Ok, so as per this thread:

http://www.cnczone.com/forums/showthread.php?t=111068

Ok, so I am following the advice that Al the man had given me. And I cannot get it to respond. Here is a video of my problem.

[nomedia="http://www.youtube.com/watch?v=mKPQgBHNEe4"]YouTube - MVI 0322[/nomedia]

Thanks, for the help guys.

Results 1 to 20 of 30

-

09-13-2010, 08:32 PM #1

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

Fanuc 10TF Controll, trying to upload parameters but.......

-

09-13-2010, 08:45 PM #2

The last time I saw the photo of your MB it showed E on the seven segment display, if it is still there, you still have a hardware/firmware problem.

This is System Error: Cause: Master PCB, NC software ROM or RAM board.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

09-13-2010, 08:58 PM #3

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

There is a 0 on the 7 seg display now.

-

09-13-2010, 09:06 PM #4

Gold Member

Gold Member

- Join Date

- Jun 2008

- Posts

- 1511

For the sake of having to read the 4+ pages of posts I have a few questions.

Providing it is not a hardware problem as Al has stated have you tried doing any of the master clears?

To do a master clear

power on with "7" and "9" depressed

IPL screen will appear press "99" "Input"

clear "Y" then it will ask you axis. This is the number in #9000

next it will ask you option #1? press "Input"

Press "Input" through all options. Should only be 32 options

It will ask to clear data or memory hit "Y"

Then select option "6" to exit IPL

To clear and set FAPT side.

Power on holding the "BS EOB" button

FAPT screen will appear. Press soft key "AUXULIRAY"

Type in data "CFINT" press input

It will ask yes or no to initialize press "1" for ok and input

Screen will message you when complete

To enter in option parameters

1) Power up machine with "-" minus and "." decimal point depressed

2) Key "99" and "Input"

3) Key in "3" or whatever # axes in parameter 9000 @ "AXIS" prompt

4) Step through options by number and key new Hexidecimal codes and "input"

option 1=9100, option 2=9101 ect. Just push input if no change is required

5) If "clear files" appears, hit "Y" - will erase programs etc.

6) When 1st menu appears, key "6" and "enter"

Stevo

-

09-14-2010, 01:25 AM #5

Yeah, Stevo1 has the right information.

I found some more notes on the web on your problem.

http://www.cnczone.com/forums/archiv...hp/t-6252.html

http://cncforums.machinetoolhelp.com...bel-error.html

http://gefanuc.bnsi.net/eforum/showthread.php?t=13140

I was looking for others but these might help and there might be others on those other forums.

Greg

-

09-15-2010, 01:48 AM #6

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

Ok, now I have a 1 on the 7 seg display.

Ok, now I am trying to enter parameters. I go to the 8000 parameter, and type 1 then imput, so it will unlock the parameters, but in purple letters, it says write protect. I have the write protect keyed switch to the opposite way of lock. Any Ideas?

-

09-15-2010, 12:20 PM #7

Gold Member

Gold Member

- Join Date

- Jun 2008

- Posts

- 1511

Do you have your option parameters entered?

You need to make sure that you are setting the PWE bit in parameter 8000 under the “settings” softkey and not the “service" softkey. You may also have to be in Estop mode.

Stevo

-

09-15-2010, 08:42 PM #8

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

Ok, you were correct, I was trying to enter parameter 8000 in the service, not the settings.

Ok, now I got all of the parameters entered, as well as the keep relay, timer, data table control.

Sure alot of info there.

Anyways, I set setting 8000 back to 0, powered the machine down, and back on, and am getting an error, or E95, on the fapt side. I cannot get the machine to do anything at all. The little alarm led is on, but in the nc part of it, under the alarm, there is no alarm.

Any Ideas?

-

09-15-2010, 09:08 PM #9

Gold Member

Gold Member

- Join Date

- Jun 2008

- Posts

- 1511

I don't know exactly what the E95 alarm is and I don't have a 10series manual to look it up either. I am going to speculate and say try doing the FAPT clear and set procedure that I posted above.

Stevo

-

09-15-2010, 10:03 PM #10

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

Ok, I have done a FAPT clear. Now the FAPT is fully functional it appears, it shows material types, and shapes to machine.

The error was like this:

*E95 C-Ram Parity Error (high):80000

Now once I did the FAPT clear, the fapt seems to be ok, But I still have the alarm LED on. I cannot find any alarm in the message page, or on the fapt side.

I cannot get the hydro pump on either, or energy to the servos. Does this work like other yasnac machines where you have to push the on switch twice to get the servos on? I tried it and it does not work. There is only one E stop I can find right on the main crt panel. Any Ideas?

-

09-16-2010, 12:56 AM #11

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

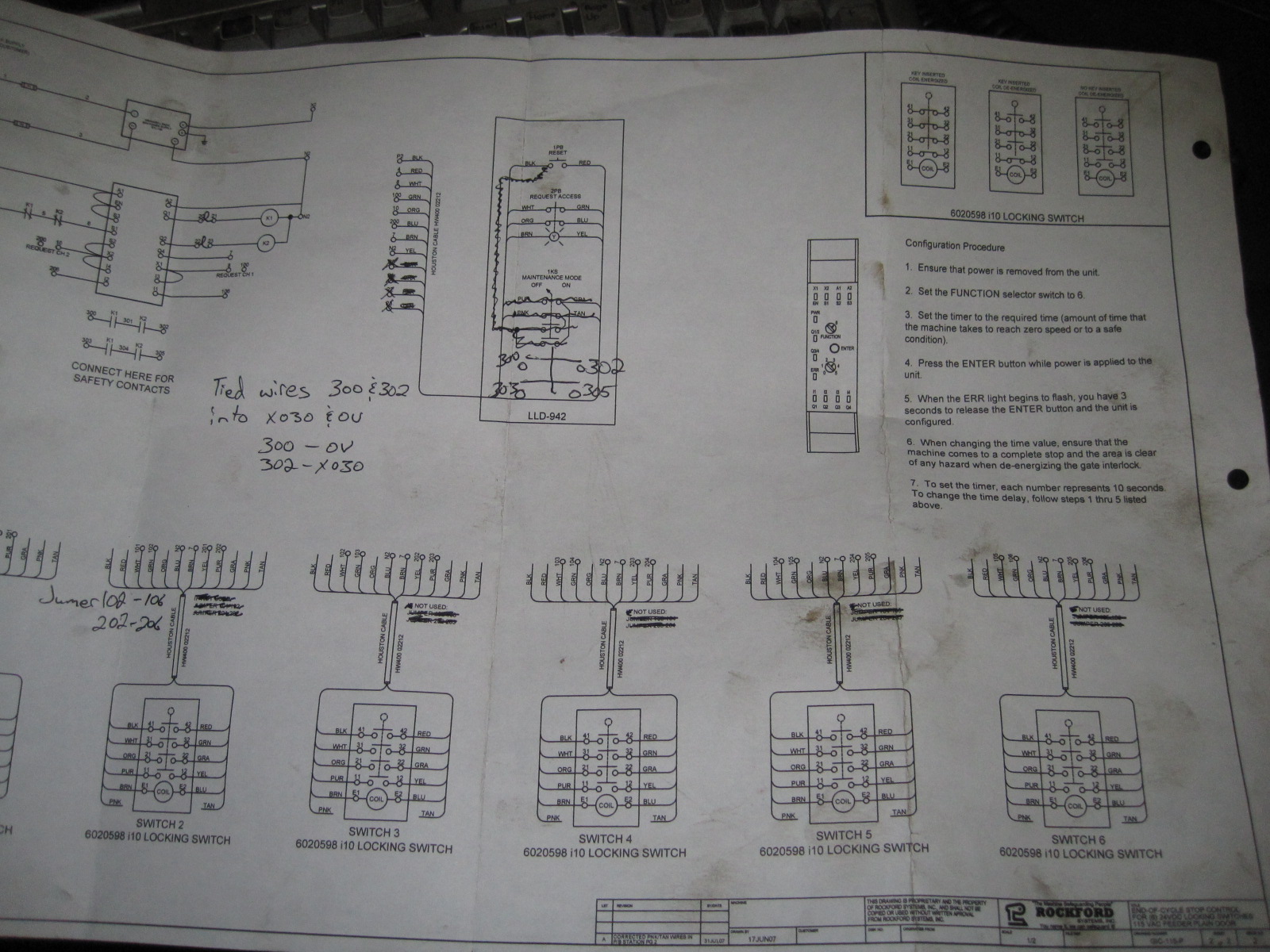

Ok, I think it is related to whatever honeywell had as their interlock system. As you can see they added buttons to the crt panel, as well as a bunch of relays and wiring. Can any of you guys decifer what they did? Here are some photos.

This is inside the control panel:

-

09-16-2010, 01:17 AM #12

What happens when you rotate the function switch, does it show the functions on the screen just above the soft keys?

Not sure what that 'Maintenance Mode' does?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

09-16-2010, 01:19 AM #13

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

This electrical schematic was in the cabinet. I belive it has something to do with it.

-

09-16-2010, 01:28 AM #14

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

No the soft keys do not change, say when I am in program mode, when I rotate the function dial, ie, mdi, edit, memory, handle, etc.

-

09-16-2010, 01:28 AM #15

If you do not see the different functions appear on the screen when you rotate the switch, the PMC is not running/reading the switch?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

09-16-2010, 02:47 AM #16

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

I can veiw the ladder on the screen. There are TONS of pages, in there. Is there something specific I should look for in the ladder? Where should I go from here?

-

09-16-2010, 03:19 AM #17

Actually the easiest way is to look at the diagnostic I/O screen, the first page or so should show the bits changing when you turn the switch, usually set up as a binary code.

if you do not see bits changing, make sure you have the 24vdc on the switch.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

09-16-2010, 04:53 AM #18

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

Ok, I can check that in the morning. What two pins on the switch should I check for 24vdc?

-

09-16-2010, 03:07 PM #19

No two functions switches are the same.

The 24vdc common is often at ground potential, if so you can measure the pins to ground for 24vdc.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

09-16-2010, 06:06 PM #20

Registered

Registered

- Join Date

- Jan 2009

- Posts

- 245

Ok, on the diagnosis screen, the digits do change when I rotate the switch. On Number three it reads like this:

mem=00100000

Edit mode=01000000

MDI=00001000

Jog=00000100

Zero Return= number three line=00000100

number 02 line goes from 00000000 to 00000010

But this is the problem I belive. They have a tie into another interlock, somewhat the same as the Estop I say this because on the lower part of the screen in the NC mode, it always says "HND RESET EMG" No matter if the Estop is pushed or released. I would think when you hit the estop or release it, it would show on the screen.

Honeywell had some sort of interlock system, like I showed previous photos of in this thread, that I think they tied somewhere into the Estop circut. That is why it always says that on the screen.

Similar Threads

-

How to dump (and upload) parameters on O-M

By padobranac in forum FanucReplies: 4Last Post: 07-25-2008, 08:30 PM -

fanuc 10tf

By morris in forum FanucReplies: 0Last Post: 04-17-2008, 04:20 PM -

Fanuc 10TF PMC Parameters

By leturc in forum FanucReplies: 3Last Post: 03-18-2008, 04:42 AM -

proceedure upload heidenhain parameters

By bbrreid in forum Bridgeport / Hardinge MillsReplies: 6Last Post: 03-01-2008, 01:42 AM -

Fanuc 10tf Alarm

By L. Sakthivel in forum FanucReplies: 1Last Post: 05-30-2007, 04:49 AM

Reply With Quote

Reply With Quote