Hello, Brian.

What type of aluminum Fractional T-Slottted profile did you use? Is it profile 10 (1020 and 2040) or profile 15 (1530(1530-Lite) and 3060)?

I'm using this as a reference:

80/20 Inc. - The Industrial Erector Set®

Sorry for my newbie question - this is my first experience with CNC and 8020 products.

Results 121 to 140 of 199

-

03-13-2013, 08:01 AM #121

- Join Date

- Mar 2013

- Posts

- 0

-

03-13-2013, 08:03 AM #122

- Join Date

- Mar 2013

- Posts

- 0

Hello, Brian.

What type of aluminum Fractional T-Slottted profile did you use? Is it profile 10 (1020 and 2040) or profile 15 (1530(1530-Lite) and 3060)?

Sorry for my newbie question - this is my first experience with CNC and 8020 products.

-

03-13-2013, 04:36 PM #123

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

Thank you very much for the comments! I hope to have a comprehensive post soon about the Initial Run soon as we now have a machine making its first cuts!! I have essentially had two 40 hour/week jobs the last couple months and look forward to having the time to finish some projects and post on the Zone!

The extrusions are fractional, I used 1530 for the 'bones' and 3060 for the gantry.

Brian

-

03-14-2013, 01:25 AM #124

- Join Date

- Mar 2013

- Posts

- 0

Brian, thank you for the clarification!

Is it possible to use dual RM2510 ballscrew for the Y-axis, RM2005 for the X-axis and RM1605 for Z-axis? (all from e-bay)

My concern is they have different diameter/lead values and "turn*curcuits" is also different. Does it mean that with one spin of a motor on Y th granty will travel further distance, than on axis X? Should i worry about this or it's a job for the Gecko540?

Thanks!

-

04-03-2013, 04:33 AM #125

Registered

Registered

- Join Date

- Sep 2009

- Posts

- 6

Did the Grunblau cnc kit die? Are there any from the first build for sale?

Did the Grunblau cnc kit die?

I've been trying to find out how to order one, but haven't had any response over the last 6 wks or so. For lack of any other info, I'm guessing this means it's dead. Does anyone know if there are any for sale from the original buyers?

If anyone has any updates, could you please post them? i would really, really like to order one from the second batch, but my budget cycle is going to close shortly and if i can't write a check shortly, i'll lose it forever. any info appreciated!

-rg

-

04-03-2013, 04:50 AM #126

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 265

Fanstic looking machine! I use denatured alcohol for milling aluminum. Works really well, at least as good as WD40. I like it much better than WD40 because it leaves the parts and machine clean and dry once it evaporates. Just vacuum the dry chips.

-

04-03-2013, 03:21 PM #127

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

Russ-

Check your email! The next run is extremely close! I will be announcing it very soon to all of those people who have emailed me. It seems as though I have somehow lost connection to this thread as I usually get a notice when someone replies. Likely due to the site revamp.

As far as updates, I will likely post them in this separate thread . I will still post updates as I come up with add-ons for my machine here.

Thank you very much for your interest!

Brian

-

04-03-2013, 03:22 PM #128

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

-

04-03-2013, 07:56 PM #129

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 265

A spray bottle works well. Not much is needed. Occasional spraying works. I use a thin tube to transfer the the alcohol from a pressurized bottle through the gantry to a nozzle that I position by the tool. I close the nozzle so that the alcohol comes out as drops a second or two apart. If I'm doing deep slots or critical work where the drops will never find their way to the tool, I increase the pressure so that there's a stream on the tool.

-

04-08-2013, 04:32 AM #130

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 4

Hi Brian,

On the Gantry you have a top pice and a bottom piece which runs under the table. Is it possible to run without the bottom piece should you wish to do dovetails or other through the table joinery?

-

04-08-2013, 03:23 PM #131

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

With a slight modification I imagine that is possible. If you were to do away with the bottom cross member and add two separate plates for the leadnuts to mount to and would be held by the upright brackets, you could have most of the table free for pass through work. I have no idea if this would affect rigidity as the dual drive does a lot to stiffen things up.

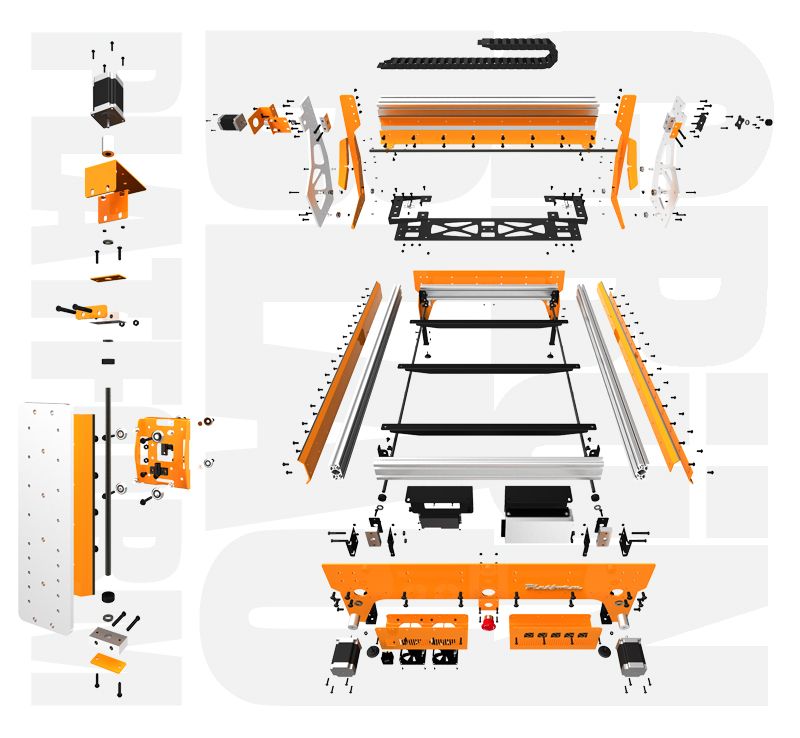

Essentially cutting out the two 'X'S on the black piece under the table in this picture....

-

04-11-2013, 03:21 AM #132

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 0

I started out running my t-slot length wise and changed it to short side so I can remove a section and do dovetails. The offset of the router is enough to clear a vertical drawer piece and cut both pins and tails at once. Unless you have some REALLY tall drawers. I also cut a slot in the table base below to clear the vertical. I plan to build a clamping piece much like a dovetail jib to hold the pieces with clamps.

Now if only work would stay out of the way. Steve

-

08-07-2013, 11:16 PM #133

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 83

Brian,

I added my name to your next run of Platform. In the mean while would you have time to post a basic dimensions sketch of the Platform CNC. I.E. foot print, height of the table, overall table size, cutting area X,Y,Z? I have a Regenerative Vacuum Pump that should handle the Platform table size. Have you looked into using a vacuum table?

-

08-08-2013, 02:50 AM #134

Banned

Banned

- Join Date

- Aug 2013

- Posts

- 8

Essentially cutting out the two 'X'S on the black piece under the table in this picture..

-

10-20-2013, 12:51 AM #135

Neuer Benutzer

Neuer Benutzer

- Join Date

- Mar 2006

- Posts

- 20

Beautiful design

Your background in architectural design really shines through with this machine.

-

11-23-2013, 06:13 PM #136

Registered

Registered

- Join Date

- Jul 2007

- Posts

- 166

Wow nice job!

-

12-08-2013, 11:15 PM #137

Member

Member

- Join Date

- Feb 2009

- Posts

- 72

What's the clearance from the bottom of the Gantry to the working surface if say you put in a T-slot insert? I looked around and basically looking for what the Z travel spec is or range. Currently using a Bosch Colt 1hp var speed on my present cnc and I usually could always use another 1" of travel. Looking to upgrade from my current HPDE CNC and this looks like a good candidate with a lot of the components I would use if I designed and built myself.

** Finally spotted it... 5.5" Z **

-

03-03-2014, 02:13 AM #138

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 203

Couple Updates!

It is time to make a long overdue update to this thread and collect a couple things I posted elsewhere into this one 'project' thread. It is hard to believe that a little over a year ago, I decided to offer to produce 5 kits for people if there was enough interest! I have now made 60 copies of this machine kit, 12 at a time as that is all that I can fit in my studio. I am currently in the middle of producing 12 more of these for delivery at the end of March, with another 12 on the horizon!

I would have never guessed the positive response that I have gotten for this machine, which was originally just meant for my own personal use!

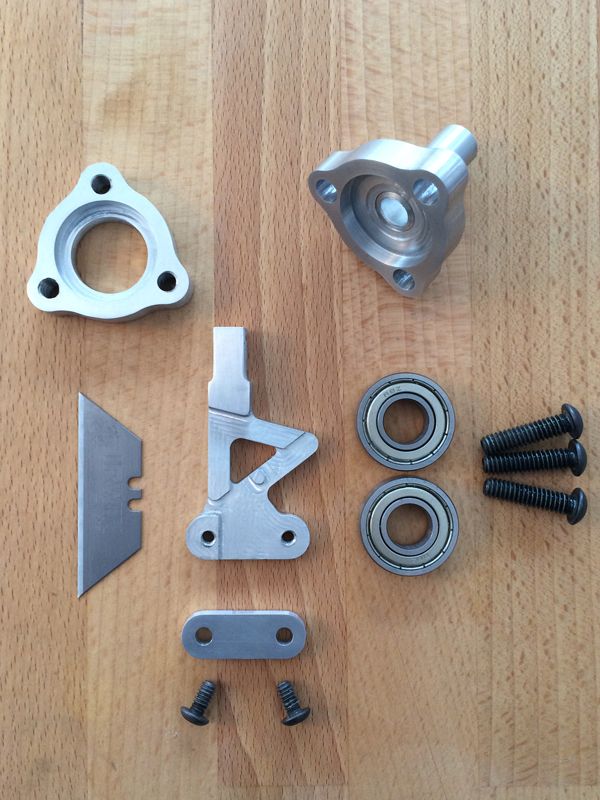

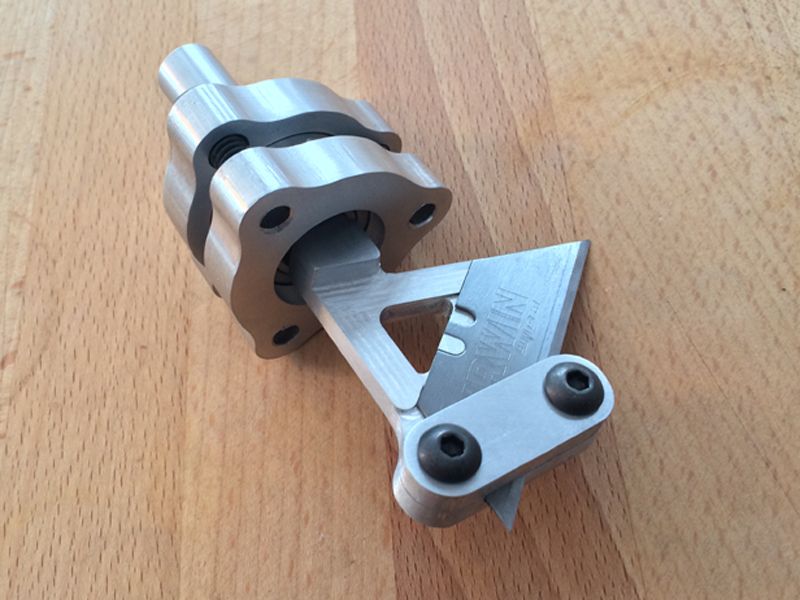

This hasn't left me a huge amount of my own tinker-time, but in case you missed it, I was able to make a drag knife as a compliment to the machine over the Christmas break!

Here are all of the parts for the drag knife...

The final knife assembled...

Here is the video of the process from initial mockups to project completion!

Video Link

I had hope to be able to figure out the plasma function by now, but luckily, one of the owners is extremely close and I look forward to seeing his progress over the next couple weeks in his build thread!

I am also currently busy making assembly videos as well for the Platform CNC! I just finished building my 2nd personal machine as I wanted to have the production version of the machine in order to be able to accurately R&D things based on the final production version. This was an excellent opportunity to document the entire process!

Here is a link to the first assembly video in the series!

Video Link

Also in case you missed it, here is a project I did on the Platform looking at how to fixture and mill a two sided project the lazy way!!!

Video Link

That's it for now! I hope to have more updates soon!

Brian

-

03-03-2014, 03:28 AM #139

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

That's a lot of machines!!

If you're going to have one at Maker Faire this year, I'm going to try to get out there and check it out.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

03-14-2014, 03:08 AM #140

Registered

Registered

- Join Date

- Jun 2012

- Posts

- 817

I could use one of those drag knives!

Similar Threads

-

Grunblau Platform CNC Groupbuy...

By Grunblau in forum DIY CNC Router Table MachinesReplies: 11Last Post: 10-14-2016, 03:39 PM -

Latest news on the Grunblau Platform CNC

By Grunblau in forum DIY CNC Router Table MachinesReplies: 29Last Post: 01-24-2015, 08:55 PM -

Grunblau MDF CNC My 1st Build!!

By Jkountz in forum CNC Wood Router Project LogReplies: 44Last Post: 09-26-2013, 09:20 AM -

Table build from Grunblau design

By fishin_fl in forum DIY CNC Router Table MachinesReplies: 8Last Post: 08-22-2013, 10:23 PM -

build a five foot sliding platform to hold 500-700 bls on end?

By lorec in forum 80/20 TSLOTS / Other Aluminum Framing SystemsReplies: 1Last Post: 08-25-2011, 01:47 AM

Reply With Quote

Reply With Quote