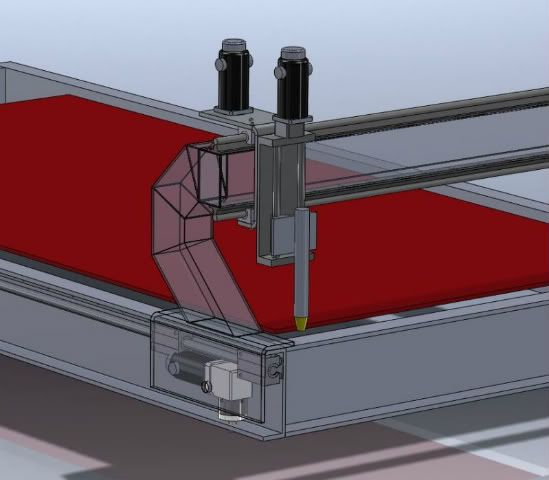

Just thought I would post up the 5th incarnation of the gantry design for our 10 x 5 plasma / router table.

The main frame is 250 x 75 alloy channel as drawn but needs to be slightly deeper to clear the drive pinion on the gearbox, Im hoping we can find a supplier that does 280 or similar to save re-designing the linear setup.

The gantry runs on twin INA re-circulating ball units running on 25 shafts supported by T extrusion. Motors are Toms 34 Servos running through 8:1 reduction right angle gearboxes to a approx 50dia (to be confirmed) pinion driving on 2.5 module rack. I am estimating 2500 ipm rapids (again depending on finalisation).

Gantry is from 6 x 4" alloy box, 12" Z axis from K2CNC with floating torch.

Take a look and feel free to comment......

Thread: 10 x 5 gantry design

Results 1 to 14 of 14

-

10-13-2011, 04:04 PM #1

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 44

10 x 5 gantry design

-

10-13-2011, 10:26 PM #2

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 303

Just my 2 cents;

I don't like the double 25mm shafts !! In CAD, it's an excellent design, but in the real world this type of setup will give you nothing but headaches. If those shafts were mounted on a machined and ground gantry it would be fine, but since you plan on mounting it on an aluminum (alloy) channel that was manufactured by extrusion, the channel will not be perfectly straight and true.

Another issue would be the 2500 IPM !! If you build something that fast, forget about putting a router on it because will have zero torque.

Like I said, just my opinion.

DanThe one that dies with the most tools, WINS !!

www.dantechfabricating.com

-

10-13-2011, 11:16 PM #3

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 44

Thanks for the input, points noted and will look at the max ipm again, I did think it may be a little high.

-

10-14-2011, 11:13 AM #4

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 0

I don't believe you can fit a pinion wheel of 50mm dia and mod2.5 rack in a 75mm deep channel with your current design. Also, are you certain your right angle box is to scale?

I do like the idea with the gantry mounted from the back like that instead of the sides, It'd help maximise usable space while minimising footprint. Which is obviously your main reason for a few of the features

-

10-14-2011, 12:55 PM #5

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 44

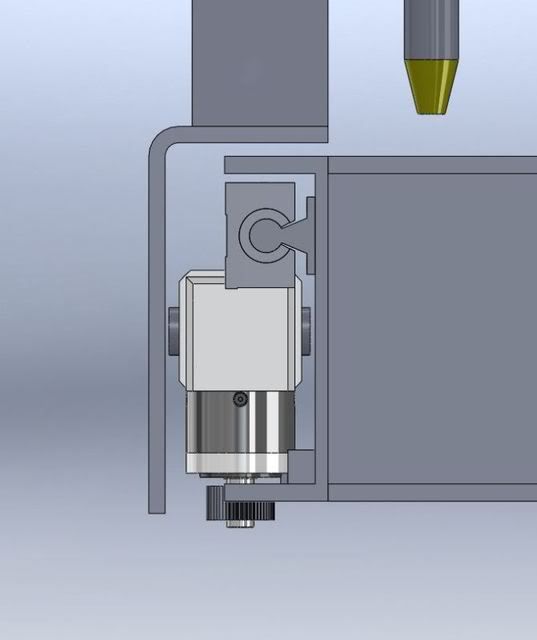

The pinion fits OK and all is drawn to scale. I`m not trying to keep the whole drive system inside the channel, just the rails so they are protected. You can see the clearance issue better in this picture..

Also the gearboxes havent been finalised as yet so its all still up in the air. I just wanted to get the general idea out there for comment.

Keep them coming !

-

10-14-2011, 01:25 PM #6

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 0

that's a better view. Must have it over tracked on the first one causing the illusion.

I do like the ideas but i think while you're thinking of channel, you'll be running around in circles with those components. A piece of angle over the top of the rails with the rails mounted on RHS would do the same job and at a lower price.

My father was an extrusion supplier here in Aus and has never heard of anything taller than 250mm in channel.

-

10-14-2011, 02:11 PM #7

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 44

I think you could be right on the channel. Once I have the final size of the gearbox, I will re evaluate where I am and what will fit.

-

10-17-2011, 03:11 PM #8

Member

Member

- Join Date

- Nov 2009

- Posts

- 159

Your side rails will not work in that configuration. The trucks you have there will pivot and you would be relying on the plane of the gantry to hold the "truck,gear" combo in the right plane. Typically those trucks dont work well on that kind of build unless your not relying on a pependicularity moment.

Now featuring Plasmaland online

-

10-17-2011, 07:44 PM #9

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 44

I have a feeling that revision No. 6 and 7 is on its way ! This is good though as it easy to re-design on the computer.Looks like I will be dumping the gearboxes and going to belt reduction aswell as getting good enough quality gearboxes at the right price is proving to be impossible .

Thanks for the input.

-

10-18-2011, 12:57 AM #10

Member

Member

- Join Date

- Nov 2009

- Posts

- 159

We have surplus #45 linear rail in different lengths if you want something solid.

Now featuring Plasmaland online

-

10-18-2011, 07:45 AM #11

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 44

Do you have a link ?

-

10-18-2011, 01:12 PM #12

Member

Member

- Join Date

- Nov 2009

- Posts

- 159

Sorry I dont its not what we use for production machines it came off an old build. Its the reciprocating needle style (heavy duty). I might be able to snap a pic for you and email it to you.

Now featuring Plasmaland online

-

10-18-2011, 04:31 PM #13

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 44

Please do.

-

10-18-2011, 06:18 PM #14

Member

Member

- Join Date

- Nov 2009

- Posts

- 159

I was told those rails are for domestic sale only. For international check here for linear rail

PlasmalandNow featuring Plasmaland online

Similar Threads

-

Gantry design

By Tailgunner in forum Mechanical Calculations/Engineering DesignReplies: 12Last Post: 10-02-2011, 08:50 PM -

Gantry: planning to design moving open gantry

By rdcd in forum Mechanical Calculations/Engineering DesignReplies: 0Last Post: 11-14-2009, 10:52 PM -

New design, gantry or something else

By Miguel- in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 01-26-2009, 10:33 AM -

GANTRY Design

By bert5604 in forum Waterjet General TopicsReplies: 3Last Post: 10-01-2007, 02:30 PM -

Gantry design???

By dmgdesigns in forum DIY CNC Router Table MachinesReplies: 1Last Post: 05-25-2004, 03:13 PM

Reply With Quote

Reply With Quote