Thread: Andrew's G07040 build

Results 141 to 160 of 241

-

07-21-2014, 08:04 PM #141

Member

Member

- Join Date

- Apr 2006

- Posts

- 8159

Re: Andrew's G07040 build

http://www.hossmachine.info - Gosh, you've... really got some nice toys here. - Roy Batty -- http://www.g0704.com - http://www.bf20.com - http://www.g0602.com

-

07-22-2014, 06:19 AM #142

Registered

Registered

- Join Date

- Sep 2006

- Posts

- 37

Re: Andrew's G07040 build

Hi Hos

thanks for that

Bob

-

07-24-2014, 02:30 PM #143

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

-

08-14-2014, 09:57 AM #144

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

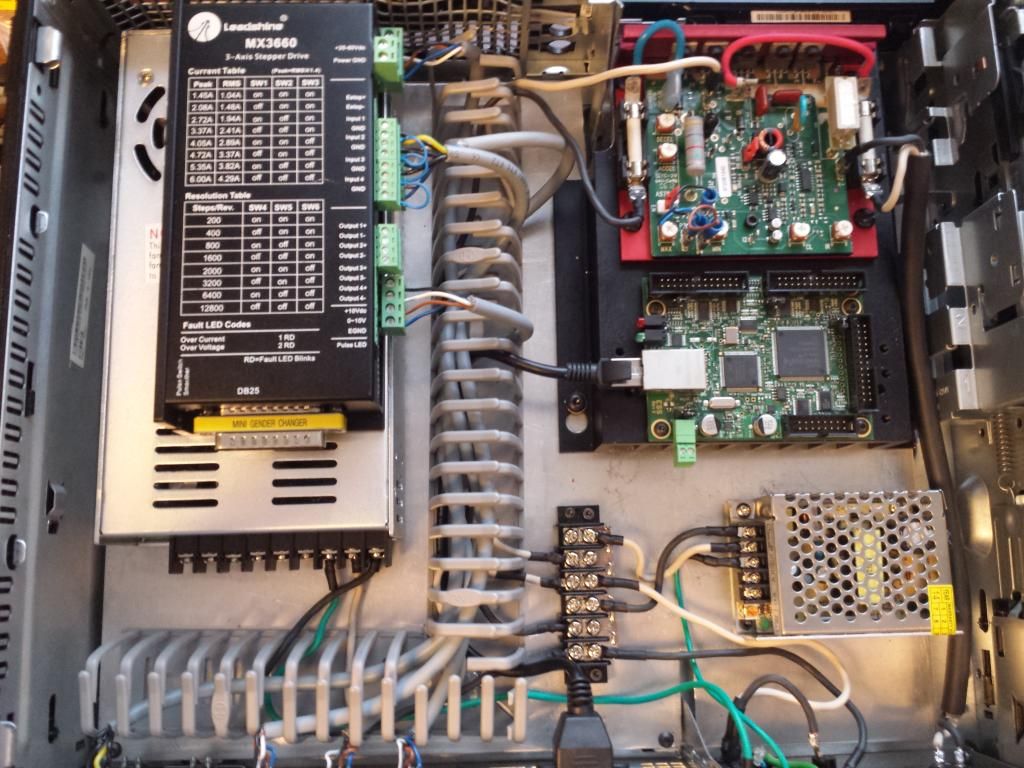

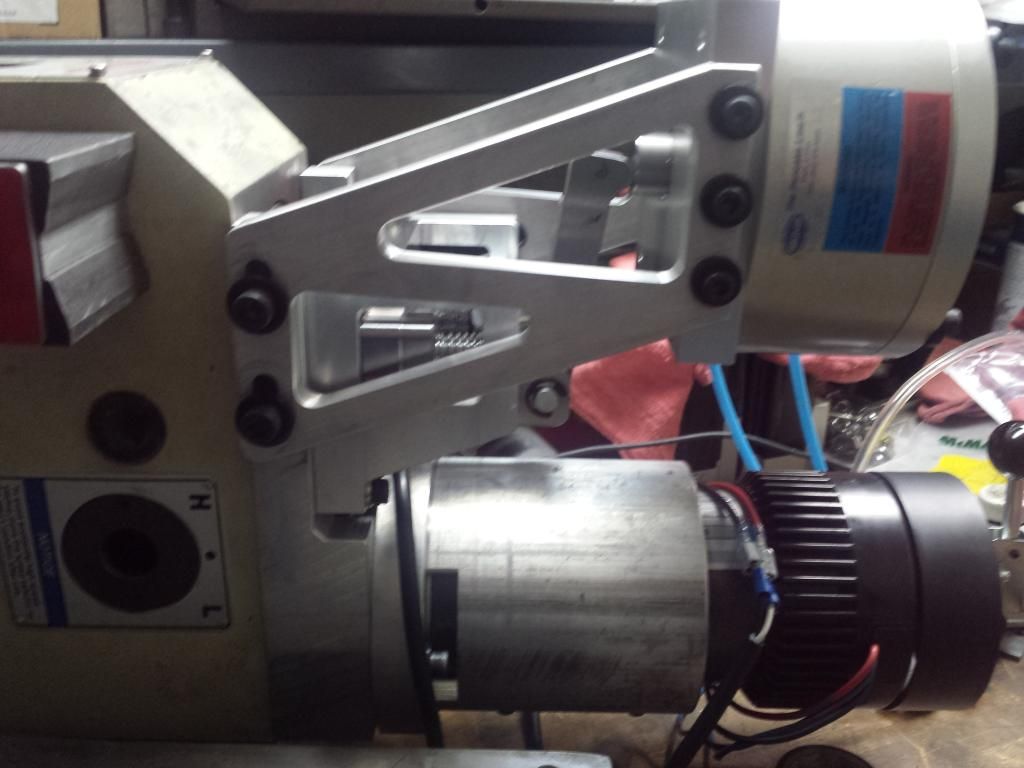

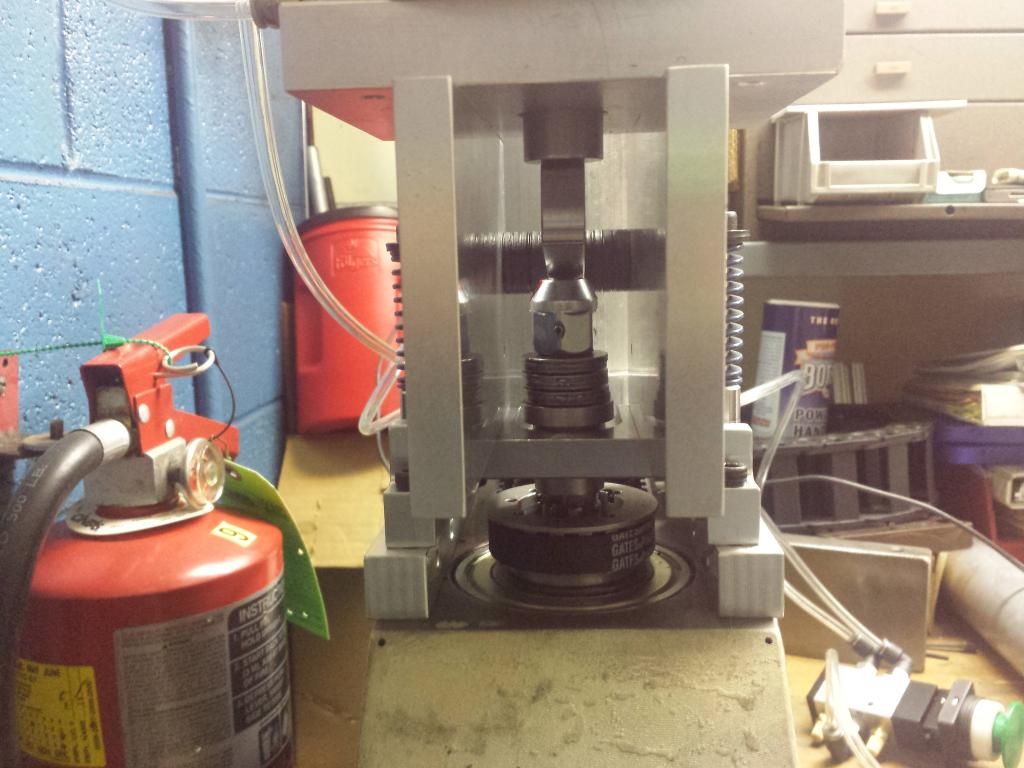

got the PDB done but then had to change the design to keep the pressure off the quill

redesign

Not the best but works and I'm going to run with it for a while.

Ordered some TTS style tool holders the China via Ebay. 6 x ER 20, 2 x ER 25 and 2 X ER32. They will have the grove for ans ATC if I ever decide to go the route. $218 total shipped. Also ordered a manual oil pump and 5 way push button valve for the PDB.

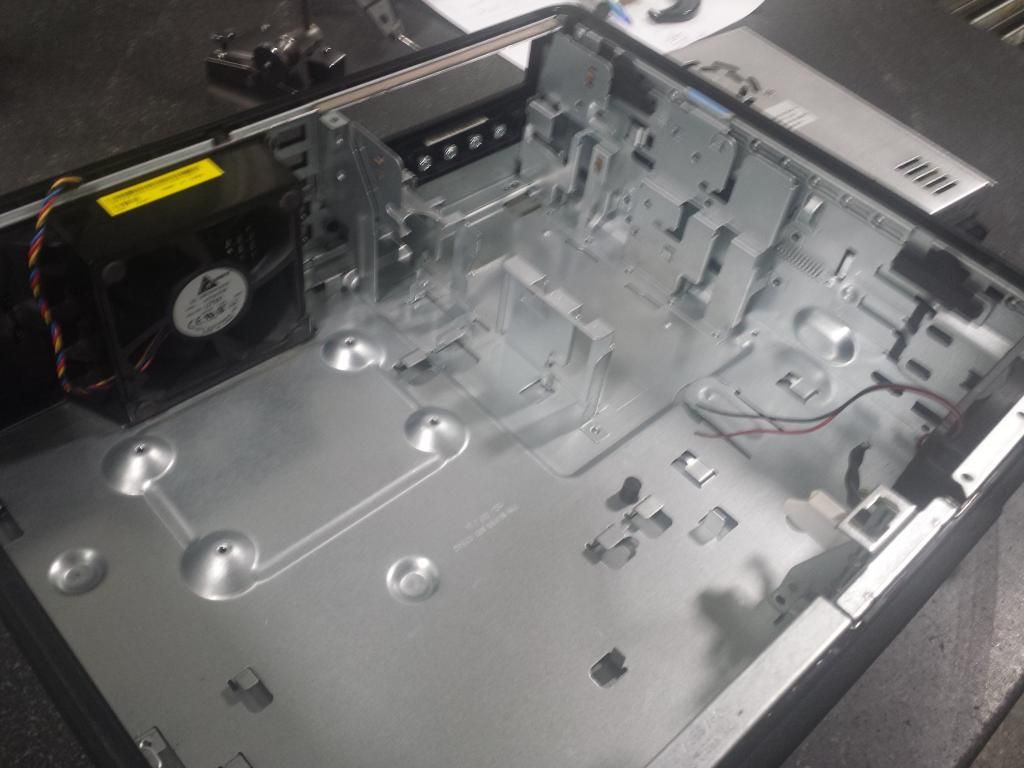

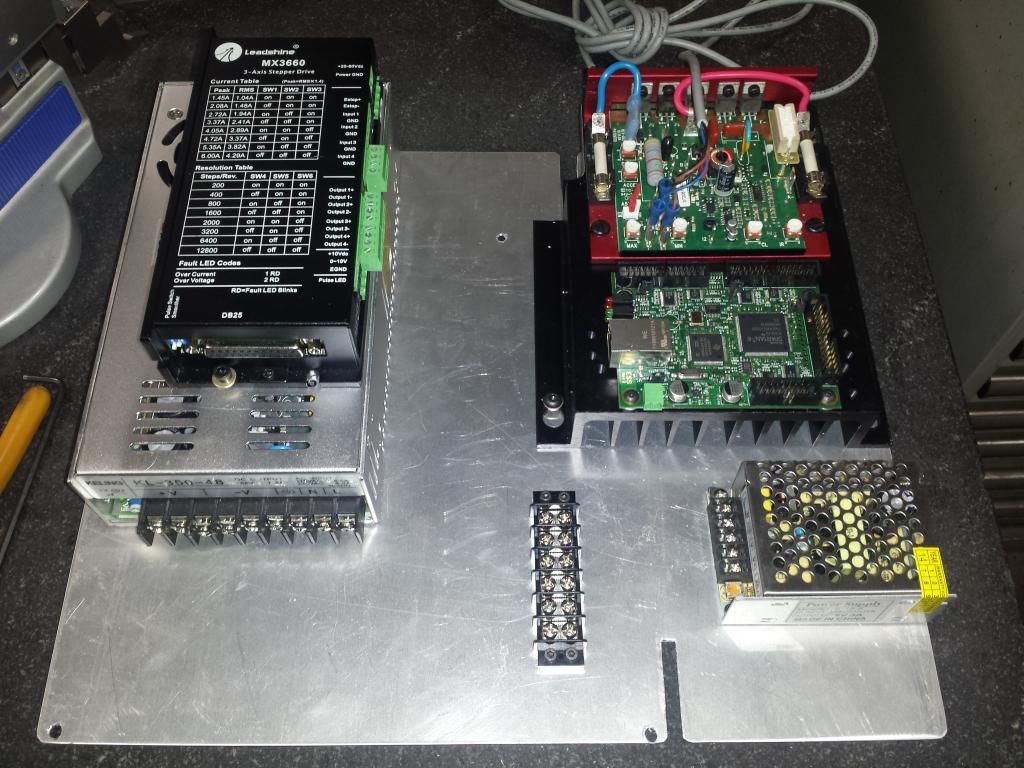

Just pulled apart my make shift electronics board to start laying out my control box.

First mock up:

I have to remove all the brackets so I can make a main board to mount everything to

Need to keep this moving! :wee:

Andrew

-

08-24-2014, 12:37 PM #145

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

Well I redesigned my redesign of the redesign of LacL PDB. Now it puts no pressure on the spindle bearing, like the last redesign, but is also balanced!

So I moved the cylinder closer to the spindle, put the pivot point in the up rights like Hoss' new PDB 3. I kept the same 2.85:1 ration.

Its not the prettiest but it works as I want it to. I may put some spacers under the lift plate to increase the gap between the lever and the drawbar.

Also got my tts style holders from China

Andrew

-

08-25-2014, 04:29 AM #146

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1529

Re: Andrew's G07040 build

Andrew,

Nice work.

Do you have drawings?

I'm thinking of trying a manual version - lever operated.

Cheers,

Nick7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

08-25-2014, 07:26 AM #147

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

I have some very confusing drawings I made on the fly for this. If I were to post them as is most would look at it like

If you want to do a manual one with a lever, I would just follow LacL's original design. You would need the guide brackets, lift plate, top hat, clevis base and a lever for your hand. Along with the needed purchased items.

I think a manual version would put any extra force on the spindle bearings thought?

Andrew

-

08-25-2014, 12:59 PM #148

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1529

Re: Andrew's G07040 build

A manual one can work just the same as yours, but just extend the lever a long way in front instead of having an air cylinder.

7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

08-25-2014, 02:46 PM #149

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

I get what you are saying. But you will be anchored to the ground (you being the mechanical device applying the force) . So just like any other PDB that is attached directly to the machine, any extra force will be applied to the spindle bearings.

in my case it was pushing the quill out of the head.

I'm not saying it won't work, just saying what will more than likely happen.

Andrew

-

08-26-2014, 02:58 PM #150

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Grounding shielded cables?

Grounding shielded cables?

So I have shielded cables for my steppers. I am thinking of using the GX-16 style connectors on my control box. Can I ground the shielding to these metal plugs?

Here is the cable I am using and here are the 4 pin connectors I want to use.

Or maybe I should go for 5 pin connectors and use the 5th pin for grounding?

Please chime in o great forum co-members, I need someone with know on wiring. Still very much a noob on this topic!

Thanks,

Andrew

-

09-05-2014, 08:14 AM #151

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

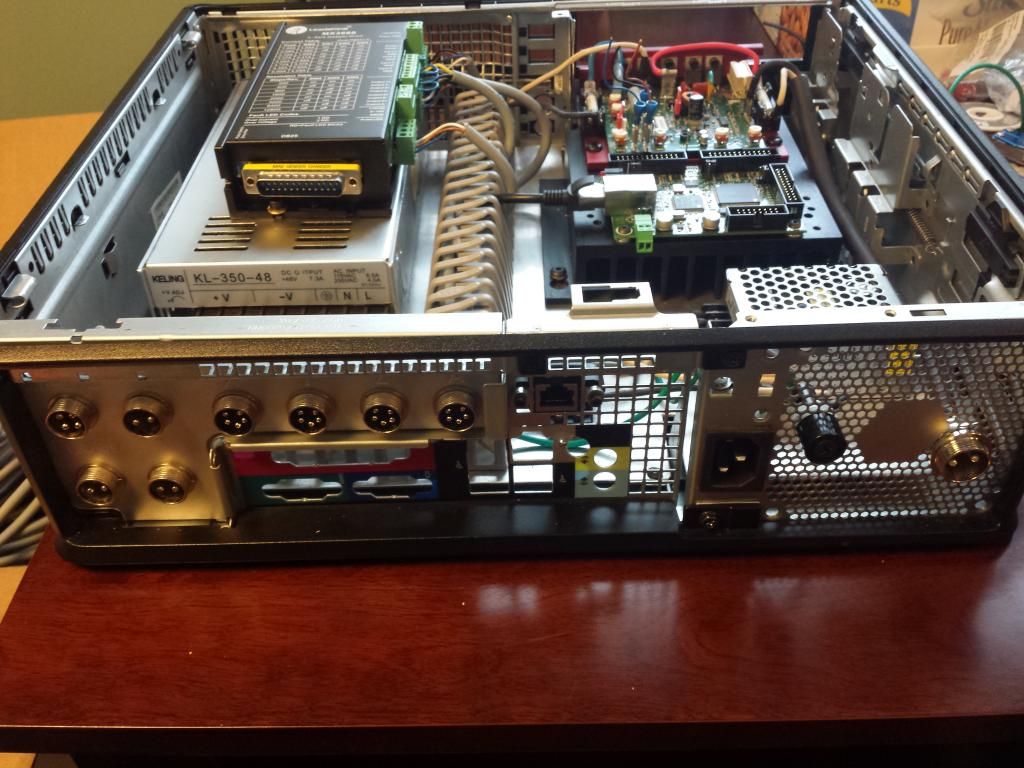

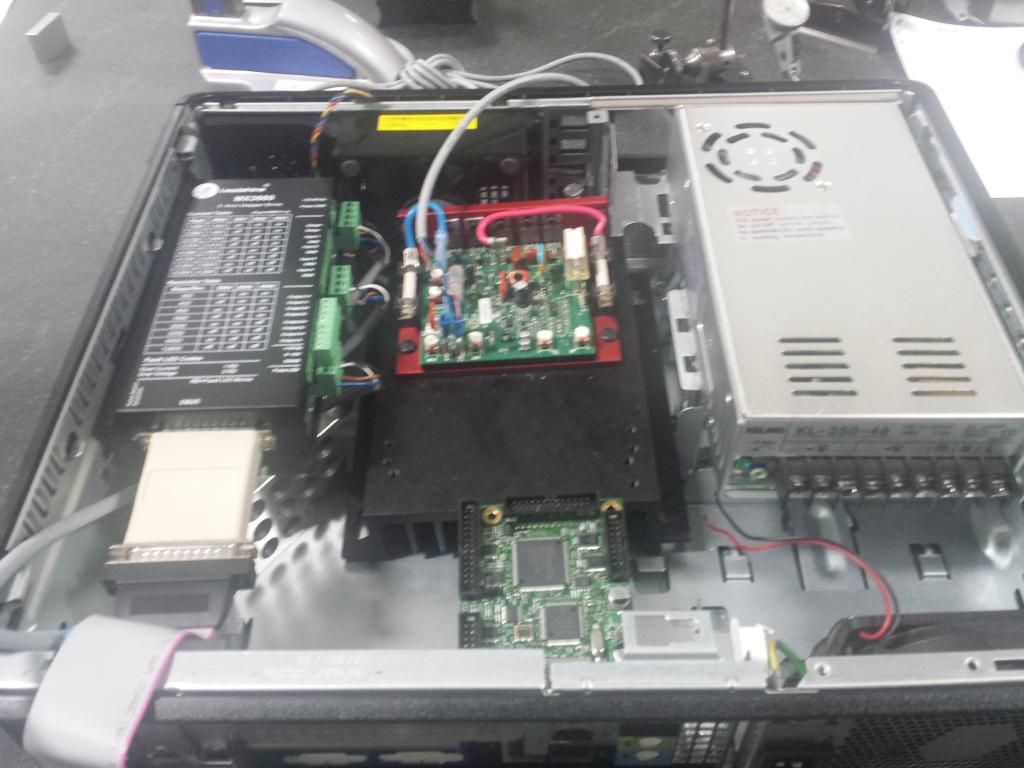

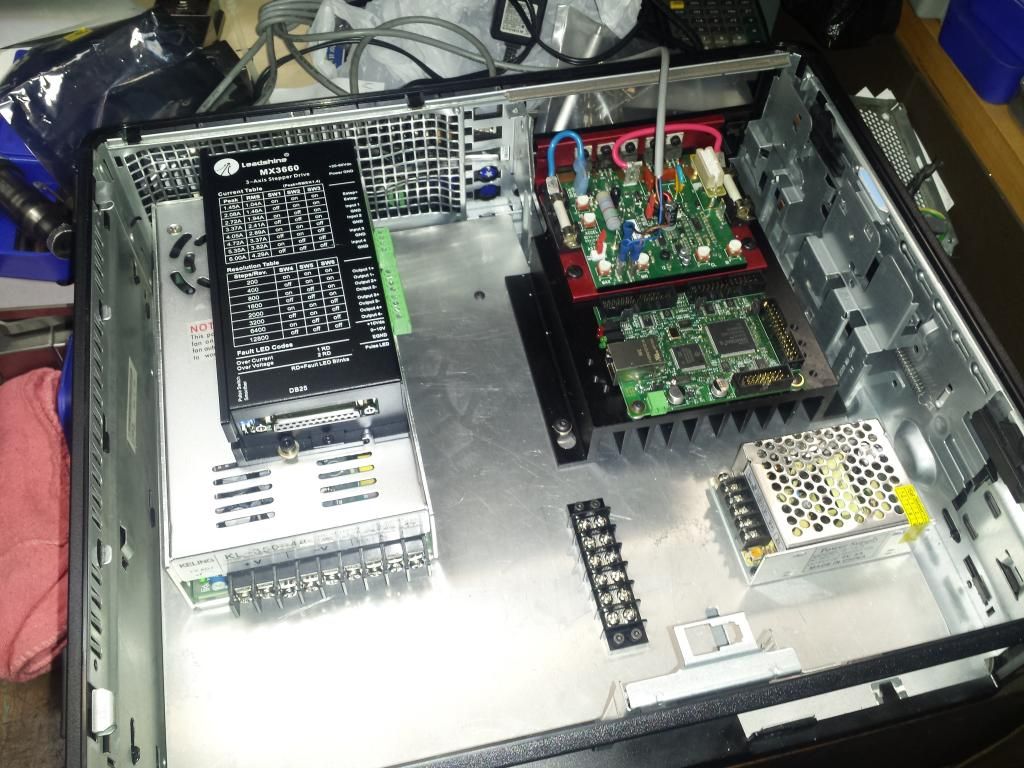

Got the electronics fastened down to the base plate tonight.

And it in the computer case I sourced from work.

It's kind of a snug fit but it all clears.

I plan to run a cable duct between the big PSU and kbmm heat sink toward the terminal bar and then a run in front of the big PSU. in front of the big PSU is where all the motor and limit connectors will be. Power coming into the box by the small PSU. I took the computers PSU apart to reuse the back portion .

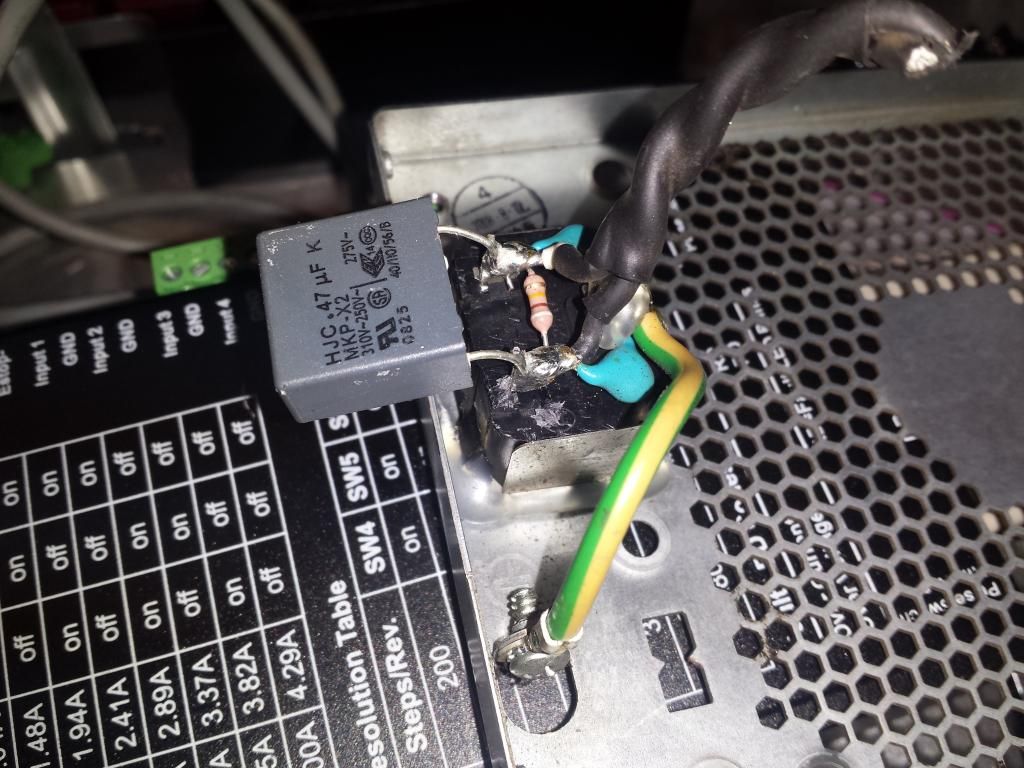

Speaking of which, why is very prong connected to each other in the pic below? I can just rip all this stuff of right?

Andrew

-

09-06-2014, 12:25 AM #152

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 1091

Re: Andrew's G07040 build

Hi,

A couple of issues you may (or may not) experience with your setup.

1. You have your stepper drive mounted to the top of the power supply, obscuring half of the vent holes for the fan directly below it. This may cause overheating of the power supply, cause the fan to run continuously. Also the heatsink of the stepper drive will be heating up the power supply case exacerbating the problem.

2. The Smoothstepper is mounted adjacent to the KBIC motor controller.The KBIC emits EMI which may interfere with the SmoothStepper as it is so close.

Cheers,

Peter-------------------------------------------------

Homann Designs - http://www.homanndesigns.com/store

-

10-19-2014, 01:46 PM #153

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

-

10-20-2014, 03:35 AM #154

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 220

Re: Andrew's G07040 build

I know this has already been mentioned, but I don't think it is a good idea to mount your stepper drive on top of your power supply, or mount your controller right next to your DC drive for your spindle motor. I would buy a larger computer case off of ebay and play it safe.

-

10-20-2014, 04:06 AM #155

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: Andrew's G07040 build

phomann is pretty experienced in electronics. Check out his products if in doubt. Noise problems are hard to find. If he is giving you a warning, there is probably a reason why.

Btw I run one of his speed control interfaces. He has helped me in times of despair.

On another note, if you think that 5 pin is difficult wait til you pop the fuse in that MX3660, it runs an SMD fuse. Can you say small? Dont ask me how I know.A lazy man does it twice.

-

10-20-2014, 05:20 AM #156

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

Thanks for the input. Given where I'm at with wiring this thing up, I'm just going to give it a go and do some testing, it only needs power leads from the PSU's to the ESS \ MX3660 and the 0-10V from the MX3660 to KBMM.

Who knows how long it will take before that happens though

If there are issues it should show right away right? What would you guys expect to see? Jumpy steppers? False limit signals?

Andrew

-

10-20-2014, 12:30 PM #157

Gold Member

Gold Member

- Join Date

- Nov 2009

- Posts

- 4415

Re: Andrew's G07040 build

I would suspect false limit triggering.

A lazy man does it twice.

-

10-21-2014, 07:21 PM #158

Gold Member

Gold Member

- Join Date

- Aug 2010

- Posts

- 630

Re: Andrew's G07040 build

What is the thread size on the elbo's that go into the ballscrews and the saddle? I need to order my fittings and I don't want very large ones.. I've found metric 4mm and 6mm, and 10-32, 1/4 NPT.. and a few 1/8 NPT.

Thanks, ConnorInner Vision Development Corp. - http://www.ivdc.com

Website Design & Development. Shopping Carts, SEO and more!

-

10-21-2014, 07:55 PM #159

Registered

Registered

- Join Date

- Sep 2012

- Posts

- 323

Re: Andrew's G07040 build

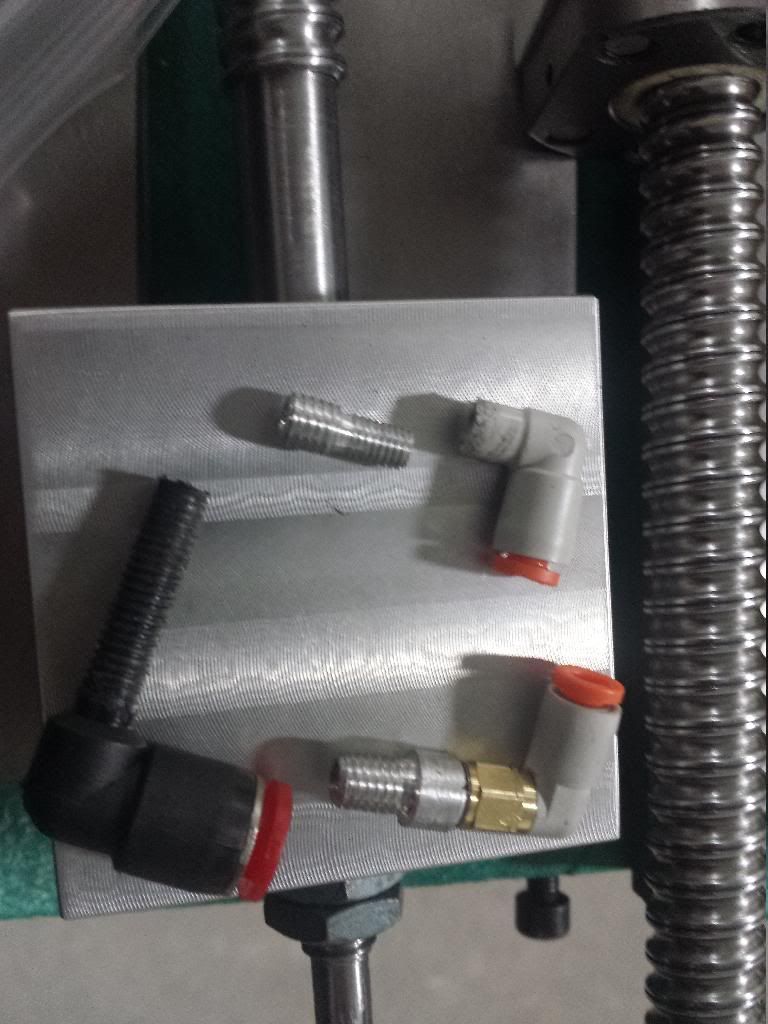

The china c7 ball nuts have a m6x1 thread in them, not the easiest fitting to find. For the Y nut I used a 5/32 elbow with a 10-32 thread on it and made an extension \ adapter that has a 10-32 female and a M6x1 male. for the X I used a 5/32 elbow plugin reducer. I cut off the straight part and made an threaded part that was m6x1 on one side and 10-32 on the other. Y? because I like to make things difficult!

On the saddle I used 1/16 NPT fittings Link Link

For the Z I used some fitting from Arc Euro Trade

If I were to do it again, I would try to use fittings from Arc Euro Trade for the X and Y ball nuts.

Hope it helps,

Andrew

-

10-21-2014, 10:24 PM #160

Gold Member

Gold Member

- Join Date

- Aug 2010

- Posts

- 630

Re: Andrew's G07040 build

Looking at what they have..

Looks like they have a 90degree elbow going to M6x1.0 male to M8x1.0 Female.. The M6x1 part will work.. but.. I wonder if the elbow would fit. Trying to come up with a bill of goods for my setup. I've not done any machining yet. Will work for the Z-Ball screw cause that's what your using. I don't see any T's Just junction bars.. Which I guess a 3 Way bar IS a T.. Hmm..

Looking at 20140714_113729_zpsqohfqnoq.jpg Photo by wiggles84 | Photobucket Were do you go into the saddle on the NEAR side.. I see where you go into it on the far side. Looks like you eliminated T's and went with all direct connections to the manifold. I'll have to think about this...Inner Vision Development Corp. - http://www.ivdc.com

Website Design & Development. Shopping Carts, SEO and more!

Similar Threads

-

Andrew's G0704 CNC Conversion

By andrew2085 in forum Benchtop MachinesReplies: 12Last Post: 01-21-2013, 06:04 PM -

Mint's Build Aluminum/Steel Build thread.

By FreshMint in forum Maintenance DIY DiscussionReplies: 0Last Post: 10-31-2011, 04:18 AM -

Newbie - To build or not to build Router/Plasma Table

By dfranks in forum Waterjet General TopicsReplies: 10Last Post: 04-08-2011, 05:16 AM

Reply With Quote

Reply With Quote