Okay, So I'm going to be doing my first project on my new CNC table in about a week.. There'll be another project I'm doing concurrently, but I'll start a separate thread for that...

This first one will be to build kitchen style cabinets from 23/32" furniture grade plywood... Will be building oak face frames the old fashioned way... doors and drawers to be made later, hopefully with the help of this table...

I currently have only Cut 2D, but plan to have V Carve Pro within a week...

I have a couple questions, one area of concern being 'methods' and the other being 'tools'..

1) There is no real place to clamp this down as it is going to be cut from full 4' x 8' sheets of plywood.. That stuff is never flat and needs to be clamped... I'd like suggestions from those of you who do cabinets with their CNC rigs regarding how to approach this... If I were to use V Carve Pro's nesting, does it allow for creating 'extra' space between components so that hold down screws can be used?

Should I cut all my dados first and then pocket some hold down holes in the bottom of the dado? The backs of the dados will be hidden, from view so that's not a huge deal, but I'd rather not have to go that route...

If I were to use common cuts for two edges of two different cabinet pieces, what size tabs are typical.. I am concerned about having these tabs where those edges are going to be mating surfaces inside of dados...

2) I plan to upgrade in a couple months to a slightly bigger router, but currently use a Porter Cable 690... I would like to consider using a roughing bit and then a finishing bit to cut these panels.. but I really don't know if that's the best way to go or not, nor which types to chose and what size...

I currently have noway to run the router other than at full blast, and unfortunately, I will have cut all or most of the cabinets by the time I can even afford to order a S-PID, much less receive it and finish installing it...

I can't afford to go 'cadillac' on the bits yet, but I don't want to buy crap either...

So I guess I'm asking for some advice here too..

Thanks,

Mark

:cheers:

Thread: First Project.. Need advice

Results 1 to 17 of 17

-

05-30-2011, 09:14 PM #1

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

First Project.. Need advice

-

05-31-2011, 01:32 AM #2

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 211

Others may disagree with me, but. . . .

I would NOT use nesting to do this for the following reason:

Nesting places parts where IT wants to put them. In other words, you would have to do some real careful figuring to place those screw holes.

It would be much simpler for you to load the panel then TELL vcarve where you want it placed. Load the next panel and place that one, insuring you leave the space for the screw on the sheet.

Another hint here, if you are going to use screws, see if you can find some solid brass wood screws, they cost a bit more, but they are a lot easier on your router bit if you screw up. Sometimes you can even find them in aluminum.

I wasn't really sure what you were asking in your second question?

-

05-31-2011, 02:11 AM #3

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Regarding Q#2.. I currently have a couple 1/4" upspiral bits, and the usual plethora of standard router bits...

I'm wondering if there is a better way to go than using the upspirals for the edges, and standard router straight bits for the dados..

I saw someone post about roughing bits and finshing bits.. this sounds like the hot ticket.. but I don't really know much about CNC bits in general yet..

I'm currently cutting at about 60-80 ipm in four passes for the 3/4" plywood.. But I'm thinking that with these bits I might be able to cut faster, or at least in less passes..

But I'm not entirely sure about the veracity of this, or which ones I should get if true..

-

05-31-2011, 08:50 AM #4

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 229

Here's another viewpoint:

with nesting (we use ER), you can set the margin from the edge of the sheet, and the gap between the pieces, before you let it start to figure it out.

Then once you have the layout it devised, you can go and manually place some screwholes on the image in your monitor, and then send the router off to predrill them say halfway through ay 1/8" diam.

Then tek-screw them down through these holes which you now know will be clear of any cuts.

Then cut the nested parts you wanted. A word of advice- don't cut right through in one pass, even with bridges- split it into two passes at least, until you really know what you're doing-and even then still consider doing stuff like that in two passes.

That brass screws idea is a good one - I ruined a couple of great Onsrud tapered ballnose bits due to a it hitting hard phillipshead tekscrew or two that I thought was further away from the business end than it actually was...

-

05-31-2011, 12:47 PM #5

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 211

Here are my thoughts on cutting out plywood using a router.

Ask yourself a couple of questions:

Does the layout demand that you use a 1/4 inch bit to cut the parts out? In other words, do you have scrap leftover that would allow you to space the parts farther apart?

Can your machine handle higher feedrates than 60-80 IPM?

If the answer to these questions is yes, then you might want to think about using a 1/2 or 3/8 bit. CNC routing has some things in common with machine shop work. One of the basic rules is that you use the largest tool possible to get the job done. There are a lot of reasons, the first is that larger tools are more rigid. The second is that you can cut faster with them. The third is that you can cut deeper in a single pass with them. You will also find that a 1/2 inch straight flute bit has more chip clearance than a 1/4 inch bit. The straight flute results in less tearout at the surface than an upcut spiral.

Interestingly, a lot of 1/2 inch bits are available that are not solid carbide, so they are about the same price as a solid carbide 1/4 inch bit.

Most of the cabinet work I have done has dadoes that are slightly less than 3/4, so a 1/2 inch bit works really well.

By the way, you mentioned "CNC Router Bits", well, with a few exceptions, there is really no such thing. The bits used in CNC machines are the same bits used in a hand held router. What is interesting is that because of the machine you can climb cut with them all day long, which you would not dare do with a hand held router. Because of the controlled, consistent cutting of a CNC machine you can push a router bit much faster than you could by hand.

-

05-31-2011, 02:14 PM #6

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 67

Consider a vacuum table

We have machined aluminum parts using a vacuum table it is something you can easily build and as long as your parts have enough surface area they will hold in place easily. With this you do not have to worry about screws or clamps to get in the way. It is flat piece of wood or aluminum with slots milled in it all connected in a crisscross pattern and a hole to connect a vacuum pump. You may not think it will hold but do the calculations at 16.4 something PSI pressing down on the part which is what you end up with if you have a good vacuum there is a whole lot of force holding your parts in place. Another advantage is it pulls the part down flat so if you have cuts that do not go through they will end up a uniform depth. You can pick up a vacuum pump for abut $300 maybe less if you can find a used one and you can make the table yourself. Also you can use this for many different projects if you purchase some sealing molding, you do not want any spaces open where the parts are not sitting, all you need to do is simply press the molding into any areas not covered by your work piece. So look in Mcmaster carr for a molding and make your slots the correct size and depth for the molding to just stick up above the surface of the table. The molding must be compliant enough to compress when the vacuum is applied. If you use wood for the table I think you may have to seal it with something depending on it's porosity.

-

05-31-2011, 03:02 PM #7

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

I thought that there were a lot of bits that were "CNC Only" in that they were not anti-kickback... Amana has a whole section for CNC bits...

This was basically what I was asking, is should I go with the larger bits? My machine can push as fast as the router will cut.. But I don't know what a 690 will handle... I have used it by hand to plunge cut using a bushing/template with a 1/2" x 2" standard straight bit though (2 passes in 3/4" plywood), but I don't know if these roughing bits and what not require more power...

I was wondering what the difference is between climb-cutting and conventional... I understand that it means pushing the other direction.. but what advantage is there in that? Why would I want to do that? And is that something that can be done with all bits?

-

05-31-2011, 03:55 PM #8

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 67

Climb cutting

If you have backlash in your system I do not reccomend you try climb cutting, climb cutting pulls on the entire spindle assembly and if there is backlash you will get poor results. You must have a good rigid setup with minimal backlash in your screws for climb cutting to be effective. You do not need to use a router bit you can use any standard end mill or cutting tool try a left hand spiral right hand cut tool it will tend to push the work down and it will also tend to reduce the pulling affect you get when you climb cut, any cutting tool supply place will have them. I would use a 2 or 3 flute tool to allow room for chips and a high spiral if you can get it. Climb cutting in general gives a better finish and longer tool life, less rubbing. In wood it is probably not as much of an issue but in steel or aluminum we climb cut when ever possible.

-

05-31-2011, 04:24 PM #9

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

My system is fairly rigid.. R&P.. 3060 gantry 1530 X rails, 3 axis 4 motor NEMA34.. The only screw I have is on the Z axis... It's a 5 start...

But I have not measured for backlash...

Can Climb cutting be done with 'any' bit? 2 flute straight plunge bits? Insert Bits? Upspiral, downspiral, LH spiral, RH spiral, compression? Ogees, coves, etc?

-

05-31-2011, 04:43 PM #10

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Yes, you can climb cut with any bit.

We cut 3/4" melamine everyday, and I've found that climb cutting gave us a poorer cut, and shorter tool life when cutting at high speeds (700+ipm)

For your situation, I'd use regular 2 flute carbide tipped 1/2" straight bits, and make two passes. Try 200-300ipm. You can get them for about $10-12 each.

At the high rpm's you're using, you can't cut fast enough to take advantage of spiral bits, and you'll dull them quickly.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

05-31-2011, 04:48 PM #11

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 67

Yes any tool will work

Yes you can climb cut with any tool some will work better than others it really depends on a lot of factors. How rigid your machine is, how much backlash you have in the screws, how well your part is held down, how thin of a section you are cutting. This is where a tool with a high helix flute may help particularly a left hand spiral right hand cut. A tool with a right hand spiral right hand cut tends to lift the work and this can be an issue if your clamps are not very close to the cutting area and your material is thin. You would be better off with a straight flute tool in that case if you can not get the LH spiral but a straight flute tool is a hard cutting tool you will get a lot more vibration than you would from a spiral flute tool.

There are hundreds and hundreds of different tool configurations you can play with they are called end mills in the machining industry do a search and you will see what I mean. Try going on line to a place like MSC you have a ton of choices. You will probably find that you will pay far less for an end mill than you will for a tool that is being sold as a "router bit" to the general public. For example my local supplier offers 2 and 3 flute solid carbide endmills 1/4 inch diameter for $12.50 ea. I also highly disagree with the statement that you will dull a spiral flute tool out quickly I run 60 degree helix tools at 10,000 RPM through steel, aluminum and glass filled plastics on a regular basis and they far outlast a standard 20 degree helix tool and a straight flute tool would fail very quickly and give me horrible results under the same circumstances. You have to look into the new tools and coatings available that most in the hobby industry may not even be aware of, coatings like titanium carbonitride these coatings can greatly increase your tool life. Micrograin carbide is another option, as I said there are hundreds and hundreds of different options and combinations available to you, it may be a matter of experimenting with your machine to see what gives the best results. All machines and all jobs are not the same, what does not work for one guy may work perfect for you, you have to go by your own tests to get the best results for your circumstances.

-

05-31-2011, 09:23 PM #12

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

These are some of the straight bits I have... One of them is broken so ignore that one... I noticed it after I took the picture, but an identical one to it is next to it still in the protective coating...

Anyways, there is a brand new 1/4" straight plunge bit, a 1/2" x 2" straight plunge bit, a 1/2" x 3/4" straight plunge bit, and a 1" straight plunge bit...

Are the 1/2" bits a good choice for cutting cabinets from plywood? If so, I could use them to cut the dados too without changing bits...

I'm also wondering if the 1" bit is suitable for surfacing the table, or if I should get something bigger... It'd be nice if I didn't have to at this time though.. I'd rather spend money on other general use bits...

If I were to cut with the 1/2" bits, would 100 IPM be a decent speed? Or should I push it a little faster?

I don't want to push the speed to much at this time though, as I'm concerned about rigidity of the table in it's wooden based version... When I get the steel base done I can go nuts.. 'Or' I could reduce the acceleration and deceleration... but I think that might affect accuracy...

What do you guys typically have your motor accel/decel configs set to with similar tables? (80/20 based CNCRP R&P 4' x 8' NEMA 34)

-

05-31-2011, 09:32 PM #13

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

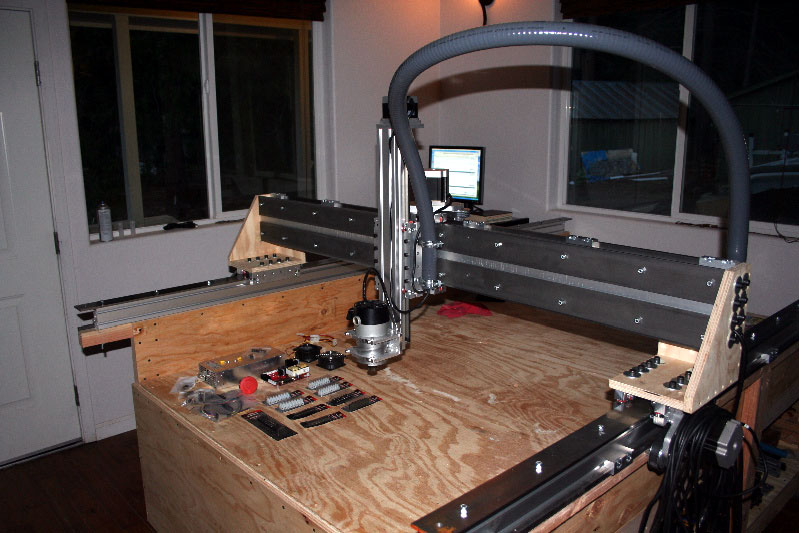

Here's the table for those of you who haven't been following the build, so that you'll know what I'm working with..

-

05-31-2011, 10:49 PM #14

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Those bits will work fine. However, try to use the shortest ones possible. You'll get better cuts. I'd never use those longer ones, unless you absolutely need that much depth, or they're the only ones you have. The shorter the bit, the more rigidity you'll have, resulting in cleaner cuts.

Did you see my previous post? Sure, you can cut at 100ipm, but the slower you cut, the faster the tool will dull.If I were to cut with the 1/2" bits, would 100 IPM be a decent speed? Or should I push it a little faster?Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

05-31-2011, 11:04 PM #15

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

(chair)(nuts)(wedge)

Arghh..arkka-frakka*#!-_*&*%$ akka saraffra daggoet...

Just snapped another 1/4" upspiral!

Turned off the router for a minute while I loaded the next program so the vacuum could work better in the interim.. Ran the program without starting the router back up.. didn't notice because the vac is dang loud!

I'll be able to automate this from Mach 3 at some point right? Use a relay to automatically start the router when the program is run? I hope!

(chair)

Need to get that e-stop hooked up too!

-

05-31-2011, 11:08 PM #16

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

The Super-PID will do it without needing a relay.I'll be able to automate this from Mach 3 at some point right? Use a relay to automatically start the router when the program is run? I hope!Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-01-2011, 12:09 AM #17

Registered

Registered

- Join Date

- Jul 2010

- Posts

- 1328

Excellent! I can then save my two relays for the vacuum and light...

This snapping bits crap has gotta go! LOL

(and it's way too easy to do.. the less I gotta keep track of the better)

This months funds are gonna be chewed up getting V Carve Pro and a few bits...

So if I can get through the month without destroying anymore bits I'll be good.. then I can get the S-PID

Similar Threads

-

General advice and equipment advice

By GeorgiaRaised85 in forum Uncategorised MetalWorking MachinesReplies: 6Last Post: 03-28-2010, 11:00 AM -

newb needs advice on pic project

By anilam in forum PIC Programing / DesignReplies: 2Last Post: 11-10-2009, 08:39 AM -

Need advice in my project

By elchip in forum UHU Servo ControllersReplies: 1Last Post: 11-01-2009, 12:15 AM -

Need motor advice for a project...

By kentrob11 in forum CNC Machine Related ElectronicsReplies: 0Last Post: 03-21-2008, 03:05 PM -

Need some advice on my project

By sigipa in forum Mechanical Calculations/Engineering DesignReplies: 9Last Post: 09-16-2007, 05:43 PM

Reply With Quote

Reply With Quote