Hi- My name is Christian.

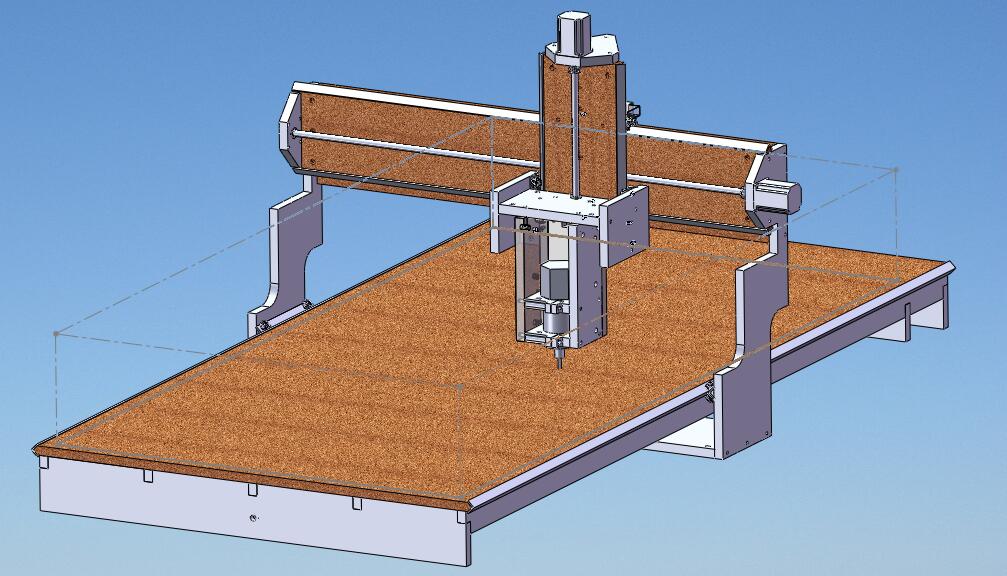

I am announcing my :bs:>>>DIY CNC Router<<<:bs:

The link is my detailed blog regarding this build

Build: HobbyCNC-electronics based router.

Material: MDF 0.75"

Parts- cut out with table saw and post processed.

Design Basis: WoodworkerB's Blog

Actual size: 80" x 60" x 42"

Working size: 72" x 36" x 9"

CNC Design Tool: SolidWorks

Motors: 200oz-in 1.8 degree (200spr)

Lead Screws: 2-start 5tpi

Resolution: 0.001"

Machine Control: Mach3

Part design: SolidWorks exported as DXF

Plans will be available (someday, if there is interest)

Completion target date: 07/2011 (?)

I am a design engineer, I work in SolidWorks, I own and operate a PlasmaCAM CNC plasma torch (w Miller 375 Xtreme inverter 27a). I built the HobbyCNC chopper stepper driver kit, and have tested the motors with Mach3 and appears to operate nominally.

Feel free to get ideas for your own, or copy what I have done.

Visit my ongoing construction blog for this project and leave comments or whatever here.

Enjoy-

-Thanks

-Christian

:cheers:

Results 1 to 4 of 4

-

06-01-2011, 02:33 AM #1

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 25

Brilliant Design 72"x36"x9" CNC Router (HobbyCNC based)

Brilliant Design 72"x36"x9" CNC Router (HobbyCNC based)

-

06-01-2011, 03:05 AM #2

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 853

Hi Christian;

That is quite a large machine! Are the sides of the gantry going to be MDF or metal? Either way, I would think that you are going to have some sway because of the height. Plus, the gantry sides become very narrow just below the Y stepper motor. Unless there is a very good reason for this, this looks like a weak point in the structure.

Good luck!

-

06-01-2011, 05:11 AM #3

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 25

Paul-

WoodworkerB's design did not allow the carriage to move past the gantry sides. So, as I designed, one of my criteria was to allow the gantry track to let the router bit center go to within ~1" of the sides of the table, to be able to reap the full width of the table. I know that this is a weak point, so I will use the CNC plasma cutter to create metal plates that will be mounted on the outsides with several bolts above and below to attach thru the gantry faces-kind of an exaggerated 'C' affair probably of 0.125"(?) Aluminum. And I wanted to have a fairly large table to be able to fabricate skins for the CriCri aircraft I am building.

There is also a 2nd y-axis stabilizing cross-member behind the gantry track that is not visible, which should reduce(?) Y wobble.

Thanks for the comment.

-Christian

-

06-01-2011, 05:14 AM #4

Registered

Registered

- Join Date

- Dec 2007

- Posts

- 25

Similar Threads

-

New Free CNC Router Plans 12" X 11" x 4", Build for $220 or $105

By Modular CNC in forum Open Source CNC Machine DesignsReplies: 1Last Post: 11-25-2013, 12:57 PM -

"low end" HF Spindle or "high end" router for about $1000?

By biomed_eng in forum DIY CNC Router Table MachinesReplies: 14Last Post: 01-06-2012, 07:15 AM -

new "small size" benchtop cnc mill based on weiss wmd16v

By ihavenofish in forum Benchtop MachinesReplies: 71Last Post: 08-01-2011, 04:01 AM -

Igus W chain driven router design 32"x82"

By chrismp in forum DIY CNC Router Table MachinesReplies: 3Last Post: 09-26-2010, 05:38 AM -

"motor steps per resolution" and "driver microstepping" settings

By margni74 in forum LinuxCNC (formerly EMC2)Replies: 9Last Post: 10-24-2009, 08:33 AM

Reply With Quote

Reply With Quote