im building a small wankel rotary project for my ME course

im trying to code up the best way to mill out the housing shape....

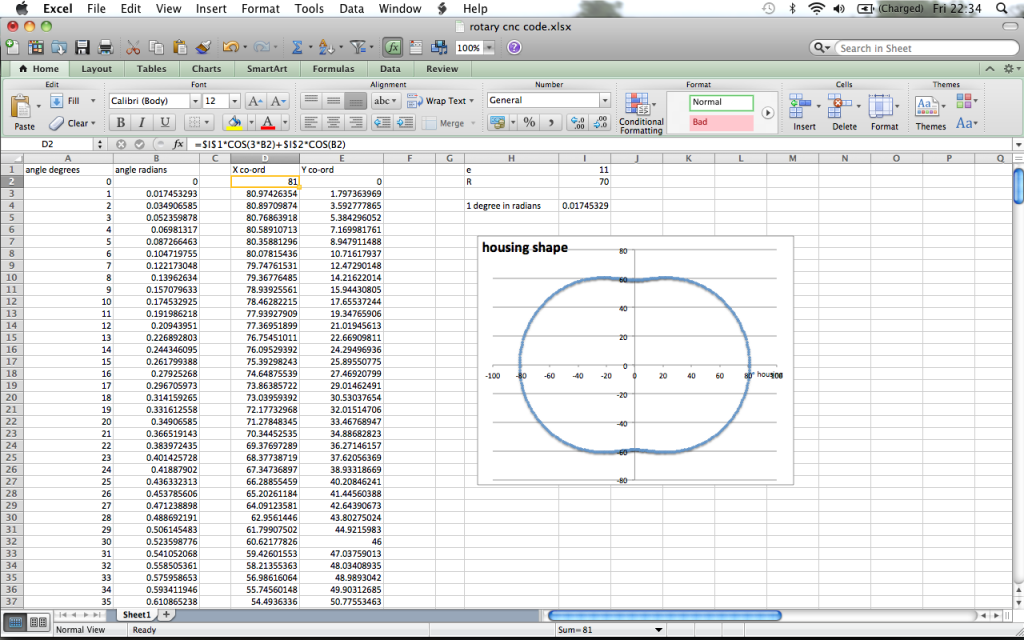

i was planning on just following X and Y co-ord but it will leave a jumpy jagged edge i think ?

maybe there is a pocket code i can use that allow be to input my parameters and follow the shape to its constraints?

below is the excel spreadsheet for the codes....360 x and 360 y points.....

Results 1 to 5 of 5

-

03-06-2014, 06:29 PM #1

Registered

Registered

- Join Date

- Oct 2013

- Posts

- 13

irregular shaped pocket HASS CNC mill

-

03-06-2014, 06:48 PM #2

Gold Member

Gold Member

- Join Date

- Jan 2006

- Posts

- 2985

You should use arc segments (G2, G3) wherever you can. The control will interpolate the arcs as precisely as the machine is capable. If you cannot create the entire shape from arcs, I'd suggest CAM.

-

03-06-2014, 09:04 PM #3

Registered

Registered

- Join Date

- Oct 2013

- Posts

- 13

the shape follows a function....its not really as arc or radius that can be meausred.....

i basically have 360 points that i can traverse through on a G01 and take the middle section that is left with a circular pocket or something

-

03-06-2014, 10:45 PM #4

Well that may be true but when you establish a min max error (ie + - .005) I am betting that the pocket can be described as several arcs with tangential connections.

I have made prototypes for wankle motors in the very distant past and NONE of the drawings I received were functions.

My bet is there is an allowable deviation from the equation (deviation from perfect) and that is what you need to determine.thanks

Michael T.

"If you don't stand for something, chances are, you'll fall for anything!"

-

03-07-2014, 12:10 AM #5

Gold Member

Gold Member

- Join Date

- Jan 2006

- Posts

- 2985

A 1 degree resolution is going to give you a faceted pocket. If you are stuck on using linear moves, I'd suggest solving your equations at .1 or even .01 degree intervals. The length of your linear moves should be on par with the resolution of your machine to get the truest representation of your profile.

Using all linear moves your code is going to be thousands of lines long and you may run into a blocks/second processing problem. You can get virtually the same shape using much longer arc segments and have maybe only a hundred lines for the entire profile.

Similar Threads

-

CNC RF-45 Vs. Hass Mini Mill

By galaxyngc1672 in forum Benchtop MachinesReplies: 4Last Post: 08-11-2012, 06:08 AM -

Possible to setup a default Pocket Setting? i.e. Offset Pocket Out/.5" Roughing Mill/

By 777funk in forum BobCad-CamReplies: 1Last Post: 11-30-2011, 07:51 PM -

Custom shaped mill tools in SprutCAM 7.08

By Live in forum SprutCAMReplies: 3Last Post: 04-21-2010, 11:37 PM -

Hass 5 axis Mill

By Integrexman in forum VideosReplies: 2Last Post: 07-25-2009, 08:28 PM -

looking to buy USED HASS CNC mill

By H_U_S_S_A_M in forum Want To Buy...Need help!Replies: 0Last Post: 04-23-2008, 10:46 PM

Reply With Quote

Reply With Quote