I want to build a CNC Mill.

This is born out of, I like the idea of building my own, but also nothing really seems to exist that fits my own personal needs.

As I have read quite a few threads regarding self-built lathe & mill projects on here, I thought I'd ask the forum what works and does not work, hoping to tape into the combined knowledge & experience.

I have looked at used CNC mills, but they are normally way too big to fit into my machine shop, the power supply needed far exceeds the supply I have available, those that do meet my size & power supply requirements are way too expensive.

So, I looked at the benchtop models, whilst price is OKish, the build quality is not upto my standards, or just not heavy enough.

After a year of searching, for my ideal machine I have decided it does not exist.

Seeing the projects on here has filled me with inspiration, and admiration for what has been achieved.

So firstly, what works for a fabricated construction, has there been any disasters that should avoided?

Cheers

Chris

Results 1 to 12 of 12

-

03-05-2011, 11:21 AM #1

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Suggestions wanted for mill project

-

03-06-2011, 12:00 AM #2

Member

Member

- Join Date

- Apr 2004

- Posts

- 5737

What are you planning to do with it?

Is building the mill itself as far as your thoughts have taken you, or have you considered the potential use of the thing? For heavy metal cutting, you need maximum mass and rigidity; for lighter cuts in softer materials it's less important. What size parts do you want to make? From what materials? Will this have a 4th axis, 5th axis, or just 3 axes? I imagine there are plenty of disasters to be avoided, but starting with a solid plan of action will help with that.

I'm not sure that your first consideration should be the power supply you happen to have on hand. I'd say start from first principles, and get the power supply you actually need to accomplish the work you want to do (unless by "power supply" you're meaning your mains current, which you'll either have to live with or move.)

Andrew Werby

ComputerSculpture.com — Home Page for Discount Hardware & Software

-

03-06-2011, 09:01 AM #3

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

I do need heavy metal cutting, so I plan to build it has heavy and as rigid as I possibly can. So to begin with I was thinking a minimum of 6mm wall thickness, if I go with a welded structure using plate, and use a more appropriately heavy section where it's needed. (I'll hopefully have the drawings of the column finished this evening so I'll post it on here for comments)

As regards to axis travel some where in the region of x: 600mm Y:400mm Z:500mm. my needs are mainly producing parts for my own agricultural needs, but also for doing the jobs other people bring in to me (which can be anything, the mill I have right now has meant I've had to turn away a lot of work).

3 axis for the moment, i like the idea of adding a 4 & 5 axis later for my own projects, at least.

Unfortunately I do mean mains supply, which is 240V 13A, so I'll have to live with that I'm afraid. Unless anyone knows of a way of getting a more powerful motor than 3HP to run on 13A?

Thanks for the comments

-

03-06-2011, 07:29 PM #4

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 0

check following link

• Bekijk onderwerp - Bouwverslag stalen CNC portaalfrees

The buildthread is written in Dutch but a couple of pictures says more than thousand words.

-

03-06-2011, 07:40 PM #5

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Thanks for the link.

However, I can't see the images due to not being registered on that forum.

I would register, but as I don't speak Dutch, i can't figure out how to register.

-

03-06-2011, 08:25 PM #6

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Woohoo, figured it out :banana:

That was definitely worth the effort.

yup those pictures, did paint a thousand words

Many thanks T.W.O

-

03-09-2011, 12:09 AM #7

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

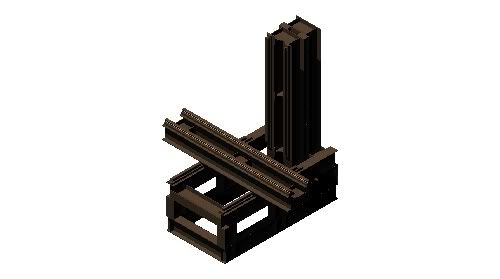

Took a little longer than I thought, especially after looking at the link T.W.O posted.

Sorry if the rendering is crap, I don't normally render to file.

comments?

-

03-09-2011, 12:38 AM #8

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 485

It looks like your using 'C' channel for your frame work. You will not be happy with that in the end, 'C' channel is not very stable, it will twist. For the same or just a little more money you will get a much stiffer frame by going with square or rectangular tubing.

A square/rectangle section is much stiffer than the same amount of steel in a 'C' channel.

-

03-09-2011, 12:52 AM #9

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Yeah, sorry the rendering is not that good, it's I section, Rolled Steel Joists, dimensions 152x89mm 6mm thickness.

I'm hoping with the extra square section I'm going to add to it, will give a heavy & rigid structure, overall dimensions are 1.8m high, 1.4m deep and 1.5m wide. Mass, so far approx. 340Kg

-

03-13-2011, 10:40 AM #10

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

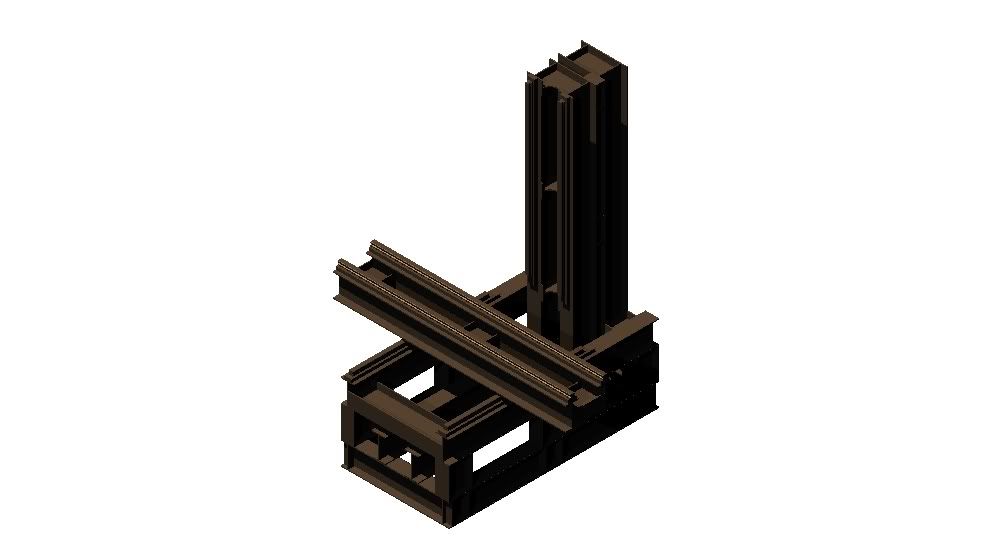

Here's a bigger rendering, I hope it's a little clearer

Right now all I want to do is get the design right, I don't have the time to build it yet.

Besides, I got yo get my Lathe working first! But that's going to have to be another thread.

-

03-15-2011, 06:56 AM #11

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 0

Welding

Hello

Those I beams are not flat enough to bolt your linear bearings on, so they need to be milled. The Z-axis need to be complete square on your Y-axis and if you gonna weld the structure together there will be a lot of stress in the structure, so you must stress relieve it in a oven.

I have also plans to make a steel cutting mill. My plan is to build it with 20mm

flat steel. I think it will be easyer to accomplisch. I'm gonna weld 2 parts and bolt them together after milling them flat and square (see pictures).

I hope my English is readable

greetings

-

03-15-2011, 08:53 AM #12

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Your idea is pretty much the same as my original idea, although I was not going to use 20mm steel.

I was going to use 12mm but have a lot more structure to it.

I am going to have to agree with you regards the stresses introduced into the structure with the design I've posted.

But as regards to the Linear rails, they are going to be bolted to a 50x20mm flat steel, which in turn is welded on to the "I" section. Thus, no need to mill the "I" sections.

I was looking at using some box section, as I can get it in anything upto 300x300mm 12.5mm wall. That would give a very rigid structure with minimal welding and little or no post heat treatment.

I'll post some pics later when I get a chance to get them done.

And regards to your English, it's very good, and a pleasure conversing with you.

Chris

Similar Threads

-

Suggestions for a mill

By TheGreenMachine in forum Benchtop MachinesReplies: 5Last Post: 05-19-2010, 09:21 AM -

Mill SUggestions

By ajm11 in forum Benchtop MachinesReplies: 5Last Post: 04-08-2010, 06:07 AM -

Suggestions wanted.

By manolo74 in forum DIY CNC Router Table MachinesReplies: 15Last Post: 08-18-2009, 03:52 AM -

new to cnc, about to buy a mill, need cam suggestions.

By e343mg in forum Uncategorised CAM DiscussionReplies: 2Last Post: 07-07-2009, 04:43 AM -

Newbie Vacuum Forming Table wanted Suggestions

By darticus in forum Vacuum forming, Thermoforming etcReplies: 1Last Post: 07-06-2008, 04:04 PM

Reply With Quote

Reply With Quote