Well guys, I’m taking the plunge, dropping the dough, and starting my low budget 4x4 Plasma table build!!! I have been working on the table for a few days on and off now… and starting to show some progress… at least some I can show to others anyways… lol…

I hope no one minds and going to post links to where I got my supplies as I go along… None of which is my sites or promoting anything for myself… Just trying to help other starting out like me!... If I’m breaking a rule here… Please let me know!

I am going to be using the “PlasmaBot” by NoSleepStudio… a local guy here on the “Zone”…. UserName: tulsaturbo…. Through him I sourced all my gantry ends, carriages, stepper motor mounting plates, & build source sheet from him… Pretty much an entire kit already cut and put together and ready to go… Just add table and electronics!... A link to his site… NoSleep Studio

I purchased my 23 nema 420oz. Steppers, Driver board, and Cable Track from Brent Hubbard… A cnc supply store on ebay…Might be on here as well… I’m unsure… Really good deals on cheap electronics to get me started!... A link to his auction store… HUBBARD CNC INC items - Get great deals on POWER SUPPLY WALL TRANSFORMER, LOVEJOY DRIVE COUPLINGS items on eBay Stores!

I would like to say up front, I know my garage is a mess. It has been on average about 15F degrees +/- for the last few months… very cold and takes so long to heat the place up, so less time to clean for now… I should have gotten my trailer all loaded up before the snow hit and before putting in it storage for the winter… Space is limited for now, new garage coming in the summer!...

Results 1 to 20 of 341

-

02-12-2011, 11:52 PM #1

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Starting my "PlasmaBot" 4x4' table build!!!

Starting my "PlasmaBot" 4x4' table build!!!

-

02-12-2011, 11:55 PM #2

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I had my local yard cut all my steel to length for me, making my life a little easier! All of my 1x2” & 2x2” steel has a wall thickness of 0.110… Nice, thick and heavy!... Learning as I go along!

Steel Table Cut list: Total cost ($165)

2) 1x2x56”........Top Rails

2) 1x2x44”........Side Bottom Rail

2) 1x2x56.5”......Front Bottom Rail

2) 2x2x56.5”.......Top Cutting Area

2) 2x2x44”.........Top Cutting Area

4) 2x2x35”..........Legs

1) 6x6 3/8..........Wheel/Feet Supports

-

02-13-2011, 12:06 AM #3

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Had a hard time finding a way to keep everything together to check for squareness... I do a bit of quick welding from time to time... but nothing that had to be this precise... So, I spent quite a bit of time framing it all up.... tacking it... measuring, time and time again... It was not too bad though, after making my first tack weld... I never had to grind any and re-weld a thing!

-

02-13-2011, 12:10 AM #4

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

With the extra long top Rails.... some will be trimmed off once the rails arrive for my X & Y Axis.... Top rails should end up being 55" long... Does anyone know where to find those nifty plastic caps to cap off the ends of 1x2" and 2x2" tubing???....

-

02-13-2011, 01:01 AM #5

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Try McMaster Carr they have about everything you can need.

Mike

-

02-13-2011, 02:43 AM #6

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I'll check that out thanks!...

-

02-13-2011, 02:44 AM #7

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

a few more of the progress....

-

02-13-2011, 02:15 PM #8

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

02-14-2011, 01:01 AM #9

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Well, got some painting done..... starting to look like a table now.... Need to light sand her a bit more and make another pass or two.... I did not realize how much paint was in the air until i opened the garage door!... :-D

-

02-14-2011, 01:05 AM #10

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I checked her time and time again for squareness and measured diagonally from every angle.... she is true in every way.. except for literally 1mm off on the top rails... but my extrusion V-rails will take that out when i mount it...

-

02-14-2011, 01:49 AM #11

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

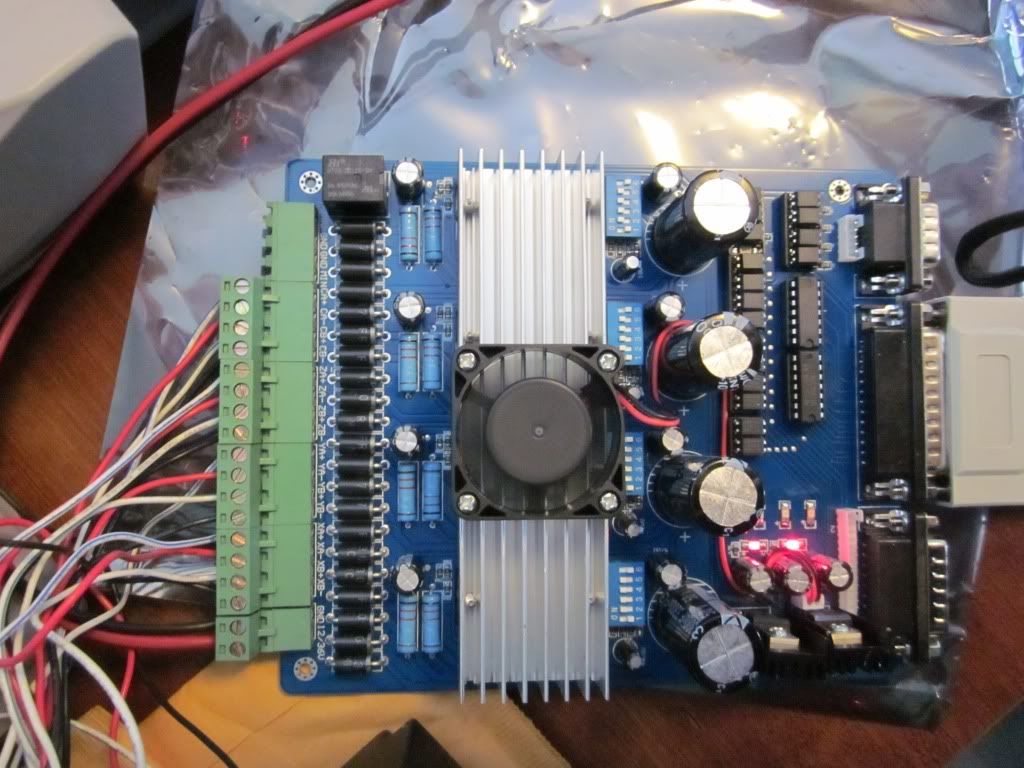

My Electronics!!!

My Electronics!!!

I got all my electronics from Hubbard CNC in the mail and all checked out!…. Brent and his wife were great to deal with and was very understanding of a novice like myself… Was even kind enough to send me detailed information on the Driver Board that I ended up going with and gave me several printouts on how to set the Board up… and not to mention they did test videos of MY board working before they sent it to me, with setup files all ready to go… I did not have to change pretty much anything about my settings…. Just drop the file they for me in place in Mach3 and she was up and running!… That is good service!... Will be buying more from these guys in the future, for my cnc mini-lathe later!...

Will post up a few photos of my electronics…. I went with the TB6560 Toshiba board, (4) 420oz Nema 23 steppers, 50’ of 18ga shielded wire (hope that’s enough!) and a 30volt 8.5amp Power Supply…. All from Hubbard…

Everything in the package shipped: Total cost ($365)

-

02-14-2011, 02:19 AM #12

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Will try and get more up tomorrow!

-

02-14-2011, 05:47 AM #13

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 95

Great progress........jm

-

02-14-2011, 09:33 PM #14

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

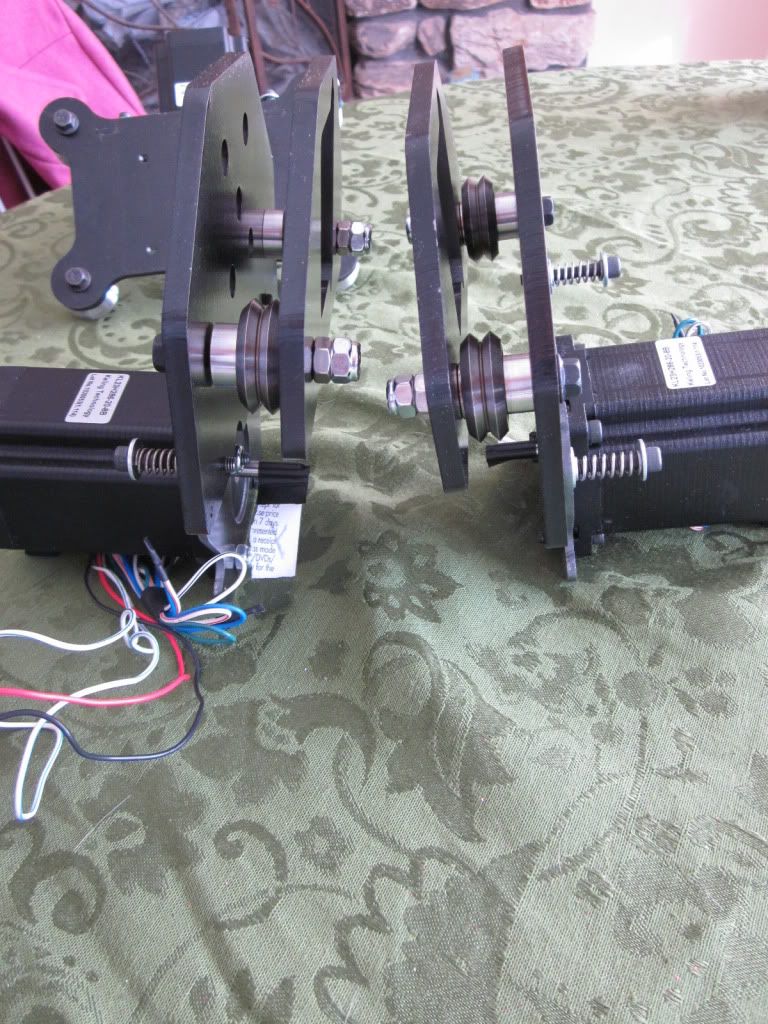

Thanks!.... a few photos of the V-bearings.... 2 eccentric bushings and the others that i made on the lathe... I made them exactly as the eccentric bushings without the offset.. This way i can keep the same 1/4-20 bolts throughout the machine.... They have a very snug fit just like the eccentric bushings as well and needed to press them in place with my shop press.... nice clean fit!

-

02-14-2011, 09:35 PM #15

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

02-14-2011, 10:50 PM #16

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Well, I got confirmation and tracking # for my V-rails and were shipped out today... They are coming from only 1 state away... UPS... so, I'm hoping to have them either tomorrow (tuesday) or the next day... Much faster than what I was told!...

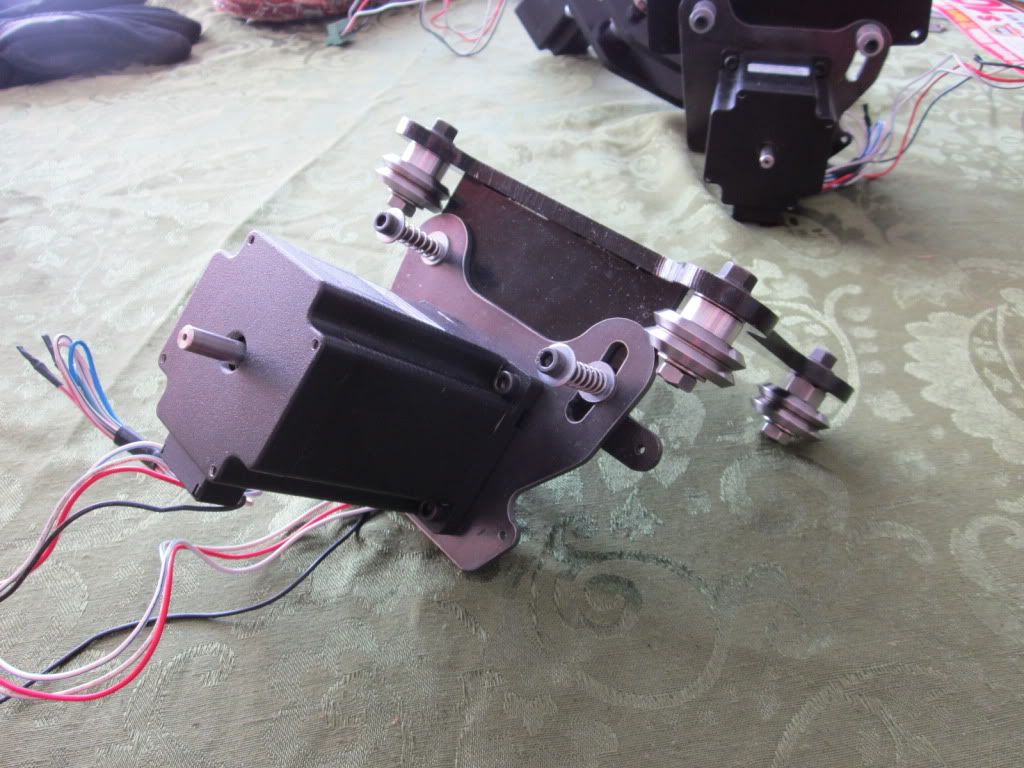

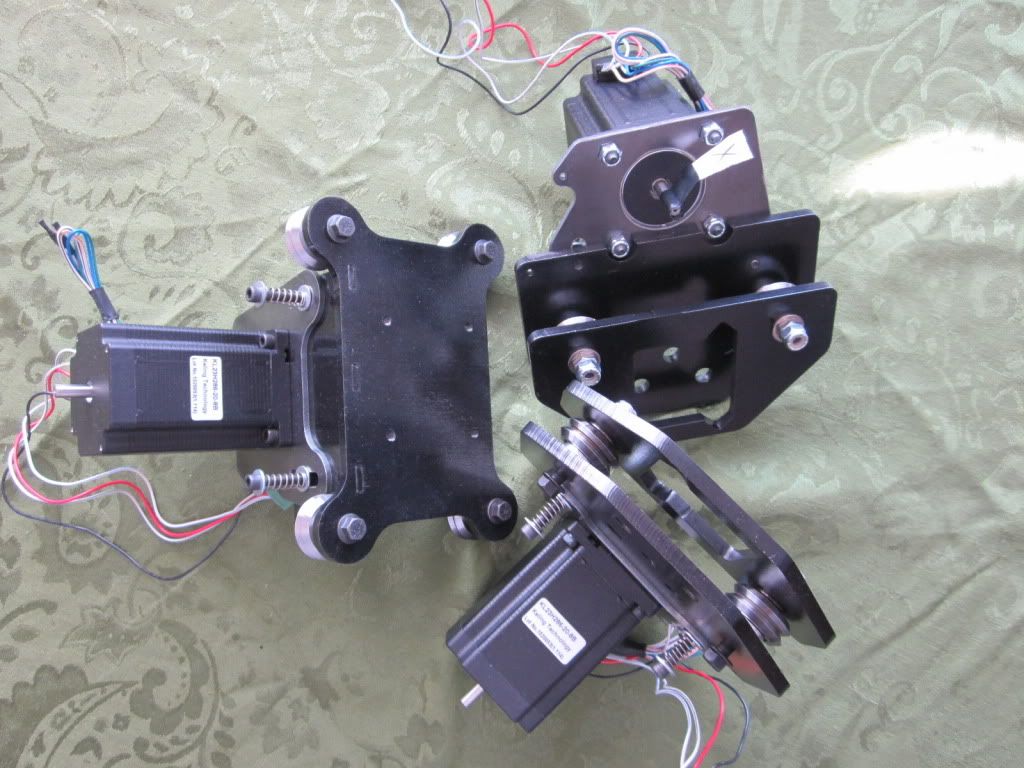

A few new photo's for you guys, loose fit to see how it all is going to work!... My PlasmaBot Kit.... Got the steppers all mounted up, testing everything all out... Today I got the heavy duty springs (on the bolts) and the ones for the tension, as well as my rack and pinion's ordered. I just wanted to test fit everything with what i had!... I honestly though i had more time before my V-rails were to be shipped, and was waiting for some dumb reason to order my last few parts... but, surprise!...

Now, I measured every for my rails like 30 times... and took in every variable that i could imagine that would happen. Just to make sure if they sent by mistake, a slightly longer or even shorter gantry V-rail... That i will not have to cut it... or change a thing with my table.... Remember the bushings that I made on the lathe for the gantry carriage?... Well I made the same ones for my X-axis and they are all EXACTLY the same... (4) for my X-axis carriages.... and (2) for my gantry Y-axis (other two are eccentric).... For the X-axis carriages, instead of using washers or etc, I will make 4 spacers for the other side of the V-bearing once my rails are here...If for some reason the Gantry V-rail is off at all.... I can just flip that bushing/bearing around to the dust shield side of my carriages and machine the (4) bushings to make up for the difference in the length of the V-rail.... make since?... If they cut my rail spot on.... I will just make up 4 spacers with 1/4 holes in the center that are going between the bearing and the black dust shield!....

-

02-15-2011, 01:54 AM #17

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

How do you like the Harbor Freight Plasma cutter?

Are you going to use that for your CNC torch?

-

02-15-2011, 02:26 AM #18

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Keen eye!... I have put an hour or two of use on it... cuts just like a plasma cutter!... Or... a hot knife through butter!.. I know that the duty cycle is not that of a higher dollar unit... but I will not be cutting anything thicker than 3/8... and most of the time,1/4" or thinner.... so, duty cycle should not really come into play... If i have to cut through something elaborate and time consuming then I can hit the "pause" button for a bit and come back to it... This will not be a production machine by any means... just cutting parts for myself for my vehicles and some friends!...

Cant really beat the price either!...

-

02-15-2011, 03:37 AM #19

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I really like your approach to this build. I was checking out the Hubbard site and could not find the 30v 8.5 amp power supply. Did you contact them by phone or e-mail.I think I am going to start a build next week, and so far want to follow your lead!:wave:

-

02-15-2011, 04:19 AM #20

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Their 30v 8.5amp power supply is not listed... Send them an email... I will PM you the email address!... Thanks for the kind words!

I just finished the 3rd coat of paint on the table.... tomorrow... I will flip it over and do a few coats from under.... as all the paint i have put on has been shooting it from above and shooting up on the underside... I dont want it to rust and i would like it to stay as clean as i can... and rusty metal is not clean!...

Similar Threads

-

New Free CNC Router Plans 12" X 11" x 4", Build for $220 or $105

By Modular CNC in forum Open Source CNC Machine DesignsReplies: 1Last Post: 11-25-2013, 12:57 PM -

very large 3-axis 72"-55" project starting

By haylspa in forum Benchtop MachinesReplies: 7Last Post: 06-05-2013, 09:52 PM -

Table top MDF build - "The Home de-bot"

By JohnnyVegas in forum CNC Wood Router Project LogReplies: 31Last Post: 06-25-2011, 01:55 AM -

Anyone bought a "plasmabot"???... Feedback???

By winegar in forum Want To Buy...Need help!Replies: 5Last Post: 02-02-2011, 04:41 AM -

First build 8020 60"x24"x5" Board Shaper

By dlyork in forum DIY CNC Router Table MachinesReplies: 18Last Post: 09-07-2010, 02:32 PM

Reply With Quote

Reply With Quote