good job i see you improve your cutting lines a lot. Did you find out what was the problem on the beginning of the project?

Results 241 to 260 of 341

-

05-04-2011, 03:20 PM #241

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

05-04-2011, 03:31 PM #242

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Thanks!.... No not really... I'm getting perfect cuts, cutting @ 100ipm or slower... That is what these were cut at.... I had a friend come over the other day to check out my setup.... He has a very large one at a machine shop somewhere in Fla, told him of my problems at higher speeds... He checked it out and said it has to be in the software somewhere or perhaps the driver-board.... as if you pull the pendent up and run the X-axis and then the Y-axis... the Y is noticeable smoother..... and i seem to be only getting the "ripple" effect on one axis as well.....

I'm ordering some new Cable Track that I can run my plasma torch lead inside here in a few days, and I may be ordering a Machine Torch end as well and get away from this hand held unit, and redesigning my Floating torch mount too....

If you speed her up to 200+ipm you can visually see it shimmy and the end of peaks, however there are NO play in anything.... We are figuring that it has to be software related somewhere!.... Till then.... 100ipm, I've got too much on my plate to be digging too deep right now.... :-D

-

05-09-2011, 10:53 PM #243

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Guys... I really need help finding a way to put Text in my .dxf files... I have, but I suck at Autocad... and I'm currently using emachineshop for there free .dxf creator... I can make anything on there... but making a dang sign... I cant make any text!....

-

05-09-2011, 11:35 PM #244

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I was JUST dealing with this....and found this old post. Little program, and so far works great: http://www.cnczone.com/forums/autode...gram_turn.html

Carl

-

05-10-2011, 11:56 AM #245

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Do a search for DESKENGRAVE its free does text with arcs etc. works for me and the price is right

Mike

-

05-10-2011, 12:03 PM #246

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Thanks guys!... I will check those out today.....

-

05-10-2011, 12:53 PM #247

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I just got started moving my machine (drawing with a marker...) and I noticed some ripples at higher speeds. Looks to me like the IVTAAG rail flexing torsionally when the machine makes direction changes. After I get things more dialed in, I may look into options for increasing torsional rigidity.

You can check it out easily just by pushing on or slapping your Z axis and watch it vibrate.

Here's video of mine: this is at 80ipm, but at 160ipm you could see the ripples on the M when it reversed direction.

[nomedia="http://www.youtube.com/watch?v=NlrL5OZSHGw"]YouTube - MVI 2382[/nomedia]Carl

-

05-10-2011, 02:53 PM #248

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 0

winegar just have to say thanks again for the great thread - I constantly find myself returning for reference :cheers:

Today is supposed to be the day I finally get my Y axis rails - waiting for the call...

I also need to actually buy a plasma cutter today - I am going for the Everlast brand. They have new units which they say include a CNC port in the back and now use machine torches as well.

Question for those in the know just how much work is it to get a high frequency unit working. They have a blowback type 50A and a 70A HF on special for almost the same price. I am using shielded cabling but do not have a ground rod in the garage. Is it really required? Can I piggyback off the grounding in the basement about 10-15 ft away or must the ground point be as close as possible?

Thanks in advance

-

05-10-2011, 02:56 PM #249

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 0

-

05-10-2011, 04:17 PM #250

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

05-10-2011, 06:10 PM #251

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 0

cool thanks!

Also just got call for my rails - WOOT:banana:

-

05-10-2011, 08:53 PM #252

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I Lean.... So your gantry is flexing some when making direction changes?.... That might be my problem as well... If I take my hand and try to move it... It does not really move very easily... but when watching it @200ipm I can see my torch tip wiggle and that is the problem I have had... I might run a 1/8" piece of cold rolled on the underside of my gantry and strengthen it and keep it from deflecting... What have you come up with?....

I though it was in my motor tuning up until i seen your post and watched mine!... :-D.... Should be a simple fix though!.... Let me know what you are thinking!

-

05-10-2011, 08:59 PM #253

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Yes, if I grab it at the top (the motor for the Z axis) it's fairly easy to get it to twist a bit. It's harder toward the ends, easier in the middle naturally. In fact, I'll bet if you cut the same part in the middle of your table, and again over on a far side, you'd see a difference in the amount of "wiggle".

I've come up with nothing so far beyond brainstorms. I'm thinking increasing torsional rigidity will be more a function of the size of whatever you add, so maybe a 1.5" aluminum box tube bolted under the existing gantry rail would help.

I'm gonna wait until I actually cut some metal first, before I start modifying it more. Carl

Carl

-

05-11-2011, 04:22 AM #254

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

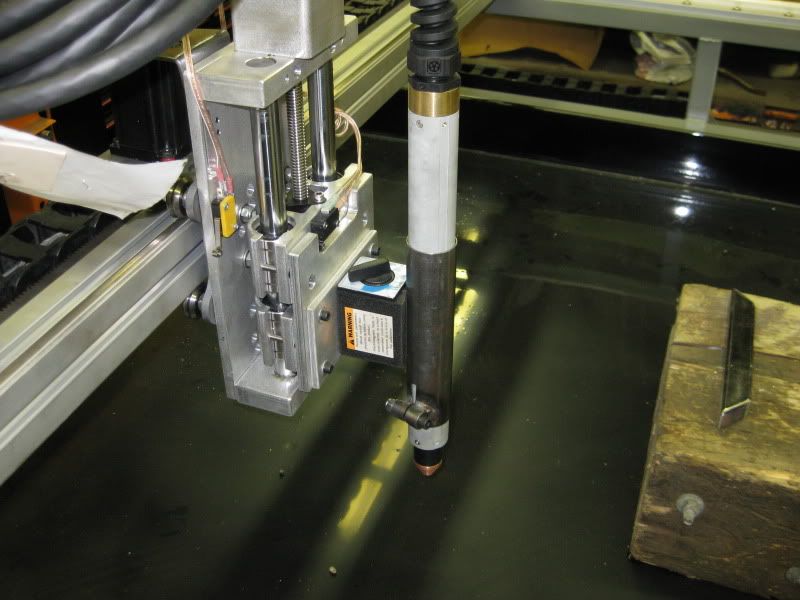

Here's a pic of how I did my magnetic breakaway mount for the torch. It seems like it will work, but since I have yet to use it I can't be sure.

Carl

Carl

-

05-11-2011, 01:36 PM #255

Registered

Registered

- Join Date

- May 2007

- Posts

- 250

Floating head

Floating head

Carl,

Look well for the floating head. I guess you are using the thermal dynamic plasma cutter. Do you use THC for your machine ?

Mongkol

-

05-11-2011, 04:37 PM #256

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

-

05-11-2011, 08:46 PM #257

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I lean,

It looks to me like your pen holder is not holding the pin tight. If you watch the top of the holder the washers and bolt seen to move around front back side to side.

Could this be your problem?

Winegar,

I have run my machine (a clone of yours) except the z axis which I home brewed at 350 ipm and I do not get the wiggle. I will be cutting my slats at 350 ipm this weekend and will try to post pictures.

-

05-12-2011, 01:43 AM #258

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

I know the marker moves around--but I don't care, I didn't really intend it to draw pictures.

The wiggle is visible in the Z axis separate from the pen's motion.

Carl

The wiggle is visible in the Z axis separate from the pen's motion.

Carl

-

05-12-2011, 02:50 AM #259

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

too tired to play today.... 2nd day of the new job..... I have me a job running cnc robot welder now.... about the size of a short bus!.... should be taking my welding cert next week i hope... big pay bump!... Will make a few parts tomorrow and check about either doing some tubing or maybe a 1/4" alum plate on the bottom of the rail... we will see... They have so much fun toys at my new job.. wish i could use some of it for just a day!... I would stamp me out a water tray in one piece and make some pretty stuff!... lol... later guys!

-

05-13-2011, 01:27 AM #260

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 0

Cut some 14ga stainless today... Not impressed at all.... Is there some trick to cutting stainless?.... Lines were not clean like the reg steel i have been cutting.... Took a lot to clean it up to where i would even give it away!......Anyone?

Similar Threads

-

New Free CNC Router Plans 12" X 11" x 4", Build for $220 or $105

By Modular CNC in forum Open Source CNC Machine DesignsReplies: 1Last Post: 11-25-2013, 12:57 PM -

very large 3-axis 72"-55" project starting

By haylspa in forum Benchtop MachinesReplies: 7Last Post: 06-05-2013, 09:52 PM -

Table top MDF build - "The Home de-bot"

By JohnnyVegas in forum CNC Wood Router Project LogReplies: 31Last Post: 06-25-2011, 01:55 AM -

Anyone bought a "plasmabot"???... Feedback???

By winegar in forum Want To Buy...Need help!Replies: 5Last Post: 02-02-2011, 04:41 AM -

First build 8020 60"x24"x5" Board Shaper

By dlyork in forum DIY CNC Router Table MachinesReplies: 18Last Post: 09-07-2010, 02:32 PM

Reply With Quote

Reply With Quote