Hello,

Let me introduce myself. My name is Jef from The Netherlands. And interested in buying my first cnc machine.

Making myself is out of the question, dont have the tools to build one. So then i started getting information on the web.

My first machine i had my eyes on was the Shapeoko, but quickly knew this machine would not furfil my goal, to mill hard woods and aluminium sheet, so i continued my search.

Then i came across the OX CNC, sort of Shapeoko with heavier alu extrusions and delrin solid wheels. Also this machine is big and also not very rigid. More then shapeoko but still not strong enough with what i wanted to do with it properly.

Further investigation brought me to the Chinese made 6040's series, like carvingcnc and many other clones on different websites like ebay,aliexpress etc...

Well...still better then previous machines but then limited by the cutarea still not big enough for my goal.

At this moment i had contact with different chinese suplliers and especially my mind focused on two brands, named QuickCnc and Stepmores.

They bot sell the 6090, but with slightly differences in construction and electronics.

Quickcnc K6090T got a solid bedframe, but the toptable is not Aluminium and they use 542, probably leadshine clones stepperdrivers, along with the AutoRich DSP controlsystem.

This machine got Hiwin taiwan square lineair railes only on the Y axis, sbr20mm round supported shafts on Y and Z and uses ballscrew 1605 on all axis. Z guide looks solid with the attached 1.5kw watercooled motor.

Stepmores SM-6090 overall build impression is very nicely finished. Has sbr25mm supported round shafts on the Y axis and X axis, 16mm on the Z. The X,Y and Z mounted with 1605 ballscrew. And got a solid looking aluminium tabletop extrusion profile. Controller also 542 clones leadshine, but usb/mach3 card.

The difference on used electronics is not too important, can easily be changed myself with minimal costs.

Can someone tell me which one ,construction wise is the better choice to choose? And also why?

Really appreciate your comments on this question!

Greetings,

Jef from The Netherlands.

I attached a few pictures too compare

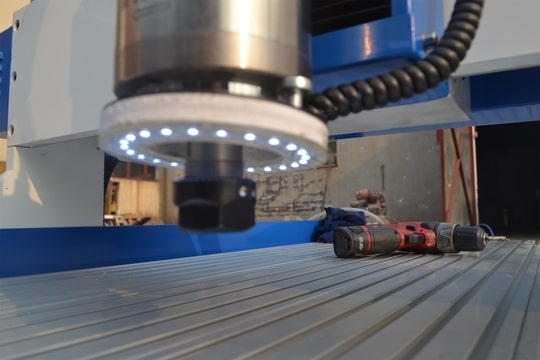

Quickcnc:

Stepmores:

Results 1 to 13 of 13

-

06-08-2014, 01:07 PM #1

Registered

Registered

- Join Date

- Jun 2008

- Posts

- 0

6090 from China. Stepmores versus Quickcnc

-

10-14-2014, 07:22 PM #2

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 114

Re: 6090 from China. Stepmores versus Quickcnc

Hi Jef, I can't advise unfortunately but I am interested in the outcome, did you make a decision in the end?

J

-

10-25-2014, 09:01 AM #3

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 18

Re: 6090 from China. Stepmores versus Quickcnc

This is to anyone thinking of buying a Stepmores cnc machine, do your home work cause you get very little to no literature from the supplier, and I've tried on numerous occasions to get in touch with someone from the company with regards to getting some help getting the thing running. NO joy! I've had the POS for three years nearly, sitting there collecting dust without making a single chip of any sort. I'm very disappointed!! I was also told by the guy I purchased the machine from that all the instructions are in English NOT as he put it Chinglish but sadly they were exactly that Chinglish. Also you have to have a computer running on windows XP or you're screwed.

-

10-29-2014, 10:45 AM #4

Registered

Registered

- Join Date

- Oct 2014

- Posts

- 1

Re: 6090 from China. Stepmores versus Quickcnc

Hi Jef.

I've been researching quite heavily about what machine to buy and I've also narrowed it down to the K6090T from Quick cnc. I've been talking to Taney about it and he's very good at answering all my questions. I haven't found any other information on this particular model except this post so I thought I'd chime in for what its worth.

I was a little put off by the round rails on the x and z axis but I don't think that this will be the greatest cause of inaccuracy on this size machine. It all comes down to what you're expecting.

I'm getting the 2.2kW spindle and the 4th axis rotary addition (not that the DSP controller can deal with 4 axis at a time but I can substitute x or y for the a/c axis. Also considering a gecko upgrade later).

There are a number of reasons I prefer this form machine over the 6100A. Size, weight etc. I'd also like to mount it on an existing (heavy duty) desk to move it around. The losses in rigidity aren't going to effect my work unless I'm really trying to push it hard. Which I'm not. Lastly, completely subjectively, it looks cool.

I'll be finalising the purchase this week so I expect I'll have it December sometime so I'll post back how it all goes then.

If anyone else has any experience with the 6090T I'd certainly like to hear about it!

Cheers.

Jase.

-

08-05-2015, 12:15 AM #5

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 4

Re: 6090 from China. Stepmores versus Quickcnc

Hi Jase

I have just brought the K6090T from QuickCNC. I am currently trialling Vectric's Cut2D program and save my 'tool paths' as G-Code Arcs(mm)(.tap). mm as I'm in New Zealand.

The HHC (hand held controller) seems to read it ok and I can scroll through the lines of code But can't seem to execute the file.

Got an pointers?

Appreciate any help!

Cheers.

Dave.

-

08-05-2015, 11:16 PM #6

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 179

Re: 6090 from China. Stepmores versus Quickcnc

I can get your POS running. Mach3 will run on 64 bit machine but needs either USB smooth stepper or Ethernet smooth stepper. both available from cnc4pc.com. That takes usb/ethernet signal and converts it to parallel. The alternative is to get a USB XHC motion card from Stepper Motor |CNC Router | Laser Machine | 3D Printers For Sale Stepper Motor | Stepper Motor Driver | CNC Router | Laser Machine | 3D Printers For Sale. Around $150 and can control everything including spindle. Runs on 24v as I assume your Chinese machine does. I would throw the chinese BOB away and install this unit and never look back. Smooth stepper and cables will set you back about $200. I can send you a manual for my machines and it will pretty much tell you what you need to know for yours.

Bob

-

08-05-2015, 11:45 PM #7

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 4

Re: 6090 from China. Stepmores versus Quickcnc

Hey Bob

Sorry but I don't know what the hell your talking about there?

Yesterday I had a major break through, As I'm a newbie I just wasn't setting the origin or something correct to start with and now she's ripping into it. So all good. But thank you anyway.

Dave

-

08-06-2015, 05:00 AM #8

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 18

Re: 6090 from China. Stepmores versus Quickcnc

Hey Dave, what did you actually do as I'm having trouble with mine also..

-

08-06-2015, 05:32 AM #9

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 4

Re: 6090 from China. Stepmores versus Quickcnc

I spent the day reading the forum to work out what to do as I had no idea at all and found a guy named 'Rocket67', he is in oz also and spelled out step by step how to set up and execute the file, here is the text I copied

-

Here is how to run a program on the machine -

When you complete the design work and toolpathing in your chosen software, save the data to a LEXAR USB stick.

Fit the USB stick into the top of the DSP Controller and THEN turn the machine on. The DSP Controller will light up and the question " Go to Home" will appear on the screen. This is actually a command. You need to press the OK button. The gantry and spindle will go to the Home position.

Do this even if it is already at the Home position. No machining operation can start unless it is at the Home position.

When operating the machine the first time, you need to set the X/Y Zero point. This is normally top left of the board you are about to router. Mark a starting position in at least 20mm on X and Y Axis that you will normally have the corner of your board to router. Use the same point all the time if possible ( otherwise you have to reset the X/Y Origin.)

Manually move the gantry to the precise required starting point. This is not easy at first. Quick spurts on the correct button will be needed for fine positioning. When the spindle is precisely on the point press the X/Y-0 button. It is now set. Press the Home button.

Next set the Z Zero. With the required bit in the spindle press Origin OK button. Gantry will move to preset X/Y Zero point. Press Z- button to lower spindle to top of board to be routered. Use quick bursts until the bit is just touching the surface of the board to be routered. Then press Z-0 button. It is now set. Press Home button.

You can now run the program. Warm up the spindle for a couple of minutes using the On/Off button. Then turn spindle off using the On/Off button. Turn your dust extractor on and ensure cooling pump is on.

To run program -

Press Run/Pause button. Using X buttons select U Disc File List. Press origin OK button. Using X buttons, scroll through list on screen to required file. Press OK Origin button. The DSP will now show process and travelling speed. Adjust if necessary. We run ours at 5,000mm/min for both process and travelling speed. Until you are used to the different operations of the DSP Controller, if it reads anywhere between 2,000mm/min and 5,000mm/min just press OK button. The DSP will now read the file and if all is well the spindle will start and the machine will router your item and return to X/Y origin when finished, ready for a bit change and turn the spindle off. If you are finished, press home and gantry will return to home position. Then turn machine and extractor and pump off.

- i hope this helps!

I had my designs all ready as EPS files from Adobe Illustrator

imported to Cut2D, then saved my 'tool paths' to G-Code Arcs (mm) (.tap) as that is what I was told my machine ran on.

Once the machine starts on its way it's a little scary but once the piece was cut, you couldn't wipe the smile of my face.

Good luck

Dave

-

08-06-2015, 05:52 AM #10

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 18

Re: 6090 from China. Stepmores versus Quickcnc

Thanks man I'll give it a go! CHEERS..

-

08-06-2015, 05:59 AM #11

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 18

Re: 6090 from China. Stepmores versus Quickcnc

Actually Dave is there code missing from that post?

-

08-11-2015, 01:41 AM #12

Registered

Registered

- Join Date

- Jul 2015

- Posts

- 4

Re: 6090 from China. Stepmores versus Quickcnc

Sorry I didn't get notified about this,

The 'code' is something that is created in the program you use.

I use Cut2D from vectric.com

But I create my vector files in illustrator first as that's what I've worked with for years [graphic design etc].

This can [the vector file] be created in Cut2D or you should be able to with what ever program you decide to get.

Once I import my vector file i.e. .eps file into Cut2D I make a 'tool path' of it and save the 'tool path' to a .tap file.

Thats the file I send to my router. Back in the program if I save the program file it's call something else like a .crv file, but I don't need that for the router, it's only for, say if you need to edit the tool path or whatever.

So I don't even see code. It's all in the .tap file. The router reads it and off it goes.

The code is like making a web page from scratch. It'll take ages to learn, But why even bother when the program does it all for you.

Sorry I'm not very good at putting thing down in words, but I hope your getting closer

p.s. my machine came with some **** program called Type3 and had to run it on windowXP. **** that.

I got a windows 8 laptop [best one for lowest price, as I work on Mac] and brought Cut2D, it set me back another 1200 odd bucks but it's all up to date and no problems and F'n about.

Dave

-

08-11-2015, 02:10 AM #13

Banned

Banned

- Join Date

- Aug 2015

- Posts

- 14

Re: 6090 from China. Stepmores versus Quickcnc

Hello Jef,

Seven from China(wuhan HE laser Engineering Co.,Ltd),we are a Chinese-Russian company which is professional in yag and fiber laser cutting machines,

it can cut stainless steel,carbon steel ,aluminium,copper,brass and many other metals,popular in industrial field,

can be used in elevator,kitchenware,hardware,machinery etc.

Also we have supplied products to bosh,Foxconn and many other branded companies,the quality has been tested.

if anyone you know interest in metal cutting and engraving machine,you can take us into consideration.

Thanks in advance.

Sincerely............Seven

Similar Threads

-

Looking to purchase a 6090 machine from China.

By shawnrw in forum Chinese MachinesReplies: 10Last Post: 10-24-2017, 09:17 PM -

Configure NCStudio for JX-6090 CNC router from China

By julien123 in forum Uncategorised CAM DiscussionReplies: 35Last Post: 06-12-2014, 11:51 PM -

Ease of use.. GibbsCAM versus Mastercam versus BobCADCAM, etc.?

By squale in forum Uncategorised CAM DiscussionReplies: 9Last Post: 01-01-2013, 08:58 PM -

vm-1 versus newer vm10 converational versus g code

By powerstream in forum HURCOReplies: 6Last Post: 07-13-2010, 08:35 AM -

Mister versus flood versus ??? coolant system

By split63 in forum Bridgeport / Hardinge MillsReplies: 14Last Post: 10-02-2006, 11:18 AM

Reply With Quote

Reply With Quote