Yo ,

I needed a mill ... liked the PCNC 1100 from tormach , but is expensive ...

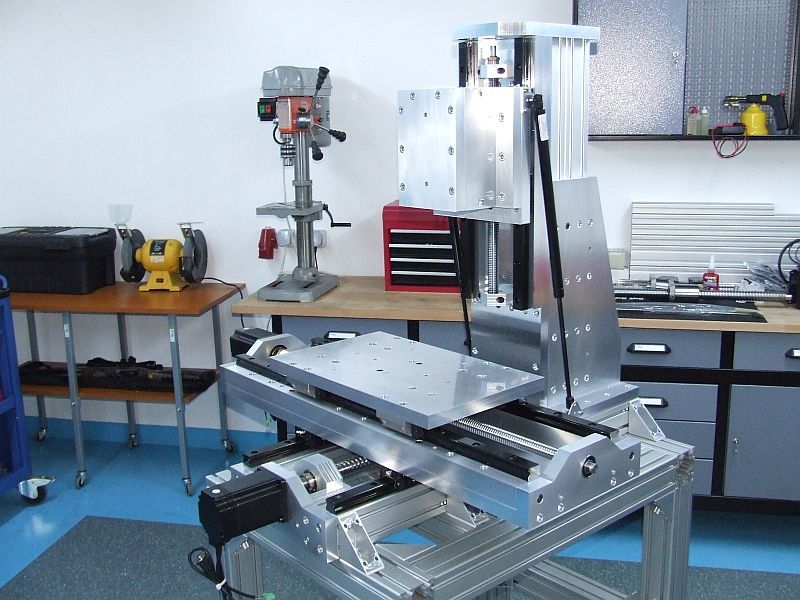

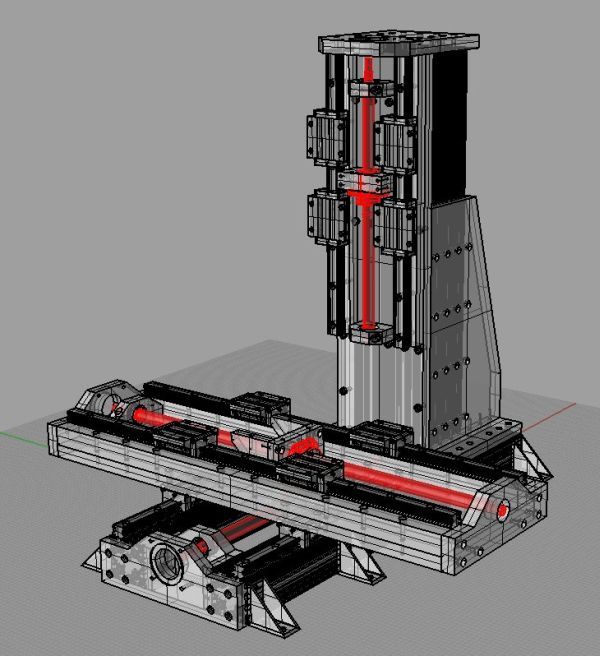

so I decided to build my own , from scratch ... Design is very common

( so far I have seen several machines here almost identical ... ) .

My english is not so good , so I will let pics talk for me ...

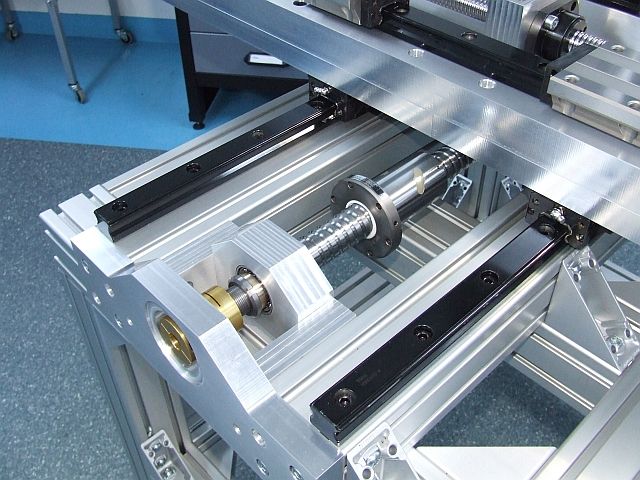

All aluminum components were machined on my cnc router ( my last

project , finished 3 months ago ) . First picture is taken in my shop ,

reprezenting my cnc router .

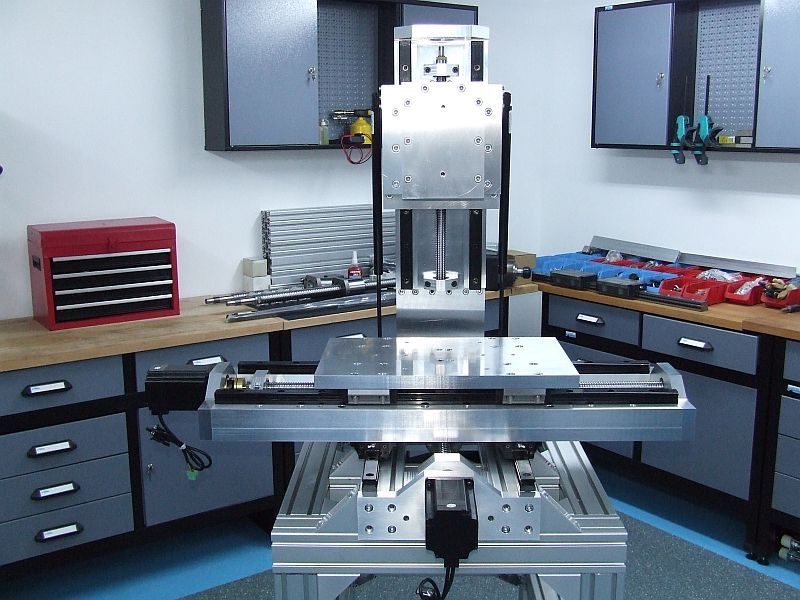

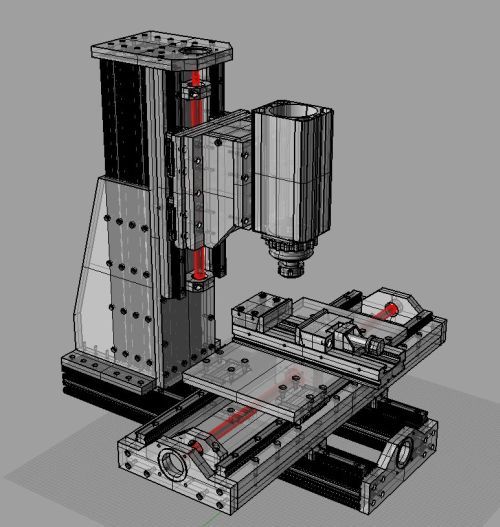

Here it is ...

I stiil have a lot of work ahead , but I think I will finish this year .

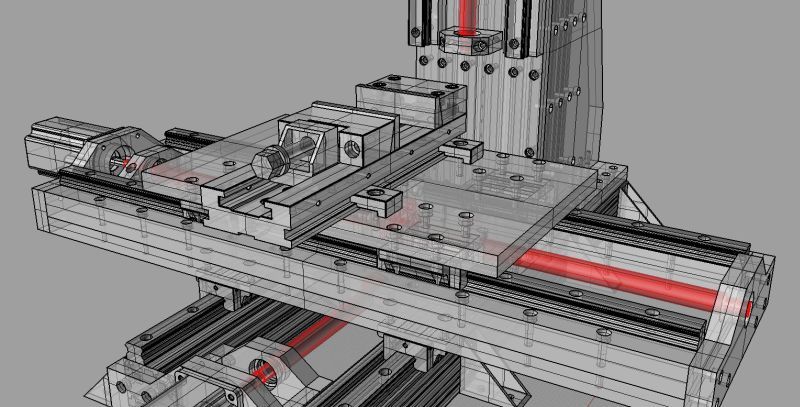

Components :

THK SHS30CA rails , 80_80 aluminum extrusions , 1" thick MIC-6 aluminum

plates , ISEL 2505 ballscrews on Y and Z , LeadScrewInternational precision

ground 3210 ballscrew on X , Colombo RV110.22 / 10hp + Delta drive ,

As for motors , I will use those weird hybrids from keling ... closed loop

stepper motor kits ( 8N/m stepper motor , 1000ppr encoder , digital hybrid

servo drive ) .

I'll be back !!!

Results 1 to 20 of 123

-

10-22-2012, 08:21 AM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

cnc vertical mill build log ( pics )

-

10-22-2012, 12:21 PM #2

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

again WOW!

-

10-23-2012, 12:00 AM #3

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 266

damn that's gorgeous!

my first..."Big Ape" CNCRP 2448 Build Log

-

10-23-2012, 02:14 AM #4

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

Thank you .

I assume that you are reffering to the vertical mill ... it's a work in

progress , it will look much better at the end .

If you are talking about the router , that's nothing ... I have an idea

that's much better then this . AC servo , BT30 spindle with ATC , work

table made from a single piece of aluminum ( 2" thick MIC-6 plate ) ,

vacuum clamping sistem , 8 by 4 working area , Newall DRO ( just for

fun ) , an so on ...

-

10-24-2012, 02:40 AM #5

Registered

Registered

- Join Date

- Apr 2009

- Posts

- 266

complete cnc nublet here so forgive my ignorant questions...

you are making a gorgeous cnc mill mostly out of aluminum, right?

how rigid and strong is this... or how does this compare to a equivalent sized machine made of cast metals and steel in terms of performance?

thanks in advance,

Almy first..."Big Ape" CNCRP 2448 Build Log

-

10-24-2012, 03:36 AM #6

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 371

Holy smokes, your workshop is far too clean. I'm so jealous!

-

10-24-2012, 09:05 AM #7

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

I have no idea ... but I also have no posibility to work with cast metal or

steel . so , I used the next best thing. But I really hope that the machine

will perform well . It's already heavy ( 250KG / around 500pounds ) , the

design is fairly good , and it's stiff ... entire assy is only at mokup level

now ( very few screws , about 10% of final amount needed ) , nothing

is aligned yet , and still , the entire **** does not vibrate when I strike

the column with a rubber hammer ...

Here are some pics of final project , made in Rhino ... You will see that

the base structure is pretty solid ...

-

10-24-2012, 09:24 AM #8

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

10-24-2012, 11:46 AM #9

Registered

Registered

- Join Date

- Dec 2011

- Posts

- 0

colour me green!

Megesh Govender - South Africa

Newbie to CNC

-

10-24-2012, 12:35 PM #10

Registered

Registered

- Join Date

- Oct 2011

- Posts

- 218

Amazing clean workshop do you have cleaners come in? :-)

Sent from my iPhone using Tapatalk

-

10-24-2012, 01:30 PM #11

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

Beautiful work. Thnks for sharing, and I am looking forward to seeing the further build pictures.

Regards,

Mark

-

10-25-2012, 01:02 AM #12

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 169

:wee::banana:WOW

-

10-25-2012, 11:25 PM #13

Registered

Registered

- Join Date

- May 2005

- Posts

- 35

Can't wait to see a video of that mill working.

Keith.

-

10-26-2012, 12:17 AM #14

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 180

-

10-26-2012, 06:58 AM #15

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

10-26-2012, 05:10 PM #16

Registered

Registered

- Join Date

- May 2005

- Posts

- 35

Looks like a great finish on your profile cuts what do you use to cut the profile with ?

Keith.

-

10-26-2012, 05:53 PM #17

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

Profiling toolpath is generated with Artcam , based on vector ( DXF file ) .

I use a carbide cutter ( 10mm dia , 3 flutes , 45 degree helix ) at 8000rpm .

And a lot of WD-40 ... the machine is set-up true and square , maximum

error around 0.02mm .

Cutting speed is around 800mm/min , depth of cut 2mm . The blank is cut

on a bandsaw ( Craftsman Pofesional , imported too from USA ) , slightly

bigger than the finished part ( about 2-3mm ) . So the cutter does not

have much job to do ...

-

10-27-2012, 06:26 PM #18

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

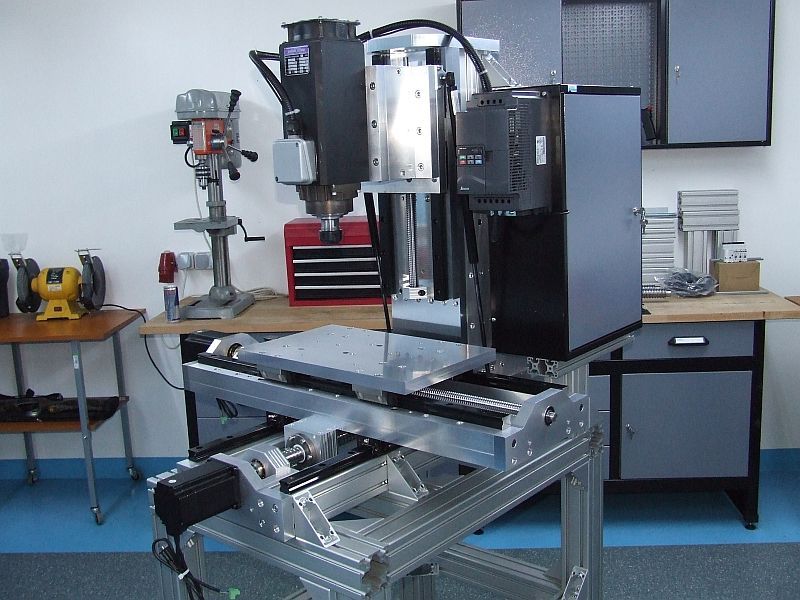

Update :

It's starting to look like a mill ... The head , the compensation struts ,

motors on X and Y . Verified the weight compensation ( with the motor

mounted , I can actualy move the Z axis with 2 fingers ... very easy ) .

Without the motor , it wants to go up ...

Now I have to wait for the third motor ( on Z axis ) , still on transit from

keling , and the power supply ( can't wait to test movements ) .

pics:

....................................

-

11-03-2012, 05:57 PM #19

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

Update :

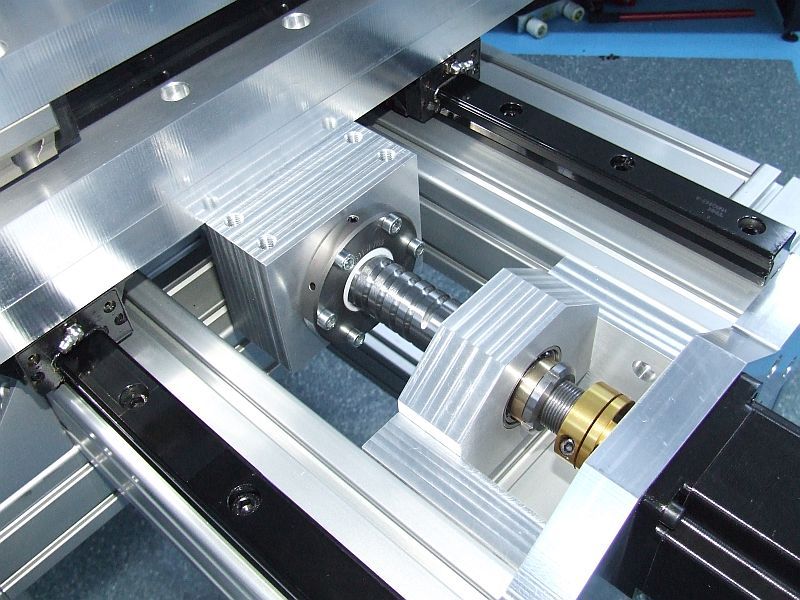

The ballnut block on base axis . Milling motor is now in place , also

found a box for electronics ...

........................

-

11-04-2012, 04:07 AM #20

Gold Member

Gold Member

- Join Date

- Aug 2004

- Posts

- 2849

Katran,

Beautiful work and a beautiful workshop.

What extrusions are you using for the z-axis. It looks like you are using 4 extrusions of the smooth variety, but unsure of the size.

What are you using to hold the extrusions together....besides the front Mic6, the side and the top plate?

Thanks for the great pictures.

Paul

Similar Threads

-

DIY aluminum vertical mill build

By sergizmo in forum Vertical Mill, Lathe Project LogReplies: 81Last Post: 09-07-2015, 04:59 PM -

400W Mitsubishi HC-PQ43 Servos - choice for Vertical mill build

By fcp in forum Servo Motors / DrivesReplies: 0Last Post: 01-05-2013, 11:51 PM -

Looking to build a simple vertical mill

By Crudeau in forum Benchtop MachinesReplies: 7Last Post: 10-27-2012, 01:13 PM -

Custom CNC vertical Mill build T-Minus 24:00

By cncgabe in forum Vertical Mill, Lathe Project LogReplies: 37Last Post: 03-31-2012, 02:18 AM -

Started build on CNC Mill. Lots of pics, sorry.

By EvanZ in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 02-17-2008, 02:24 PM

Reply With Quote

Reply With Quote