This new Drag knife does not require any special software or Hardware to cut most shapes.

It orients itself the same way the wheel (caster) on your office chair orients itself.

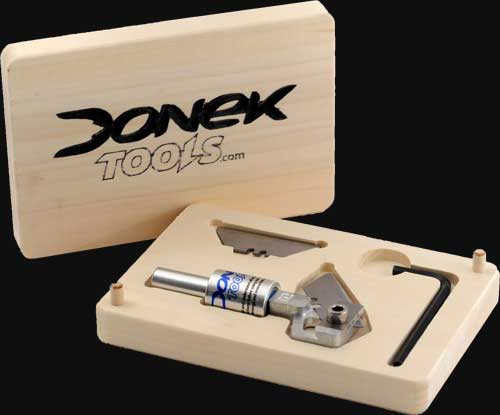

The tool Clamps into any 1/2in Collet on a Router or Spindle and cuts materials as thick as 1/4in.

Donek Drag Knives are designed to use standard utility knife blades.

The Donek Drag Knives can be used to cut exact curves and sharp corners in wood veneer,

plastics, cardboard, gasket materials, leather, and more. If you can cut it with a utility knife,

you can probably cut it faster and more precisely with a Donek Tools Drag Knife.

We offer free software utilities that make your Donek drag knife even more versatile.

Cut Cardboard boxes to the dimensions you require simply by entering the finished dimensions.

We have a free utility that adds corner actions to your tool paths, allowing you to cut sharp corners.

For more details and videos of the Donek Drag Knives in action visit our web site.

www.donektools.com

Thread: Low Cost Drag Knife for any CNC

Results 1 to 5 of 5

-

09-16-2012, 03:42 PM #1

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 13

Low Cost Drag Knife for any CNC

-

09-18-2012, 06:10 AM #2

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 13

-

09-21-2012, 06:28 AM #3

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 13

People keep finding new things they can do with our drag knife. A local composites shop just started using it to cut prepreg carbon fiber laminates. Until now, they've hand cut these laminates and some waste is generated as a result of inaccurate cutting. Our drag knife is faster and more accurate.

-

04-15-2015, 05:11 PM #4

Registered

Registered

- Join Date

- Apr 2015

- Posts

- 7

I have a problem using Drag Knife

Drag Knife

I have a problem using my CNC with the Aspire Program.

I have been watching all the tutorials and reading all the comments but my drag knife doesn't turn with the lines and get broken. I follow all the steps and the problem still be there.

How can I control the elevation of the drag knife in Z ,for change the lines, because in the Aspire program I couldn't find the Z's set up?

I will appriciated the help, and if somebody knows how fix it, please send me screen shoots, pictures or videos for how you set up the elevation of the drag knife in Z.

Thank you very much!

Maximiliano

-

04-15-2015, 08:35 PM #5

Registered

Registered

- Join Date

- Jul 2012

- Posts

- 13

Re: I have a problem using Drag Knife

The best practice is as follows:

surface or fly cut your table to ensure it is totally flat and true to your machine (most important step)

zero your cutter to the table surface, not the top of your material.

make test cuts in your material, lower or raise your blade until the knife is just barely cutting through the material

set this position as your z-zero

Vectric Gadget settings:

be sure you set the z zero to the bottom surface of your material and be sure to enter an accurate value for thickness

never rely on the manufacturers stated value, measure the material with a caliper or micrometer.

In the drag knife gadget:

set cut depth to the material thickness (the same you enter previously)

swivel depth should be between 0.001in and 0.010in depending on the flatness of your material and how consistent it's thickness is.

passes should generally be 1 unless you are cutting particularly hard materials

blade offset varies from machine to machine and is dependent on the model you use (see below)

tolerance angle should be left a 20deg

select a tool with a feed rate in the range of 3 to 5in/sec (180 to 300 in/min, or about 6000mm/min)

Additional advice on cut order and start points

select your paths in the order you want them cut.

it is always wise to cut internal components before external components

adjust the start points of your vectors to be in the middle of a line or large curve

the vectric gadget likes to start cuts at corners, but fails to reorient the blade at the end of the part resulting in an incomplete corner

adjust the start points on all vectors such that they begin and end in the same orientation

this reduces the need to reorient the blade at the beginning of a cut and makes your tool paths begin and end on top of each other.

keep in mind that the vectric gadget will cut all closed paths in a counter clockwise direction

Advise on determining blade offset for your tool and machine.

The best starting point for a D1 or D3 tool is 0.065in

The best starting point for a D2 or D4 tool is 0.160in

depending on backlash and other factors in your machine, these values may not be accurate enough

The best way to fine tune this value is to cut test pieces. I recommend a 1.5in square.

observe the tool in action

if the tool turns too much at a corner, then the offset value is too large

if the tool does not turn far enough at a corner, then the offset value is too small

typically adjustments of 0.005in are recommended.

repeat your test cut.

Similar Threads

-

using a drag knife

By woodman08 in forum Gorilla CNC MachinesReplies: 5Last Post: 05-10-2021, 12:03 PM -

Drag Knife toolpaths

By mcphill in forum BobCad-CamReplies: 12Last Post: 08-13-2017, 11:46 PM -

Drag Knife Tutorial

By donek in forum VideosReplies: 4Last Post: 04-15-2015, 08:37 PM -

drag knife

By cocojack1966 in forum Other Machine TopicsReplies: 6Last Post: 05-12-2014, 06:11 PM -

more drag knife cuts

By woodman08 in forum Gorilla CNC MachinesReplies: 0Last Post: 02-10-2013, 03:17 AM

Reply With Quote

Reply With Quote