A little more progress I got the other side of the Z plate installed. I am very happy with the rigidity and accuracy. Working with setting up touch probe now. Relocated a part and did some finish cuts finish and size was fantastic. Better than the old Bridgeport at where I used to work as far fit and finish not as rigid as that of course. I think now I'm going to need a little more RPM on spindle I have plenty of torque so I'm going to do some work on pullys. I originally didn't want to push the X2 bearings but a lot of people here are running them up to 6500 rpm I will try for something around that area.

Thread: Scratch build small mill

Results 41 to 52 of 52

-

10-10-2013, 11:43 PM #41

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 97

-

10-11-2013, 12:18 AM #42

Well, if you toast the bearings it will be a good time to see about upgrading them.

Bob La Londe

http://www.YumaBassMan.com

-

10-11-2013, 10:23 AM #43

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

I quickly wore out the original X2 bearings at 6600 RPM. Probably about 4 months in running 6 and 7 days a week.

I bought some from McMaster Carr and then from VXB. Both sources reasonable on cost. Just over $20 a pair IIRC.

I get a good year out of those before I start seeing a little too much runout.

Pretty much in production mode though. For a hobby mill, you can probably not even worry about wearing them out.

Looking good and keep us updated. It's always nice to see some home made ingenuity. Lee

Lee

-

10-11-2013, 02:32 PM #44

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 97

leeway do you remember the bearing # from vxb. I am so glad it came out as rigid as it did. Those people who posted earlier really had me worried and anxious. It is way more rigid than the X2 I had even with all the Z support I added and even way more rigid than a X3 a friend of mine had. Z deflection front to back with a hefty push is .001 and side to side .002. And I weigh 300 pounds I am very happy and little bit sore from drilling and tapping so many holes by hand

-

10-11-2013, 04:36 PM #45

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Post #148 in my build thread here has links to the bearings I use.

http://www.cnczone.com/forums/vertic...l_build-4.html

Apparently these are different bearings or the RPM ratings have changed since I bought mine last.

Still good enough ratings for our machines.Lee

-

10-12-2013, 03:00 PM #46

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 97

-

10-23-2013, 01:07 AM #47

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 97

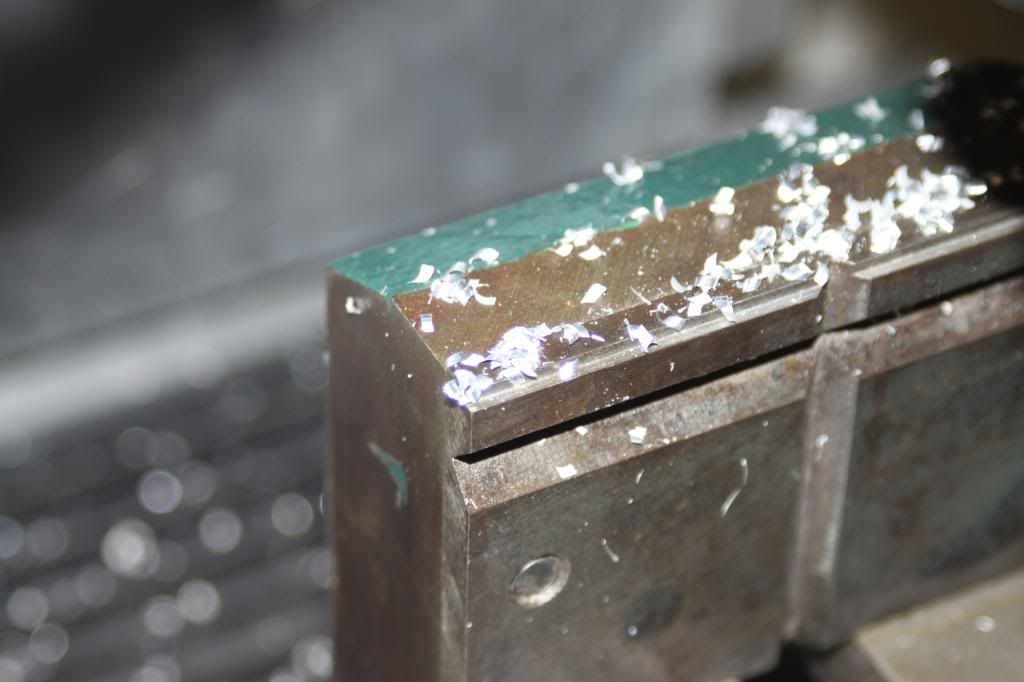

Machine is up and running I don't want to say finished because I don't think they ever are . Got my touch probes for Z and edge finding set up and calibrated the axis. Cuts pretty good here are a couple pictures the one of the chips shows good size and shape. Cutting aluminum 6061 with 5/16 end mill .060 doc 20 ipm 3000 RPM with a 10 ipm plunge

-

10-23-2013, 10:02 AM #48

Member

Member

- Join Date

- Dec 2007

- Posts

- 2134

That's awesome! You must be pretty damn pleased with what you've built!

cheers, IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

04-28-2014, 03:19 PM #49

Registered

Registered

- Join Date

- Apr 2013

- Posts

- 97

Re: Scratch build small mill

Despite all the naysayers it's been months of operation now this little machine is fantastic way stiffer sturdier than I thought. I've made countless parts and piles of chips works flawlessly I couldn't of been happier with the outcome. In the middle of building it I was really worried I just want to post this to say. The idea of a large angle plate is a good idea for z axis and bolted aluminum plates work fine in case somebody else's thinking of building scratch

-

04-28-2014, 03:28 PM #50

Gold Member

Gold Member

- Join Date

- Jun 2004

- Posts

- 6618

Re: Scratch build small mill

I never had a doubt.

Congrats on getting it completed and working. Excellent!

Lee

Congrats on getting it completed and working. Excellent!

Lee

-

04-28-2014, 04:53 PM #51

Re: Scratch build small mill

I always thought it was a nice intermediate design. I am glad its working for you. Just FTN (for the naysayers) Taig is a decent small mill (light cutting only) and its a composite steel and aluminum machine with a nice steel backbone. XiMotion/MaxNC is an all hard anodize aluminum machine with dovetail construction and it works fine. No you aren't going to hog out huge gobs of metal with either machine, but they are decent light duty machines for bench top hobbyists.

I think this build is a nice intermediate idea. Probably a solid step above a Taig. No, its not a Haas or Fadal or a Hurco, but its not a toy either.

Good job. I would love to see some video clips of this thing winging through some of your better cuts.Bob La Londe

http://www.YumaBassMan.com

-

04-29-2014, 12:51 AM #52

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 2151

Re: Scratch build small mill

Very cool

I dig your computer control workstation, Makes me want to add a stop button.

Keep up the great work.

Also

you guys ever look at the work metalmodellbau guy does with his bench mill. A great example of how skill will go long way!

Eine Kleinfräsmaschine, oder Zerspanung auf dem Desktop

Need to use translator or I do anyway Some amazing work imho.

Some amazing work imho.

md

Similar Threads

-

Small mill build X2 spindle

By dick cnc in forum Vertical Mill, Lathe Project LogReplies: 7Last Post: 10-23-2013, 12:42 AM -

Looking to build a small table-top CNC mill

By Particle in forum DIY CNC Router Table MachinesReplies: 9Last Post: 10-05-2011, 03:55 PM -

Considering a (first) machine build, a small desktop mill

By footloose in forum Open Source CNC Machine DesignsReplies: 6Last Post: 05-25-2010, 07:12 AM -

Advice on Small CNC Mill - From Scratch or Pre-Built?

By DrCNC in forum Benchtop MachinesReplies: 7Last Post: 11-30-2006, 01:29 PM

Reply With Quote

Reply With Quote