I am getting chatter during any change of direction (x,y) at any feed over 20ipm and nobody can seem to figure it out. The chatter is only for a split second after directino change them it will run smooth as glass. This machine would be perfect if I could only fix this issue. Its a 96 4020,dc motor, box way, 10k spindle, 700ipm rapid, 88hs control.

Here is what we have done so far.

-checked gains. they are good.

-replaced x,y resolvers

-replaced x,y gibbs

-checked table flatness. within a couple thou.

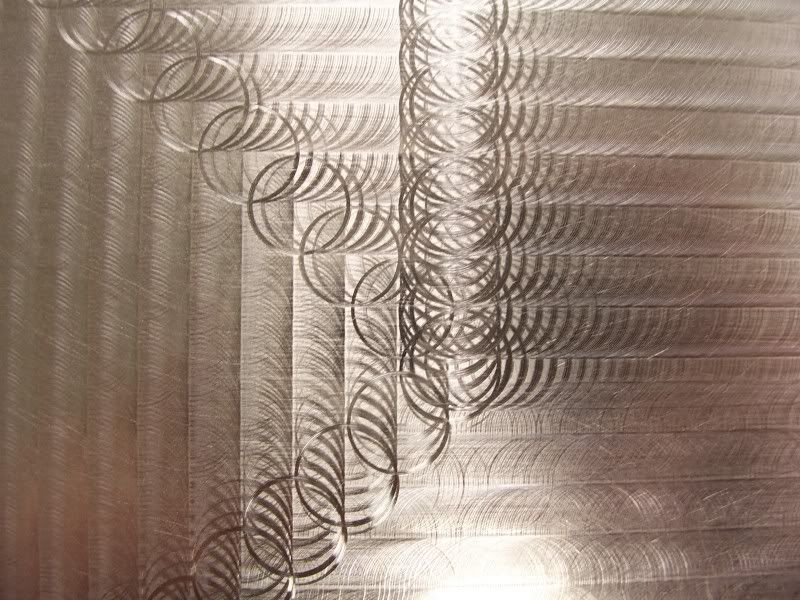

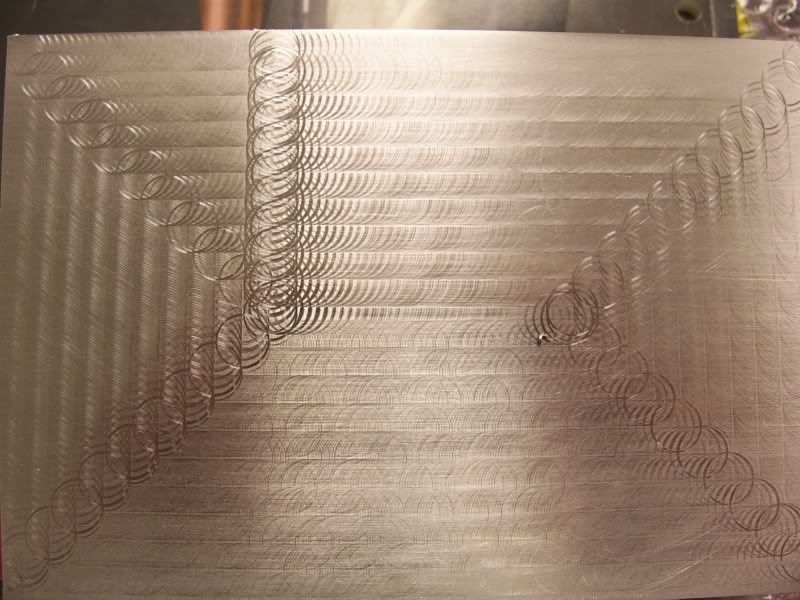

Anyone with any further ideas? Here are some pictures of the issue. This was 80ipm.

Thread: Fadal 4020 mystery chatter

Results 1 to 14 of 14

-

06-08-2010, 02:55 PM #1

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 21

Fadal 4020 mystery chatter

-

06-08-2010, 03:28 PM #2

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 317

Check Spindle bearings preload; drawbar tension.

-

06-08-2010, 03:31 PM #3

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 21

Both techs checked the drawbar tension and it was good.

-

06-08-2010, 03:35 PM #4

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 317

It is Pozy belt driven or 6 belts?

-

06-08-2010, 03:51 PM #5

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 21

two large belts. one for high one for low. just replaced belts and cleans entire assembly yesterday before rerunning part in pic.

-

06-08-2010, 04:05 PM #6

Monkeywrench Technician

Monkeywrench Technician

- Join Date

- Jan 2004

- Posts

- 3154

How about XY thrust bearings

www.integratedmechanical.ca

-

06-08-2010, 04:14 PM #7

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 21

-

06-08-2010, 08:44 PM #8

Registered

Registered

- Join Date

- Sep 2009

- Posts

- 181

Did this problem start occurring recently or has it always happened? Did you make any changes prior to the chattering?

Need help with your Fadal? Send me a message or visit www.TheFadalParts.com. We have over 25 years of experience at Fadal and offer FREE TECHNICAL SUPPORT OVER THE PHONE!

-

06-08-2010, 08:53 PM #9

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 21

-

06-08-2010, 08:58 PM #10

Registered

Registered

- Join Date

- Sep 2009

- Posts

- 181

Can you send me your phone number? I will do my best to help you out and we can post the results here to help anyone else who may be having this issue as well.

Need help with your Fadal? Send me a message or visit www.TheFadalParts.com. We have over 25 years of experience at Fadal and offer FREE TECHNICAL SUPPORT OVER THE PHONE!

-

06-09-2010, 12:32 AM #11

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 376

My 2 cents, take it for what its worth.

Looks like a deflection issue, where you are getting the gouging is where the cutter goes from having more material to cut to less material to cut. Also look at your witness marks, they clearly show that you are deflecting as you circle the part, and it also looks like your head is a bit out of square tilted a bit towards X positive.

I'm running pretty close to the same path you are right now in 13-8, I'm showing only the leading edges of the endmill all the way around(deflection), I'm running .400 deep, .300 wide with a half inch endmill, square corners.

The corners are just showing a pattern overlap, no gouging, with that info...

My diagnosis is Z axis thrust bearings.

What material, chipload, we already hit feed, depth of cut, endmill, tool holder?

I'll take another guess, it looks you are feeding about 15% of your diameter per rev, and your tool is either running out or dragging a chip.

Interesting problem

-

06-09-2010, 02:01 PM #12

Monkeywrench Technician

Monkeywrench Technician

- Join Date

- Jan 2004

- Posts

- 3154

Or gibs set too loose on Z.

www.integratedmechanical.ca

-

06-13-2010, 09:21 PM #13

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 127

Are you rolling the cutter around corners or just slamming it into a 90 degree turn? If it's engaging a decent amount of material, then I could see it getting pretty angry about an instant-turn.

-

06-14-2010, 05:47 AM #14

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 41

machine is not anchored into concrete

feed rate too high for the directional changes

causing machine to shake (bounce)

program radi in corners problem goes away

Similar Threads

-

Fadal 4020

By joshuac in forum FadalReplies: 10Last Post: 09-10-2010, 11:36 AM -

FADAL 4020 Z-AXIS WON'T GO!

By TRACYPFAB in forum FadalReplies: 3Last Post: 05-27-2010, 02:44 PM -

96 Fadal 4020 TurboCadCam

By ThatguyDave in forum FadalReplies: 1Last Post: 08-28-2009, 07:27 PM -

FADAL VMC 4020

By dmac88 in forum FadalReplies: 7Last Post: 05-18-2009, 08:45 PM -

How do I tell the age of a FADAL 4020?

By Rickady in forum FadalReplies: 8Last Post: 07-10-2007, 12:02 PM

Reply With Quote

Reply With Quote