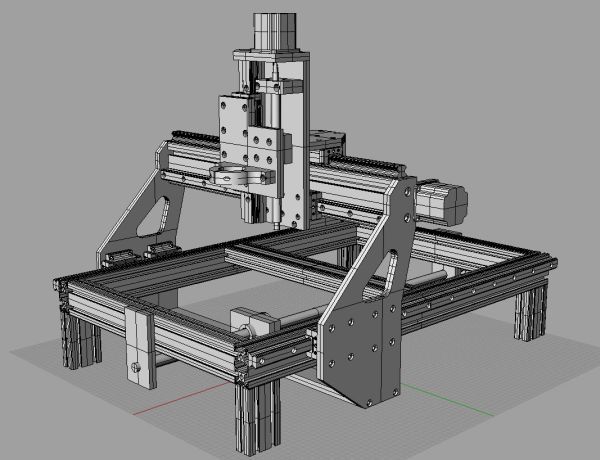

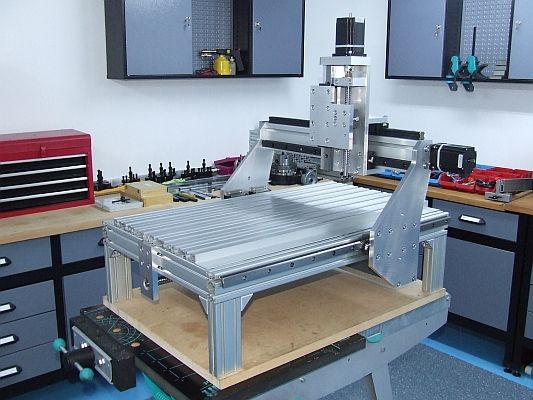

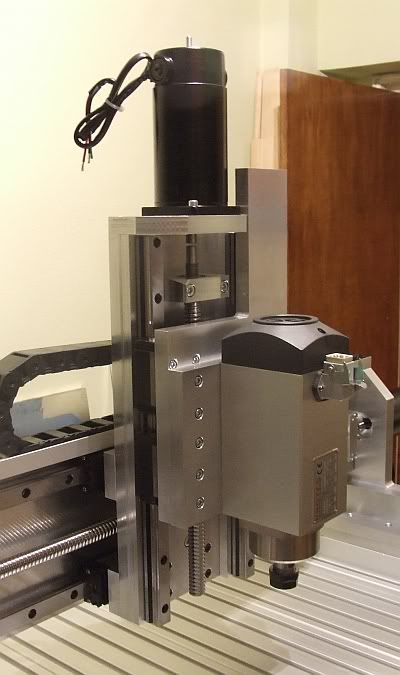

My cnc router , finished about 3 months ago .

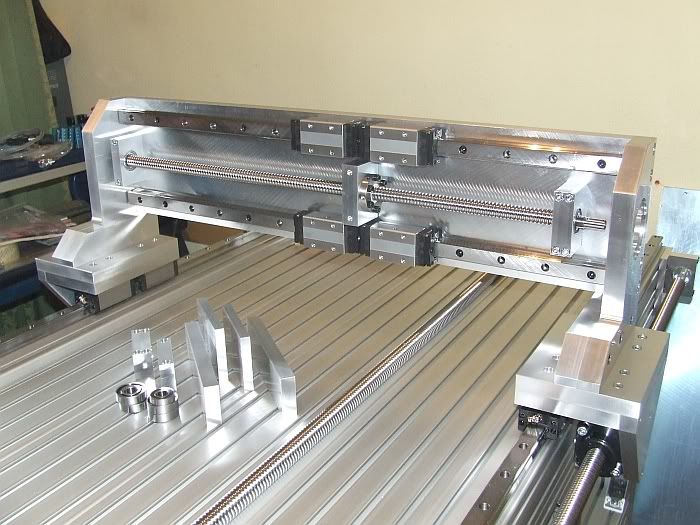

Components :

80_80 aluminum extrusions ,THK SHS25R rails on all axes , ISEL 2505

ballscrews , 1" MIC-6 aluminum plates , 2.2Kw Protec motor ( max 24000rpm

ER20 nose ) plus Delta VFD/drive , servo motors ( keling , aprox. 500W ,

with CUI AMT encoders ) .

Rapids at 8m/min , cuts aluminum easy , nice finish ( with some help

from WD-40 ) . Maximum depth of cut using a 12mm carbide endmill : 3mm

at 800mm/min feed , 8-10000rpm ( tested , but I think it can do better ) .

Working anvelope : 950mm x 650mm x 150mm .

.................................................. ...............................................

Thread: cnc router build ( pics )

Results 1 to 20 of 24

-

10-22-2012, 10:38 AM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

cnc router build ( pics )

-

10-22-2012, 10:41 AM #2

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

that is an awesome looking machine

must be a shame to get it dirty by actually using it!

-

10-22-2012, 11:05 AM #3

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

Man , you have no idea how much time I spend cleaning the machine after each and

every job ... But it has to work like a horse , I spent around 6000usd building it .

The components were not so expensive , but keep in mind that I have to actualy

import every bit of it from ebay sellers ( mostly U.S ) to Romania ...

It looks O.K , it works fine ( about 0.025mm error at 1000mm ) . I can do better , but

my free time is very little ... I work in shifts ( air traffic controller ) , I have a family to

take care of ...my little girl just begun school ... my life is , lets say , complicated ...

-

10-22-2012, 11:36 AM #4

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

A short movie , testing machine at 6000mm/min . Low quality , sorry ...

-

10-22-2012, 11:39 AM #5

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

-

10-22-2012, 11:41 AM #6

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

That is just spectacular! What a brilliant job you've done building it!

cheers,

IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

10-22-2012, 12:07 PM #7

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

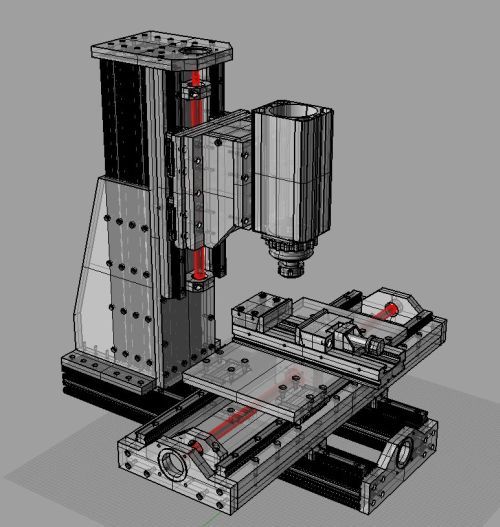

I made a little cnc router ( first job ever on this machine ) :

...now I am buiding a cnc vertical mill ...

actualy , there is a buld topic here :

http://www.cnczone.com/forums/vertic...build_log.html

P.S :

what the hell is " PPL " ?

-

10-22-2012, 12:09 PM #8

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

10-22-2012, 12:22 PM #9

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 0

just checked your other thread

stunning piece of kit there!

PPL = private pilot license

-

10-22-2012, 04:33 PM #10

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 521

Beautiful work. Does aluminum grow on trees in eastern europe?

-

10-22-2012, 05:28 PM #11

Registered

Registered

- Join Date

- Mar 2012

- Posts

- 276

Amazing work.

My CNC Router Build - http://tinyurl.com/c3vs3ca

-

10-22-2012, 07:46 PM #12

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

10-22-2012, 08:31 PM #13

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Excellent work! I like how you have the table fully supported in the mill, that should produce some nice stuff.

I've purchased from Shapiro Supply in the past and they are great people to deal with.

-

10-22-2012, 10:11 PM #14

Member

Member

- Join Date

- Apr 2007

- Posts

- 1955

Very nice routers and mill build work.

I was surprised at just how quiet that servo drive is.

-

10-22-2012, 11:00 PM #15

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

Indeed , servo motors are much quieter then stepper ... It is a pain

in the ass trying to tuneup the drivers corectly ( PID / Gecko 302x ) ,

but if you get it right , is very quiet , fast and precise .

-

10-22-2012, 11:05 PM #16

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 66

After seeing your builds..I feel like setting fire to mine and starting over. Excellent quality work.

http://www.youtube.com/user/rawdawgs50

-

10-23-2012, 02:27 AM #17

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 118

-

10-23-2012, 05:49 AM #18

Registered

Registered

- Join Date

- Nov 2010

- Posts

- 0

Another beautiful machine,

Thanks for sharing

-

10-23-2012, 07:07 AM #19

Member

Member

- Join Date

- Apr 2007

- Posts

- 1955

-

10-25-2012, 10:29 AM #20

Registered

Registered

- Join Date

- May 2005

- Posts

- 35

WOW!!!

Absolutely fantastic work really inspires me. My machines are really ulgy compaired to yours, time for me to start over all I need is time!!!!

We have probably spoken before as I often fly through your airspace enroute between the Middle East and Europe.

Keith.

Similar Threads

-

cnc vertical mill build log ( pics )

By katran in forum Vertical Mill, Lathe Project LogReplies: 122Last Post: 02-18-2024, 03:54 PM -

My SX2 CNC build! (lots of pics)

By asifjahmed in forum Benchtop MachinesReplies: 37Last Post: 04-15-2016, 06:31 AM -

illeboc-r's first cnc build in pics and diagrams

By neurofen in forum DIY CNC Router Table MachinesReplies: 255Last Post: 05-30-2012, 07:24 PM -

New CNC machine build (big pics)

By ckm in forum Vertical Mill, Lathe Project LogReplies: 15Last Post: 04-30-2012, 11:49 PM -

Can I Build A Cnc Table Out Of These Parts?? Pics

By douglasco in forum Open Source CNC Machine DesignsReplies: 12Last Post: 11-04-2008, 12:34 AM

Reply With Quote

Reply With Quote