You might want to take a look at how I did mine. I did use the gas pipes at first but had problems with flex. I then tried filling the pipes with cement. That did help but I still had too much flex. I then did away with the pipes and mounted angle iron to the lower bed. The bearing assy that used to ride on the pipes was then mounted on the bottom of the gantry and now ride on the angle iron. On the bottom of the upper table I mounted another piece of angle iron and installed two more bearings to prevent the gantry from tipping over. You can see my machine in action at youtube. [nomedia="http://www.youtube.com/watch?v=aWwokuCNBEo"]YouTube - DIY CNC Router (JGRO) Toolbox Foam Layout pt1[/nomedia]

Take a look around 3:40-4:40

I cant remember what this cost but it's got to be the cheapest option other than JGRO's gas pipe idea.

Results 21 to 28 of 28

-

11-05-2010, 01:16 AM #21

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 8

-

11-05-2010, 03:06 PM #22

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 177

Andypcguy,

do you have any pics to put up for us who cannot view youtube at work

Tom

-

12-04-2010, 09:18 PM #23

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 50

Would anyone like to make a list of their favorite collets and bits and share that with the community? I use a Craftsman router on my machine, isn't that the same as Porter-Cable (for collet size)?

-

12-05-2010, 01:15 AM #24

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 144

I am using a Craftsman router also. I use the Precise bits collets and nut.

The craftsman router uses the same collet and nut that is compatible with Bosch 1617, 1618 & 1619 routers and Hitachi M12VC &KM12VC routersJGRO Complete - G540, 380oz Nema23s, 1/2-10 ACME, 30"x14", Craftsman router

Joes 4x4 R&P in progress

-

02-16-2011, 09:32 PM #25

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 17

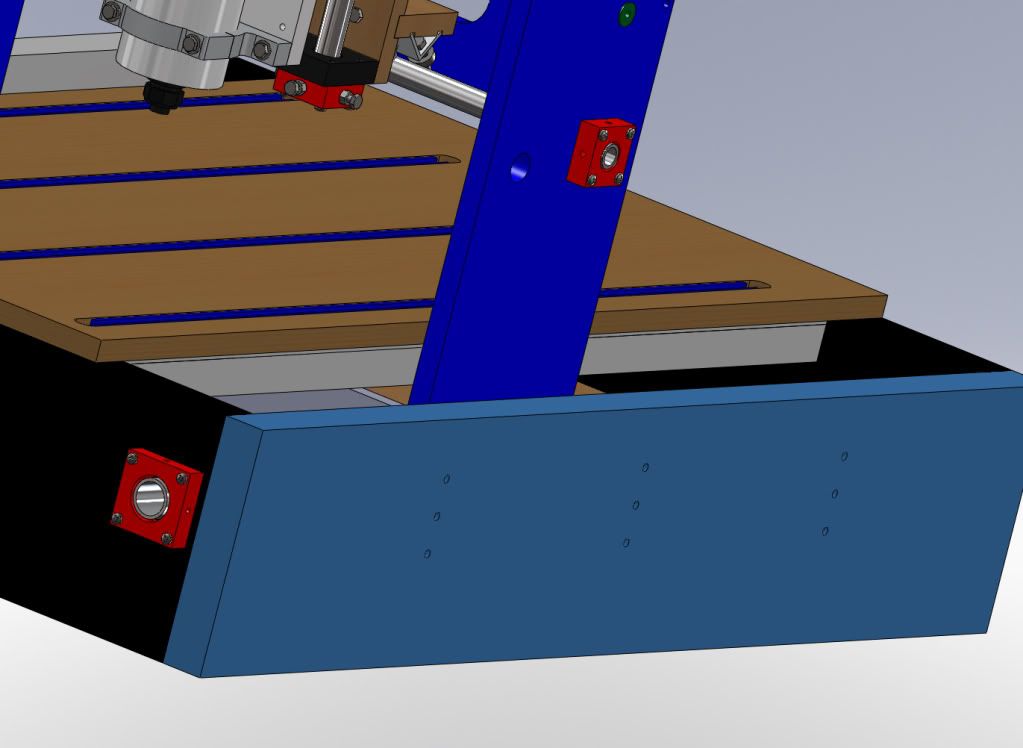

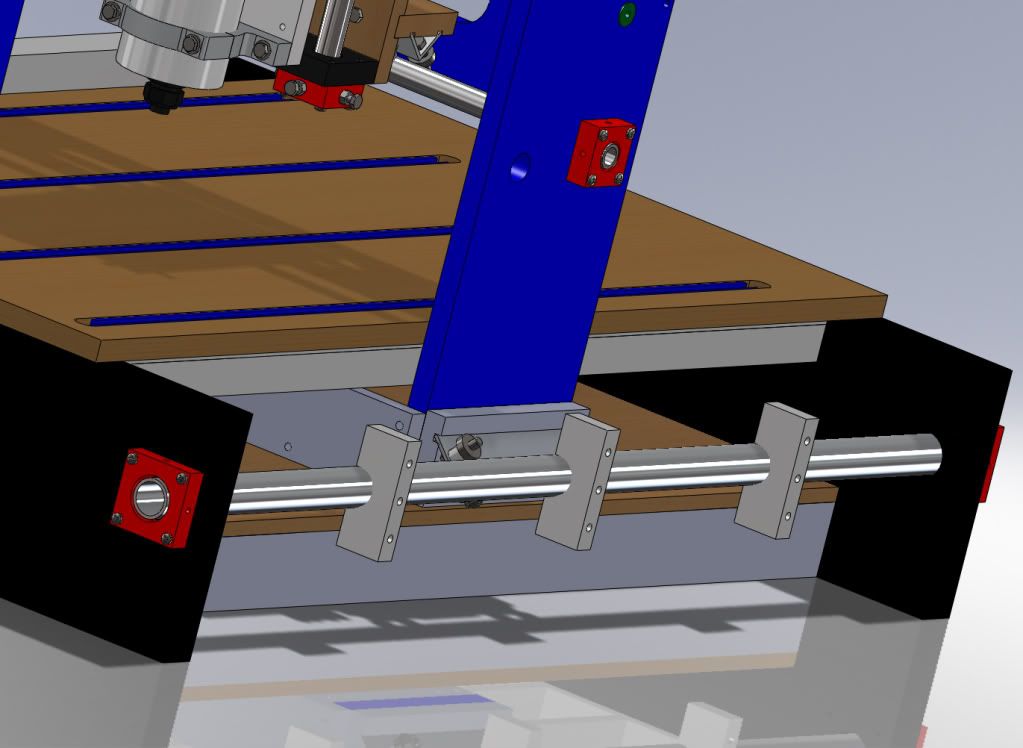

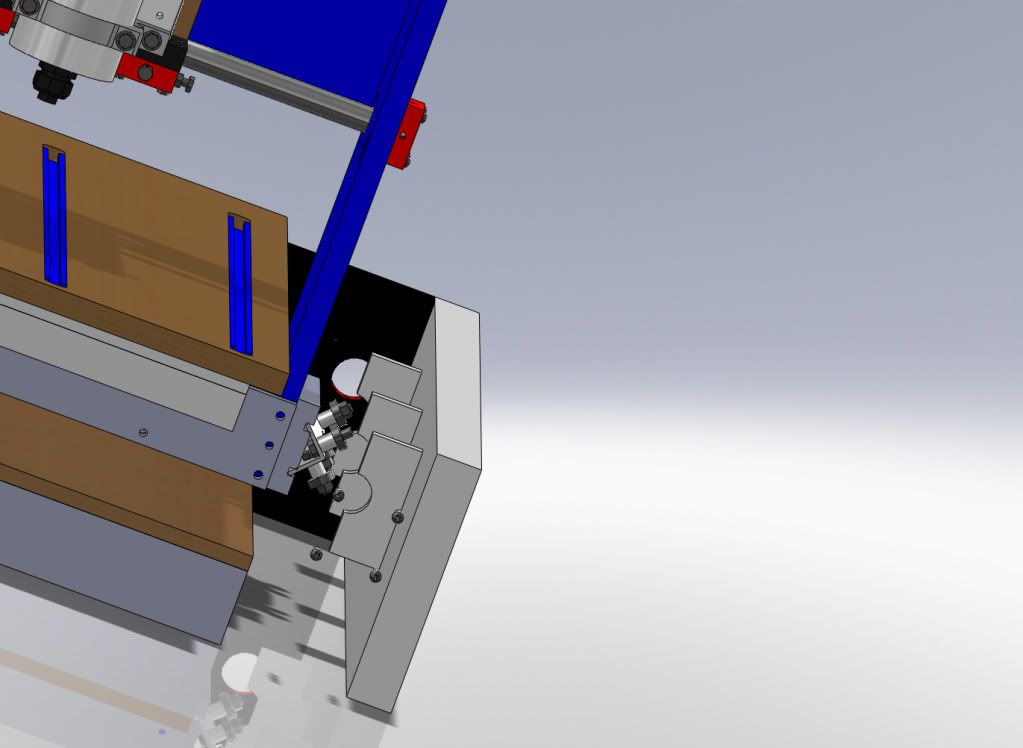

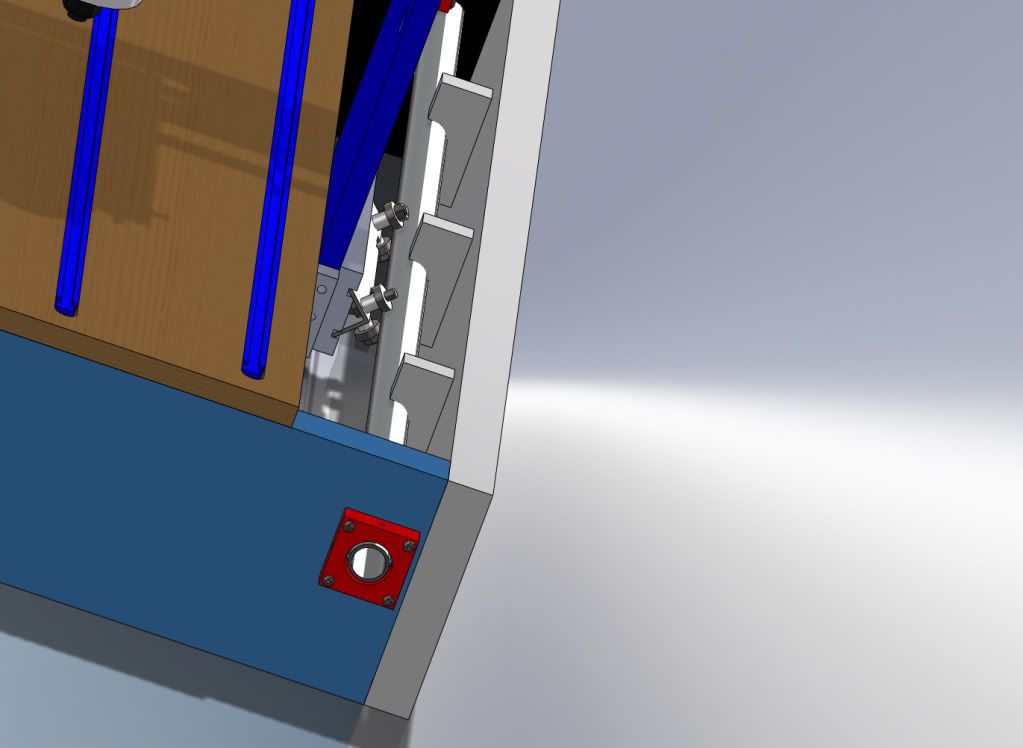

you can add a side panel with tube supports and drill thru the tube and mount the tubes to the wall so there is no flex as show in these pics:

sorry they are a bit big..

-

10-09-2013, 07:01 PM #26

Junior Member

Junior Member

- Join Date

- Sep 2013

- Posts

- 16

Jpike, I really like your support for the X rails. I was going to modify my plans for the JGRO and mount the pipe rails for the X axis directly on the base but that left the gantry unstable. Your brackets will allow me to build it from plans and just add the supports that you used. Very nice indeed.

Could you list your choice for motors and lead screws. I have the Gecko 540 on the way and want to use motors that will provide reasonable speed and torque.

I was thinking of ordering the G723-280-4 or G723-400-4 280 oz in or the 400 oz in NEMA 23 motors from Gecko. I am not sure of which lead screw to use but was thinking of the 1/2 -10 ACME 2 Start. I would welcome all opinions. I would like to use the same lead screw on all 3 axis.

Thanks in advance, JR

-

10-09-2013, 07:34 PM #27

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 483

You need to keep in mind that the rails have adjustment blocks where this style of support is static. You should design some sort of adjustment capability in the supports as well.

I think it's generally agreed that 380oz motors are the best match for the g540Could you list your choice for motors and lead screws. I have the Gecko 540 on the way and want to use motors that will provide reasonable speed and torque. I was thinking of ordering the G723-280-4 or G723-400-4 280 oz in or the 400 oz in NEMA 23 motors from Gecko.

If you are going with 1/2" -10 acme then 5-start is what you want even for the z.I am not sure of which lead screw to use but was thinking of the 1/2 -10 ACME 2 Start. I would welcome all opinions. I would like to use the same lead screw on all 3 axis.

-

10-10-2013, 06:37 PM #28

Junior Member

Junior Member

- Join Date

- Sep 2013

- Posts

- 16

Thank you. The adjustable mounting for the added rail support is on my list.

I think I should go with the G723 400 oz in motors from Gecko.

If I use the 5 start ACME lead screw will it load the steppers a lot more than the 2 start?

I figured the 5 start would provide faster axis motion but at a cost of higher loading on the motors.

Similar Threads

-

Favorite Swiss cutting oil??

By PoiToi in forum CNC Swiss Screw MachinesReplies: 16Last Post: 01-25-2019, 10:01 PM -

Favorite Mods

By doanwannapickle in forum Taig Mills / LathesReplies: 2Last Post: 09-13-2009, 11:09 PM -

Favorite G offset?

By Trapper14 in forum G-Code ProgramingReplies: 4Last Post: 08-14-2006, 03:02 PM -

Favorite Camsoft trick

By Karl_T in forum CamSoft ProductsReplies: 17Last Post: 08-07-2006, 08:24 PM -

What is you favorite printer?

By cncadmin in forum Printing, Scanners, Vinyl cutting and PlottersReplies: 4Last Post: 09-25-2005, 03:21 AM

Reply With Quote

Reply With Quote