I am currently looking to buy a digital dial indicator, i was looking at getting this one, please let me know if its good or bad... Also if there are alternatives, not looking to spend more then $300. I would like a resolution of 0.001mm.

MITUTOYO ID-C112EB ABSOLUTE DIGIMATIC INDICATOR | eBay

Thread: Dial Indicator

Results 1 to 20 of 27

-

06-05-2012, 05:46 AM #1

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 278

Dial Indicator

Hive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

-

06-05-2012, 06:15 AM #2

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 419

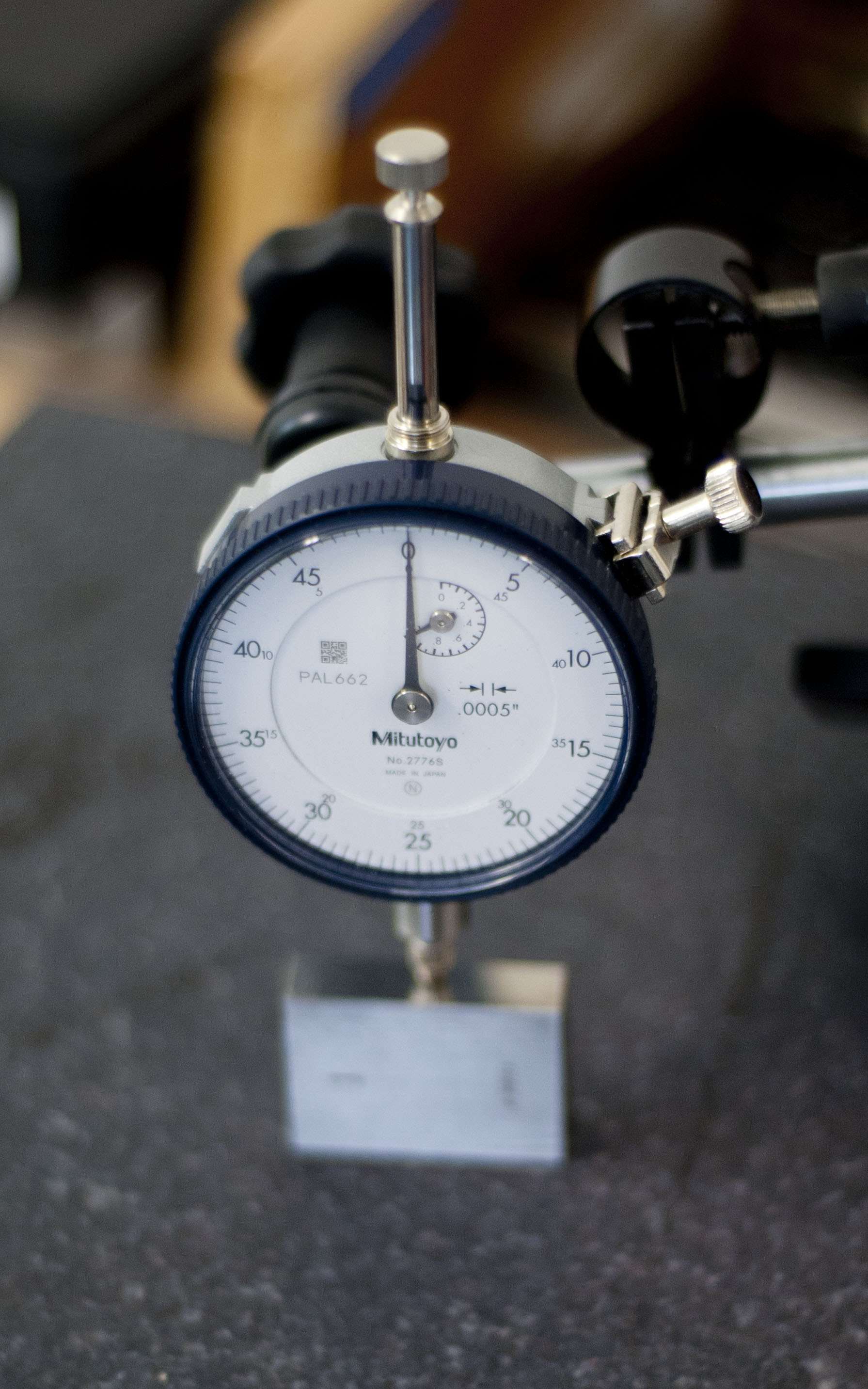

I'd personally recommend this guy:

055 : Mitutoyo 1" travel dial indicator

You get a calibration certificate showing error at all possible measurements. It is 0.0005" but you can read between the markings to tenths (assuming you have a setup rigid enough to make tenths meaningful). I am not convinced that a 0.0001" indicator is worth 3-5 times more money, especially if they have less than 1" travel.

It is the only of my four dial indicators that measures 1" bang on, all my import indicators are off by a thou or more:

Just a personal preference, but I much prefer using a test indicator for measuring in tenths. It is nice to have both types of indicator since they are used for different tasks.

Mitutoyo "Quick-Set" Test Indicator Sets With Dovetail Mount << Precision Measuring << Online Catalog << Penn Tool Co.

You can get the pair for under 300$ and they will be new. Enco has both.

-

06-05-2012, 06:24 AM #3

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 278

Thank you for the info, i actually got a 12 x 18 inch granite surface Grade AA i think they shipped me the wrong one since i ordered Grade A, the test report says its all within 0.001mm.

I would like to use if for scrapping, that's why the resolution of 0.001mmHive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

-

06-05-2012, 06:53 AM #4

Registered

Registered

- Join Date

- May 2012

- Posts

- 0

If your looking for absolute most accurate my vote would be interapid...No doubt the best indicators on the market..Want something almost just as good if not just as good,my money goes to browne and sharpe...I would never waste my money on a mitutoyo though!!no offence to the poster below but they dont last for ****!! There indacators are the best tool they make from my exeprience, but I think thats because they get used alot less than your average mitutoyo tool like there calipers. So there indicators dont wear as fast as typical mitutoyo tools.

-

06-05-2012, 01:42 PM #5

Gold Member

Gold Member

- Join Date

- Feb 2006

- Posts

- 7063

"I would like a resolution of 0.001mm" - Good luck with that! That's less than half a ten-thousandth! You may find something that will let you discern a difference to near that level, but accurate to that level? Forget it. And NOTHING else on the machine will be within even an order of magnitude of that accuracy.

Regards,

Ray L.

-

06-05-2012, 02:14 PM #6

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

In the subject line you say "dial indicator" and in your initial post you say "digital dial indicator". I have never liked the digital indicators. A dial indicator has always seemed much more useful especially when really using it to indicate something, like a part you are tring to dial in on a four jaw lathe chuck. Also, 0.001 mm?? As in 0.000039"? What in the world would you need an indicator with that kind of precision for? Even if it has graduations that low, the guaranteed accuracy is probably 0.0001" at best. I personally like Brown & Sharpe, and Starrett indicators, but have some cheap import ones too. Most of the time, you aren't going to be using the indicator's full range, so if it is off a thou or two over 1" it won't matter too much. For example, tramming in a mill head. Say your tramming tool has 2 cheapo 1" dial indicators but when tramming, the needle is only moving a few thou, so if the indicator is off 0.002" over 1", then that interpolates to 0.000004" over 0.002", so it won't matter in that case. It all depends on what you are using it for.

-

06-05-2012, 08:42 PM #7

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 278

This particular dial indicator will be used for scraping, not on a machine, i need it to have that resolution, resolution and accuracy are two different things. I know i will be needing a temperature controlled room, which i have (steady at 20C). If i want to scrap within 0.005mm then i need my equipment to be better then that.

A digital indicator not necessarily i guess, just thought with technology things are moving into the digital age and linear scales maybe moved into indicators...

For tramming i already have something else which works great.

Also i wont be needing full 1" movement for the indicator since i max need maybe 12 to 15mm.

I don't have the money for a CMM yet, that's something i am planning for the future. If anyone knows where i can pickup one for cheap let me know

I will have a look at Starrett and Brown & Shape.

Edit: i have my eye on this one now... http://www.grainger.com/Grainger/BRO...CL2?Pid=search or this http://www.grainger.com/Grainger/MIT...RC3?Pid=searchHive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

-

06-05-2012, 11:51 PM #8

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Need to determine if you are going to use a test indicator and/or dial indicator and the amount of use/environment that the indicator will be used. The range/linerity is dramatically different between the two types of indicators. I use Interapid and Compac test indicators, Starrett dial indicators and have been very happy with the performance of these brands. At the prices you are looking at you might consider one of the following.

Starett 25-511J or 611J Dial Indicator, 2 1/4", 0.0001" gradations with 0.200" travel

Starrett Dial Indicators, Series 25 Dial Indicators

STARRETT DIAL INDICATOR 25-611J ~ New in box | eBay

Metric series: 25-151, 2 1/4", 0.001mm and 0.25mm travel

Starrett Dial Indicators, 25 Series Dial Indicators with Millimeter Graduation

Test Indicator, something like the Interapid 312B-3

Interapid Swiss Test Indicators << Precision Measuring << Online Catalog << Penn Tool Co.

-

06-06-2012, 12:26 AM #9

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 278

Thank you so much for the info on these products. I like the metric once better since i am from Switzerland.

What are you guys thinking about digital once compare to the mechanical items... I would rather go digital.Hive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

-

06-06-2012, 05:09 PM #10

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 0

Do not particularly care for digital in this application if I am measuring a surface, may be more applicable to doing measurement/QC in a static repeatable situation, but digital can provide higher resolution and has digital output if required. It is hard to comment on what would work best without knowing the full details of what and how you want to accomplish your measurements/accuracy. Since you prefer metric I did note that the Inerapid (TESA) is available in a metric model 312-3, but as others have noted the gradations and accuracy you desire may not be possible with an analogue indicator, inclusive of other errors within your measuring apparatus. You might call Long Island Indicator Service and ask their recommendations or another service that has expertise to guide you.

[ame="http://www.amazon.com/Brown-Sharpe-TESA-Horizontal-Graduation/dp/B0006J4WBS"]Brown & Sharpe TESA 74.111368 Interapid 312 Dial Test Indicator, Horizontal Type, M1.7x4 Thread, 2mm Stem Dia., White Dial, 0-10-0 Reading, 37.5mm Dial Dia., 0-0.4mm Range, 0.002mm Graduation, +/-0.004mm Accuracy: Amazon.com: Industrial & Scientific[/ame]

-

06-06-2012, 06:48 PM #11

Registered

Registered

- Join Date

- May 2007

- Posts

- 767

Both have their own distinguishing advantages and disadvantages. Digital readout is dependent on the instruments sampling speed and the slight variations due to lack of rigidity can / does make it difficult to interpret as the least significant digits thrash about. This is where the ability to set tolerances helps. The mechanical type just displays a waving needle which is easy to interpret but can give an impression of a greater variation than actually being experienced. Some digital instruments have an analogue scale which gives a sluggish response but again it is a case of horses for courses. I use a digital instrument when using a rigid stand on a surface plate or as a go nogo gauging on a work piece that is still on a machine. For all other cases I prefer a mechanical device. The electronic instruments suffer if used in a workshop that varies in temperature more than their mechanical cousins and they have a habit of requiring a battery change at the most inconvenient times or go into an auto switch off mode requiring buttons to be pressed possibly disturbing the set up.

IMHO instruments of similar cost have similar life and general reliability. My money is on Mitutoyo as they have instruments for a wide range of applications and including some low cost ones in addition to very sophisticated measurement systems.

PS. many digital DTI can read out in metric or inch at the press of a button. I would look for tolerance settings for any new purchase as this so convenient and once experienced makes instruments that do not have it a chore to use.

Good luck with your eventual purchase. Regards - Pat

-

06-06-2012, 07:09 PM #12

Registered

Registered

- Join Date

- Apr 2005

- Posts

- 419

Consider that scraping requires mostly relative measurements. In almost all cases you are checking parallelism/perpendicularity of a surface by comparing readings at two points.

You don't require absolute accuracy nearly as much as repeatability. You can a 0.0001/0.00005" test indicator fairly cheaply when compared to the other options. If you watch some scraping operations you will see that a test indicator can be used for all the required measurements, but a regular indicator cannot.

Scraping in a lathe's top slide (with tapered gib) - YouTube

-

06-09-2012, 06:03 AM #13

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

A bit off topic, but I got curious about just how bad my cheapo import dial indicators are so I checked them. I bought 3 of these indicators on sale at Harbor freight for $10 each a while back. They are 1" travel indicators and I tested them all. This is the worst one of the bunch. I used a 1" micrometer standard and the temp in my shop was 73 degrees F. Less than 0.0005". Not to darn bad for a $10 indicator if you ask me.

-

06-09-2012, 07:36 PM #14

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 278

Did You try different heights 5, 10, 15, 20, 25 mm... to see if it is linear.

Hive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

-

06-09-2012, 10:20 PM #15

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

I don't have a set of gauge blocks or a granite block. Those are on my list of things to get. Since I don't have them yet, I could only use my mill table and the 1" micrometer standard. So, to answer your question, no I didn't because I didn't have the equipment to do it. As I was typing I happened to think that I suppose I could mic the diameter of a couple end mills and use them to see. I could do 3/8" 1/2", 5/8" and 3/4" since I have end mills those diameters. I'm going out in the shop in a few minutes and will do that. I'll report back.

-

06-10-2012, 03:14 AM #16

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

I checked all three of my Harbor Freight indicators using 3/8", 1/2", 5/8" and 3/4" end mills. Each end mill measured within 0.0001" of nominal using my 1" micrometer. On all measurements they were all right on with no perceptible error. The only error I get is with the one indicator at 1" extension.

-

06-10-2012, 08:29 AM #17

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 278

That's pretty good...

. What are you using them for, mostly tramming and things like that.

Hive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

. What are you using them for, mostly tramming and things like that.

Hive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

-

06-10-2012, 09:18 AM #18

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1943

My plans for them are 2 will be used in a tramming aid for mills if I ever get around to making it, one I am using on my non-cnc lathe for accurate positioning like when turning up against shoulders. I already had another 1" travel indicator for general indicating tasks, a 0.2" back plunger indicator, and a test indicator. The price was too good to pass up.

-

06-10-2012, 09:50 AM #19

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 278

Yes for $10 each that's a good price...

Hive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

-

06-14-2012, 12:50 PM #20

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 278

Ok got what i needed / wanted /dreamed off

maybe a little overkill...

maybe a little overkill...

Electronic Digital Indicator, +/-0.040 In - Electronic Digital Indicators - Measuring and Layout Tools - 5RHJ4 : Grainger Industrial SupplyHive 8 - G0704 CNC Mill - 20 inch Telescope - High Resolution 3D Printer - Lasersaur 100W CO2 Cutter / Engraver

Similar Threads

-

Dial indicator -advice?

By Kalvin in forum Benchtop MachinesReplies: 23Last Post: 04-04-2013, 01:09 PM -

I can use a drum dial as a dial indicator can't I?

By slashmaster in forum Benchtop MachinesReplies: 2Last Post: 11-03-2010, 06:10 AM -

Dial indicator question

By cwm9 in forum Metalworking- / Woodworking Tooling / Manual MachiningReplies: 20Last Post: 12-17-2008, 09:15 PM -

Dial indicator

By hkrok in forum News AnnouncementsReplies: 1Last Post: 08-17-2007, 01:49 AM -

what does dial indicator use to measure?

By cnc2k in forum MetalWork DiscussionReplies: 9Last Post: 07-16-2005, 01:20 PM

Reply With Quote

Reply With Quote