00 AM #9

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 237

How does this set up eliminate the fog?

-

04-10-2010, 05:00 AM #10

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 76

CalG,

Most misters use a venturi effect to pull coolant up from a reservoir to a mixing block to mix it with air. The side effect of this venturi is that the coolant is atomized, or turned into tiny, tiny droplets dispersed in the air. This atomized coolant is not dense enough to to follow the stream of air and can float up as "fog".

A fogless system uses air pressure to force the coolant from the reservoir to the mixing block. The coolant droplets are much larger (and there are fewer of them). These larger droplets tend to stay inside the air stream and avoid forming "fog".

See this diagram which I lifted form Bob Warfield's site www.cnccookbook.com.

-

04-10-2010, 06:07 AM #11

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 669

Good tech, thank you.

-

04-10-2010, 02:53 PM #12

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 237

Ahh

Air stream entrained coolant drops. Makes sense Thanks

-

04-10-2010, 03:14 PM #13

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

I have a cautionary note:

You are using a clear plastic domestic water filter housing.

My shop has used these for coolant filters for years without problems and I have suggested their use many times here on cnczone. Recently, however, someone did install one and the plastic housing fractured making a bit of a mess with coolant all over the place.

With your setup the housing is under air pressure, not liquid pressure, and when it is almost empty of coolant it is almost full of air at 15 psi; if this housing fractured it could fling plastic shards around.

A metal shroud around it may be a good idea.An open mind is a virtue...so long as all the common sense has not leaked out.

-

04-10-2010, 09:03 PM #14

I used an ex propane tank on Karl T's design.

http://www.cnczone.com/forums/showthread.php?t=87439

Post #11

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

04-10-2010, 10:39 PM #15

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 76

The water filter canister is rated for over 100psi, and pressure is pressure, whether it is water or air. The commercial unit from Hench uses the same sort of clear canister. Of course, if you drop the canister or something, it will be weakened. Still, I am only at 15psi.

I will try to post a video of the unit in action.

-Wes

-

04-10-2010, 11:13 PM #16

Gold Member

Gold Member

- Join Date

- Jul 2005

- Posts

- 12177

No, pressure in the form of a gas can be much more hazardous than pressure in a liquid. Liquids do not compress, at least not measurably at low pressures, gases do compress. When a pressure vessel containing a liquid ruptures the pressure is lost almost instantly and the escaping liquid does not propel the fragments of the container anywhere. When a pressure vessal containing a gas ruptures the gas expands rapidly, potentially propelling fragments of the container in all directions at high speeds.

You can choose to disbelieve but you can demonstrate the difference quite easily. Fill a balloon with air, stick it with a pin and you get a bang and the balloon tears widely. Fill a balloon with water to the same volume, stick it with a pin and you just get a sploosh.. The pressure inside the balloon is the same in both cases.An open mind is a virtue...so long as all the common sense has not leaked out.

-

04-11-2010, 12:27 AM #17

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 76

I am not going to tell anyone they should not be careful with pressure vessels.

Everyone understands that gases are compressed under pressure. No one is trying to say that explosive decompression is not dangerous. However, I have a 500% safety factor at 20psi. These units are in widespread commercial service. I doubt Hench would still be selling Fogbuster units if the coolant canisters all exploded. I also feel that using the water filter canister is much safer than the homemade jobs I have seen while researching for this project.

This may be a good time to say that this unit is potentially dangerous and operates under pressure. All users should understand the risks of this type of device before undertaking its construction or operation.

I will leave it at that.

-

04-10-2010, 11:28 PM #18

Gold Member

Gold Member

- Join Date

- Mar 2004

- Posts

- 1804

Geof is absolutely correct! I have seen the results of both. When I was young and stoopid, I used some pvc on an air line. Fortunately, when it let go, I was not in the building! As a fire protection engineer, I have seen water pipes burst and the result is a lot less dramatic:})

Art

AKA Country Bubba (Older Than Dirt)

-

10-29-2012, 01:42 AM #19

Registered

Registered

- Join Date

- Mar 2009

- Posts

- 139

Any updates/improvements in this project?

I plan to build a fog-less mister for my Sherline mill and lathe but would like to know if anyone has made some improvements to the basic design. I am particularly interested in the size of nozzle orifice.

CheersNorbert

-

10-29-2012, 12:31 PM #20

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1542

Similar Threads

-

CNCRouterStore.ca now offering a Unist Coolant Mister

By CNCRouterStore in forum News AnnouncementsReplies: 0Last Post: 01-17-2014, 04:33 PM -

Coolant Mainifold Built

By gtiworks in forum Charter Oak Automation Support ForumReplies: 1Last Post: 10-30-2013, 04:20 PM -

Question about using WD-40 as coolant in my Kool Mister instead.

By Big Daddy in forum MetalWork DiscussionReplies: 12Last Post: 05-31-2012, 03:14 AM -

Coolant mister problem(homebrew)

By mwood3 in forum Benchtop MachinesReplies: 6Last Post: 10-18-2010, 03:14 AM -

Mister versus flood versus ??? coolant system

By split63 in forum Bridgeport / Hardinge MillsReplies: 14Last Post: 10-02-2006, 11:18 AM

Reply With Quote

Reply With Quote