Does anyone still have the KTK manual and the maintenance course notes? Would be a great help. Thanks in advance.

keith

[email protected]

Results 41 to 48 of 48

-

11-29-2020, 08:09 PM #41

Registered

Registered

- Join Date

- Dec 2017

- Posts

- 10

Re: bridgeport interact 4 spindle drive

-

01-08-2021, 07:50 PM #42

Member

Member

- Join Date

- Nov 2016

- Posts

- 16

Re: bridgeport interact 4 spindle drive

Thanks

:cheers:

-

01-08-2021, 07:52 PM #43

Member

Member

- Join Date

- Nov 2016

- Posts

- 16

-

01-23-2021, 07:29 AM #44

Registered

Registered

- Join Date

- Dec 2017

- Posts

- 10

-

01-23-2021, 03:00 PM #45

Member

Member

- Join Date

- Apr 2005

- Posts

- 460

Re: bridgeport interact 4 spindle drive

Maybe off track here but could the problem be a lock out in the control like the BTC does when the way lube is low or the switch in it is defective? It was too much trouble to have a light to display when the oil was low or a fault code displayed and the machine stops at the next tool change without telling you of any fault!! Wont move power down restart no help Add oil and presto its up and going would be a nice feature since the Bejure is hidden inside a cabinet. Just a thought . Keeping old machines running is almost as big of challenge as getting help out of new machine dealers. over the last forty years I have bought many New & Used Machines and most of the time the sales rep/service guy disappears once He gets his commission check , until he thinks you are looking for something new. Many things can be fixed by talking with other owners Thank You CNC Zone for the platform to do so .

-

03-07-2021, 02:55 PM #46

Registered

Registered

- Join Date

- Jan 2005

- Posts

- 1121

Re: bridgeport interact 4 spindle drive

manuals

-

09-10-2023, 02:35 PM #47

- Join Date

- Sep 2023

- Posts

- 2

I have bridgeport intract 4 with 151 control

My issue is when i give spindle speed 500 and give the command M03 so spindle run but when i ups or down spinlde dimmer. Spindle takes so high speed.

Please help me i am in trouble

-

09-17-2023, 11:32 AM #48

- Join Date

- Sep 2023

- Posts

- 2

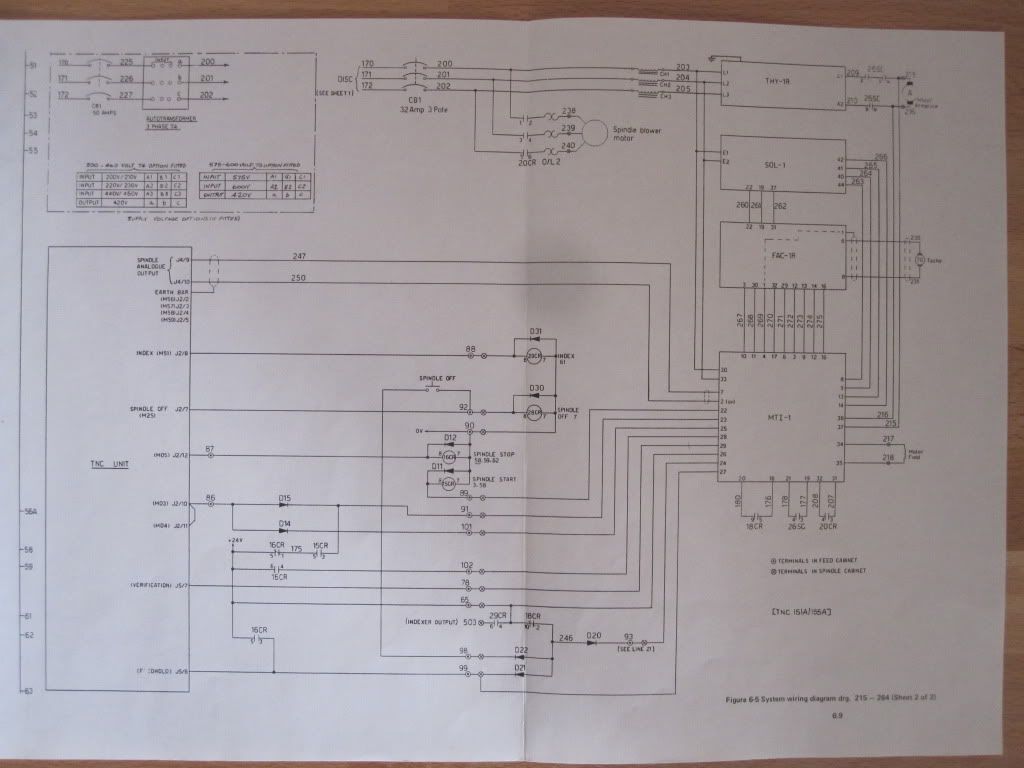

Please give me the wiring diagram of contraves spindle drive with bridgeport intract 4 series 2.

My email address is [email protected]

Similar Threads

-

Bridgeport interact 4 - KTK drive

By luismlgomes in forum Bridgeport / Hardinge MillsReplies: 1Last Post: 12-13-2018, 03:26 PM -

Bridgeport Interact 1 Mk II - Ktk Drive Problem

By palikalsi in forum Bridgeport / Hardinge MillsReplies: 3Last Post: 03-23-2015, 12:50 PM -

Bridgeport Interact 4 spindle drive fault!

By foolmaker in forum Bridgeport / Hardinge MillsReplies: 5Last Post: 01-14-2009, 01:51 PM -

Looking for Bridgeport Interact 412 Spindle 10K

By RMARCH in forum Bridgeport / Hardinge MillsReplies: 1Last Post: 03-12-2008, 05:09 PM -

Bridgeport Interact drive motor test - will this work?

By swarf_rat in forum Bridgeport / Hardinge MillsReplies: 6Last Post: 03-10-2007, 12:11 AM

Reply With Quote

Reply With Quote

Now ive been lucky enough that one of the forum members kindly sent me the docs for the ktk drive ( thank you mr Gamble) but i wish it had been easier This is a link to the KTK docs that i now have as well as my manual

Now ive been lucky enough that one of the forum members kindly sent me the docs for the ktk drive ( thank you mr Gamble) but i wish it had been easier This is a link to the KTK docs that i now have as well as my manual  Happy fixing

Happy fixing