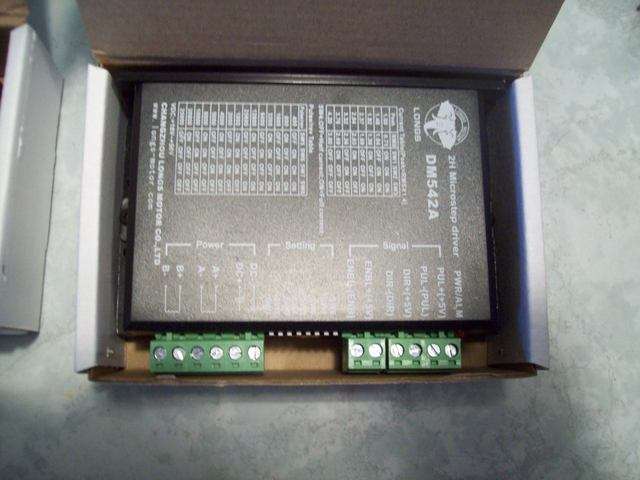

Hi, i would like to share my current build with you guys. It is pretty much DIY as it gets. It is for milling out foam blocks to create molds from. I ordered the 3 axis CNC kit from longs motors on Ebay, hopefully it is of descent quality. Im using the DIY gantry slide design with aluminum angles and skate bearings mounted on aluminum angles and threaded rod with a rod coupler to twist back and forth for each exis. It will be build mostly of 3/4" MDF wood. The over all cutting dimensions are

X-3'

Y-3'

Z-2.5'

Currently, I have mostly finished the stand and the base for the CNC machine. I received my 45 degree chamfer bit today so i can continue and start work on the slides. Im trying to save as much money as possible so i ordered it from ebay for 5 bucks instead of spending 18 dollars for one at a home improvement store. I actually could have saved 200 dollars and bought a 270 oz kit instead of the 425 but i guess its for the better since i can build a larger gantry next time and use the same CNC components.

Thread: Foam milling CNC machine build

Results 1 to 18 of 18

Hybrid View

-

02-22-2012, 11:21 PM #1

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 34

Foam milling CNC machine build

-

02-22-2012, 11:31 PM #2

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Looks good so far. You should be aware though that with the larger stepper motors, they will lose torque faster than the smaller stepper motors, so they're usually coupled with with multi-start ACME screws instead of threaded rod.

-

02-23-2012, 07:59 AM #3

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

looks good to me

. can you please explain the double panels on the sides? i assume those are the side panels, not front-back ones. rigidity, design?

. can you please explain the double panels on the sides? i assume those are the side panels, not front-back ones. rigidity, design?

best of luck!

edit: hope your mom/wife/whoever doesn't kill you for making it in the kitchen

-

02-24-2012, 12:12 AM #4

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 34

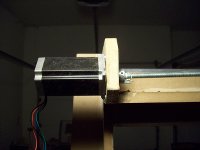

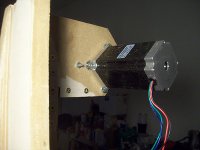

Hey guys, ive made a little progress today. Thought i was going to be able to create and assemble major parts for the X axis but ended up only getting the rails done. I spent 3 hours just getting the base and stand level, did alot of sanding on the part where the x axis rail will sit on so that when i screw in the rails it will be accurate and level. Got the rails cut, chamfered and glued the aluminum angle to the edges. Tomorrow i will be working on the slides.

-

02-24-2012, 12:19 AM #5

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 34

Yes those are the side panels, they will be supporting the x axis rails, so i doubled them up. Yea my mom is a cool lady, she let me pretty much have her garage where i do all of my cutting and building, im sure if it was any other woman i would be ball-less right now. im only building it indoors this time because the garage is too cold and unlevel for a project like this

-

02-24-2012, 11:09 AM #6

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

so i suppose this will be a moving gantry? IMO, good thinking on the side panels. i would maybe make them lower, closer to the base, but if the gantry risers are eliminated from the design (i suppose again), this seems like sturdy design. keep in mind one thing: if you are building this for foam shaping, make it a bit rigid-er. i was going for polystyrene cutting and milling, but liked it so much i just had to work on some MDF and HDPE. needless to say, i regretted not making it sturdier

nevertheless, i'll keep an eye on this thread! good luck!

-

02-24-2012, 10:58 PM #7

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 34

Did some work today. Got the side of the slides done.:cheers:

Also got a surprise in the mail, the CNC kit....only took 5 business days to get here

-

03-10-2012, 01:11 AM #8

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 34

sup young fellas. i havent updated u guys in a bit. since last update ive rebuilt the x axis slides so that it would work better, ive permanently mounted the y axis pillars and rail, built the y axis slide, and mounted the z axis rail to the y axis slide. Just alittle bit more work to be done and it will be done. I wasnt doing much work on it since last time since i was waiting for my shaft to rod couplers to come in and they finally did today. So i offically have everything i need to finish so i will be working hard for the next few days to get this done.

-

03-12-2012, 02:50 AM #9

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 34

-

03-17-2012, 07:01 AM #10

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 34

heres a video of the machine jogging. The only issue i am having right now is the backlash from the shaft and rod coupling.

[ame=http://www.youtube.com/watch?v=Z39RDk1J8w8]CNC Jogging. - YouTube[/ame]

-

03-17-2012, 07:45 AM #11

Member

Member

- Join Date

- Apr 2007

- Posts

- 1955

Neat. That is one impressive Z range.

Similar Threads

-

Build a workbench for a milling machine

By Vikash in forum Benchtop MachinesReplies: 30Last Post: 06-30-2012, 07:01 PM -

Want To Build 4-Axys DIY CNC Milling/Router Machine

By mesyin in forum DIY CNC Router Table MachinesReplies: 7Last Post: 05-29-2011, 09:34 PM -

My 3-axis foam milling machine

By Rhino3Master in forum CNC Wire Foam Cutter MachinesReplies: 7Last Post: 11-15-2009, 05:04 PM -

Foam & Wood milling machine

By perolalars in forum DIY CNC Router Table MachinesReplies: 0Last Post: 04-11-2007, 05:42 PM -

High Speed CMS FOAM 5-axis milling machine

By fairlane77089 in forum Hard / High Speed MachiningReplies: 4Last Post: 06-05-2006, 04:09 PM

Reply With Quote

Reply With Quote