Hi All,

My Father-In-Law and I recently became aware of CNC router tables while searching for a way to make some custom fence post caps. We both fell in love with the idea of having a CNC router table in the workshop, and set a $2000 budget for a small tabletop unit. As we searched around, it became apparent that neither of us would be happy with a small unit, so we blew the budget out of the water and decided to go with a CRP Pro 48x48. We purchased the parts kit and electronics directly from Ahren (NEMA 23 to keep the spending somewhat under control), and sourced the extrusion from the 80/20 distributor here in Canada.

Cost was the deciding factor for size, and the beauty of the CRP kit is the ease in which we can go bigger with both the table size and motor size in the future.

We were also both new to the concept of 80/20 extrusion, and we thought we would give a go at building the 'legs' out of extrusion as well.

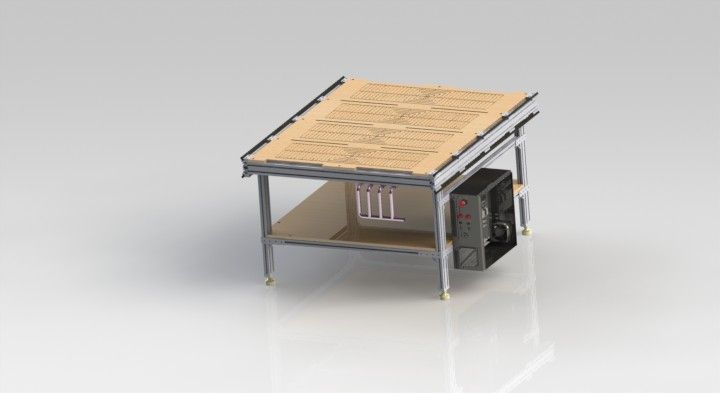

I whipped up a drawing of the base in SolidWorks:

Here it is in real life:

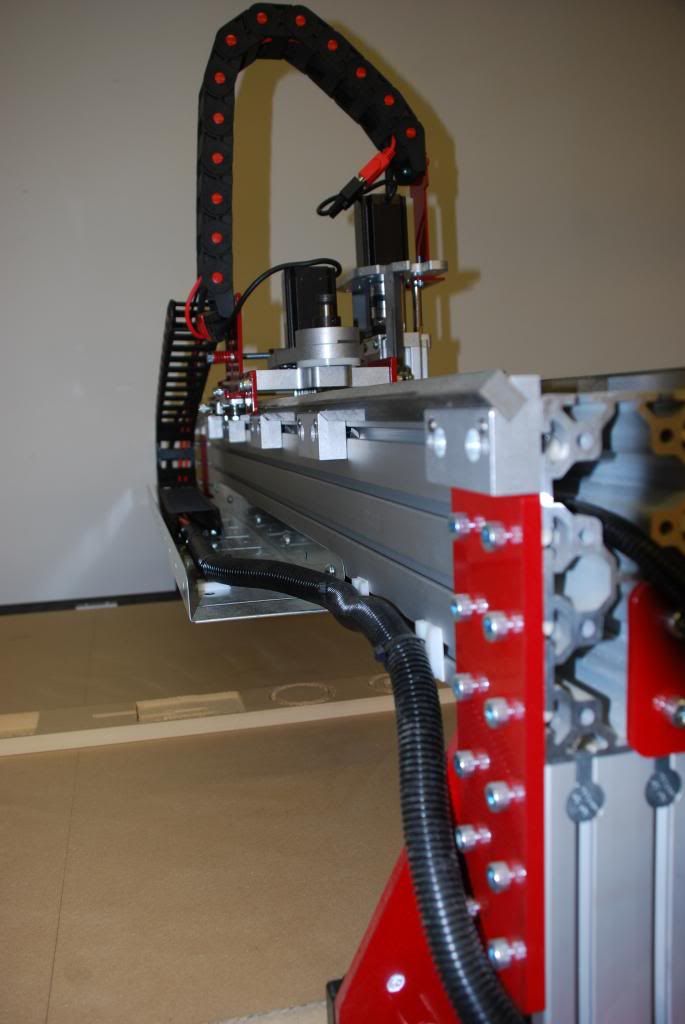

Assembling the actual machine:

This is as far as we've made it to date, waiting for the gantry steel rails to come in before we can continue on.

Total cost including the various shipping fees (but excluding software costs) has come out to around $7000.00 to date.

Results 1 to 20 of 39

-

06-14-2014, 08:46 PM #1

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

A CRP Pro 4848 Build North of the 49th

-

06-15-2014, 12:36 AM #2

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 26

Re: A CRP Pro 4848 Build North of the 49th

That looks nice. I was thinking of using the extrusion for my table and I might use that design. Clean and simple.

How ridged is it? Is there any flex?

-

06-18-2014, 07:35 PM #3

Registered

Registered

- Join Date

- Jan 2014

- Posts

- 60

Re: A CRP Pro 4848 Build North of the 49th

Very nice looking build there! If you don't mind me asking, does that cost also include the PC and TV or just the kit, base, and electronics?

-

06-19-2014, 04:47 AM #4

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

Re: A CRP Pro 4848 Build North of the 49th

It seems fairly rigid, but I will have to reserve judgement on that until I get it running.

The PC and TV I had laying around, and it cost me another $250.00 or so to bring the PC up to snuff.

There is going to be a bunch more to add to the list before this thing runs: Mach 3, an enclosure and various bits and pieces for the electronics, a set of bits to get started with, a SuperPID2 for the router.... and so on. I figure I should have this thing cutting by the $9500.00 CAD mark, and that still doesn't include tool path software. Its crazy how on a project like this the little costs just keep adding up.

On another note, UPS screwed up (big surprise!) and my gantry rails are bouncing around Canada. Probably at least another week until they show up. In the mean time, I slapped together a little enclosure for the PC out of some MDF with furnace filter on each side.

-

07-01-2014, 12:34 AM #5

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

Re: A CRP Pro 4848 Build North of the 49th

Yay! The rails for the gantry came in! They actually came in last Monday, but I had multiple weddings to attend to and was not able to get anything done on the machine until last night.

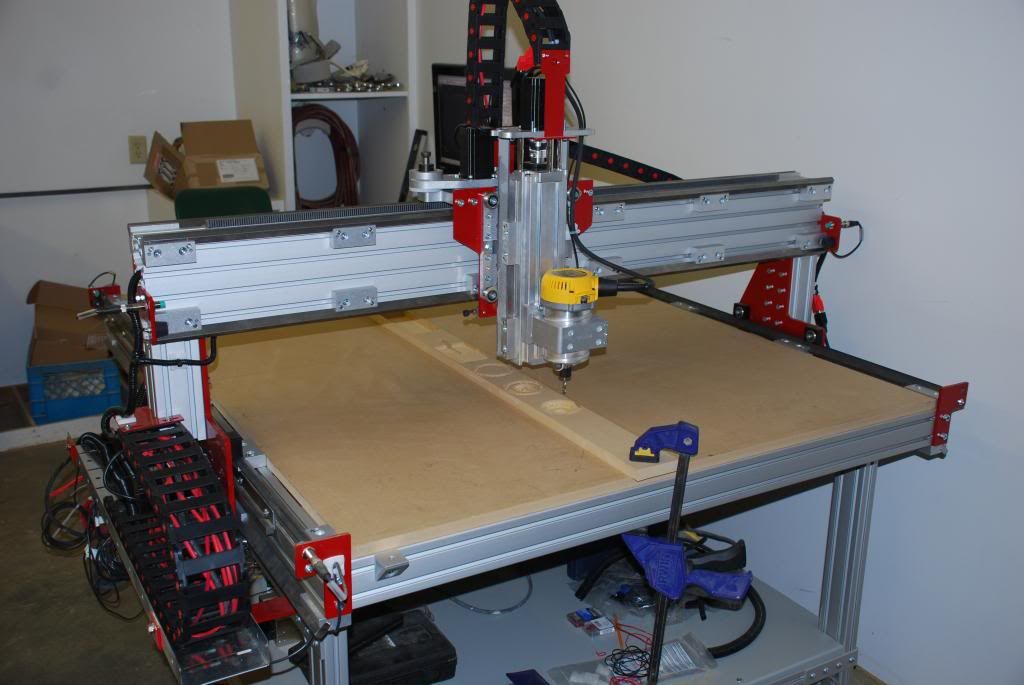

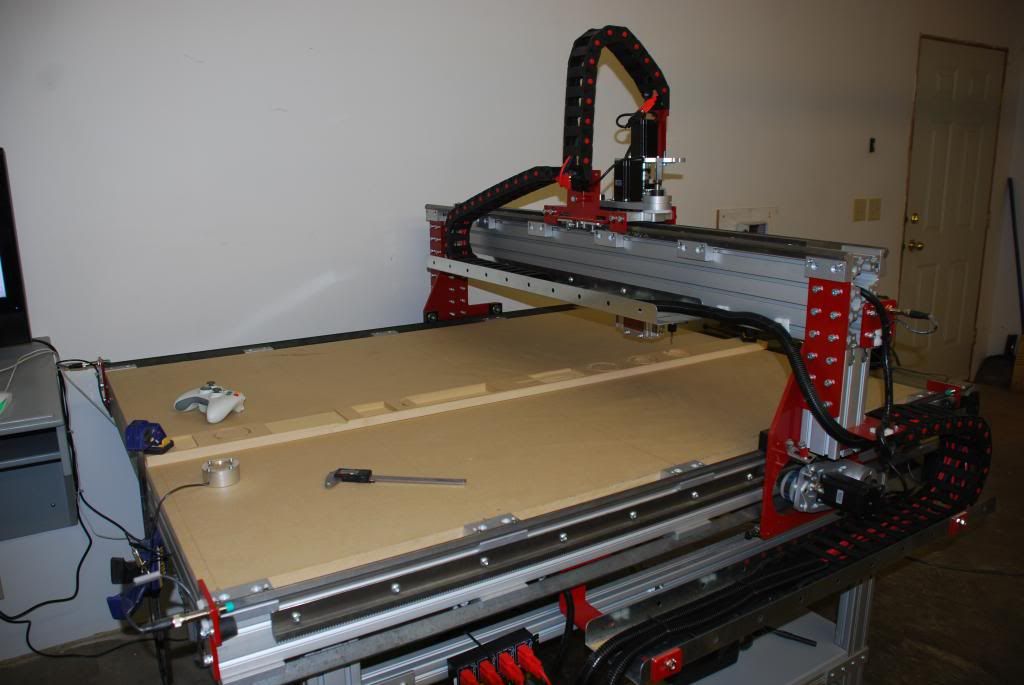

The rest of the assembly went as easy as the previous bit, and it was moving around under it's own power in no time.

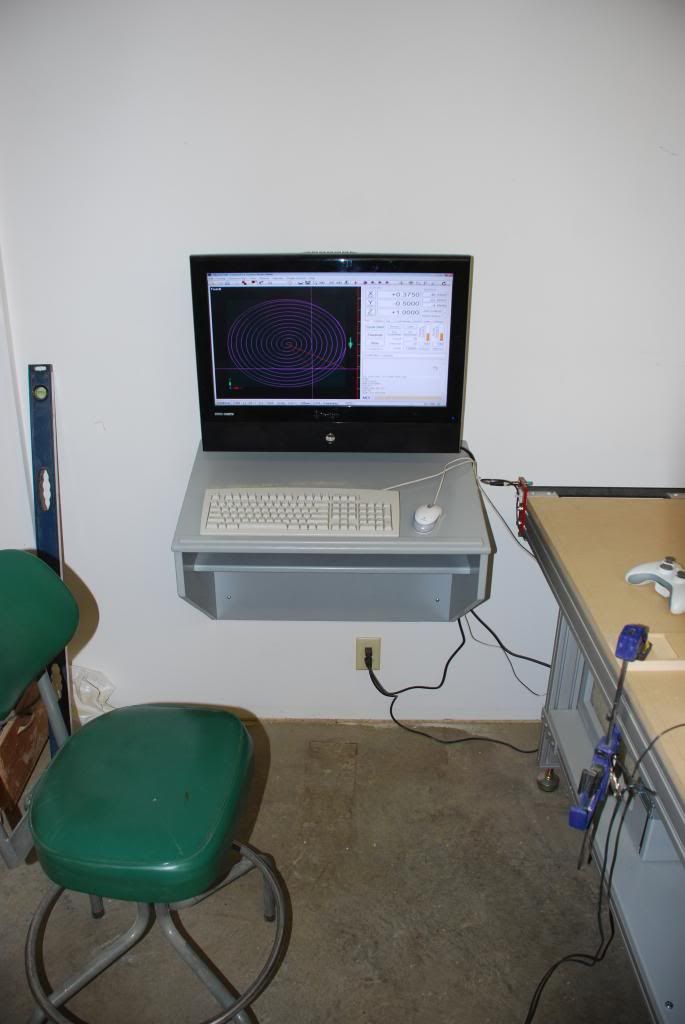

A little workstation I slapped together while I was waiting for the rails:

Assembled and wired:

Front:

Back:

I was pleasantly surprised to find how nicely it ran 'right out of the box'. With the supplied Mach 3 XML file, I was able to run through some of the Mach 3 Wizards and cut some rectangular and circular pockets to within a few thousandths of what they were supposed to be. And that is without even having the spoilboard fastened and leveled, or the stock secured properly!

Now I just need to wire all the electronics up in a permanent fashion, and sort out some dust collection, and the chips can start flying!

-

07-11-2014, 02:02 PM #6

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

-

07-24-2014, 01:12 PM #7

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 3

Re: A CRP Pro 4848 Build North of the 49th

Hi Mobius. Very nice build. I am impressed. I'm especially interested in your base. I am considering a base from extrusion like yours. It seems like it will be a bit expensive initially, compared to a steel base. But I can see earning that back twice when it comes time to mount controls, PC, cable trays, etc. Would you be open to posting a bill of materials of which parts you used for your base?

Thanks,

GBS

-

07-25-2014, 01:50 PM #8

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

Re: A CRP Pro 4848 Build North of the 49th

Sure, I will put one together and post it up soon.

-

07-27-2014, 02:22 AM #9

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 3

Re: A CRP Pro 4848 Build North of the 49th

Awesome, thanks!

-

07-28-2014, 03:03 AM #10

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

Re: A CRP Pro 4848 Build North of the 49th

Here you are.

-

07-28-2014, 03:43 PM #11

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 3

Re: A CRP Pro 4848 Build North of the 49th

Outstanding! Thanks so much. I'll be sure to post a pic when I get underway.

GBS

-

09-03-2014, 02:54 AM #12

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

Re: A CRP Pro 4848 Build North of the 49th

Progress!

I finally got around to cleaning up the mess of components and wires I had strewn around underneath my new CNC, wiring them all into an enclosure.

Ignore the pot dangling from the G540, the last connection of the day was to hook up the VFD output to my Super-PID2, and I mistakenly reversed the V+ and Gnd wires. You know, the two wires it explicitly says not to reverse in the G540 manual or you could (will) fry the VFD output..... I wired the pot back in temporarily so that I can continue to cut while I wait for a new one.

Speaking of cutting; got started on some fence post caps, some storage for router stuff, a wedding present, a sign for my inlaws, and some samples for wedding reception tabletop numbers:

-

09-03-2014, 03:10 AM #13

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: A CRP Pro 4848 Build North of the 49th

Nice work.

Better get a filter on the fan in your enclosure, or it'll be full of dust before you know it.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

09-03-2014, 03:45 PM #14

Registered

Registered

- Join Date

- Jun 2011

- Posts

- 341

Re: A CRP Pro 4848 Build North of the 49th

What sort of information are you displaying on the front mounted display??

-

09-03-2014, 09:03 PM #15

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

Re: A CRP Pro 4848 Build North of the 49th

That is the display for the SuperPID2 router speed controller, it displays the router speed (and temperature if you have the optional sensor).

-

09-29-2014, 03:36 AM #16

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

Re: A CRP Pro 4848 Build North of the 49th

Coles:

- Repeatable loss of steps in the X / A axis (0.008 to 0.012 give or take), Y axis is accurate. Loss of steps occurs even during 'air cuts'. Pretty sure this is a new issue, as a project cut a few days before showed no sign of loss of steps in the X / A axis.

- Checked electrical continuity between various parts of the machine and the electrical ground to ensure static electricity discharge path

- Checked for mechanical binding/looseness

- Checked for Gecko G540 overheating

- Checked electrical connections

- Noticed that at the initial moment of an X-axis move, the slaved A axis seems to be delayed for a fraction of a second causing the gantry to pivot out of square. Pivot motion happens when starting in either direction. After the initial delay, the A axis works fine and at the same speed as the X.

- Checked motor tuning settings, both X and A are identical.

Long version:

After a bit of a hiatus where I worked on a 'paying' project (I say 'paying' because we ended up gifting the project in the end), I started back on some more fence post caps. I had hardly gotten started when I snapped a bit. The bit snapped because I had lost steps on the X axis and it was taking more of a bite than it could handle. I put in a new bit and re-started the file, only to find a loss of steps in the same places.

My first thought was that my Gecko G540 had overheated again (I had a previous problem where after 45 min the Y axis would start wondering off into space, which was solved by adding better cooling for the G540). I checked the case temperature and found it to be only 43ºC.

My next thought was that I was having static electricity problems, but I had excellent electrical conductivity throughout the machine all the way to the electrical ground.

Since the machine has been well broken in by now, I then decided to disconnect the motors and make sure everything was clean and tight. I cleaned off the rail and bearing surfaces where some wood dust had built up and become compacted along the surface. Everything rolled very smoothly with no binding. I reconnected the motors and was greeted with the same loss of steps.

I checked all the stepper drive motor electrical connections, everything seems tight.

Next I started to repeatedly home the machine and send it to co-ordinates in the middle of the table. Once there I would re-zero, home, and then send it back to the work zero co-ordinates. Each time it would be off by 0.008-0.01" on the X axis (Y was fine). While I was doing this, I found that each time I made a movement in the X axis, the gantry would pivot out of square. It seems like the slaved A Axis is delayed by a fraction of a second and it causes the gantry to pivot a slight amount, this amount co-insides with the amount of steps lost. This oddity happens while moving the X axis in either direction.

Things I know I should check but ran out of time today:

- Swap pin assignments and use a different axis drive to power the A slave and see if the problem persists.

- If problem persists, try connecting motor directly to the G540 (right now it goes to a DB-9 bulkhead connector and then through another DB-9 cable to the G540, possible connection issue?)

Those are the only two ideas I have at the moment, any other suggestions or things I may have missed?

-

09-29-2014, 04:20 AM #17

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: A CRP Pro 4848 Build North of the 49th

Make sure the pinions and pulleys are not loose.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

09-30-2014, 01:06 AM #18

Registered

Registered

- Join Date

- Apr 2014

- Posts

- 0

Re: A CRP Pro 4848 Build North of the 49th

As soon as I read your post this morning, it became so obvious it hurt. When I was checking for mechanical issues I had spun the motors/gears by hand and didn't see anything wrong. However, I just finished pulling the belt off that side and sure enough, the motor pulley spun freely. Looks like the pressure from the belt caused it to have enough friction that I didn't catch it initially.

I owe you a beer for that one, thanks Gerry!

-

09-30-2014, 08:52 AM #19

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: A CRP Pro 4848 Build North of the 49th

That issue seems to be super common with the CNCRP machines. I use ample loktite on all the set screws on my machine and hopefully it won't happen to me.

/knocks on wood.

-

10-06-2014, 11:43 PM #20

Company Representative

Company Representative

- Join Date

- Feb 2004

- Posts

- 1086

Re: A CRP Pro 4848 Build North of the 49th

Hi Mobius,

Your machine and the stuff you are making with it are both looking great! It sounds like you figured out your lost motion issue.

In looking at your enclosure pics (nice wiring job, BTW) it appears you have your motor cables running into some ports on the side of the box, and then some other cables going from there to the G540. Are those other cables just standard serial cables? The reason I ask is that our own motor cables are made with 20 AWG wire and 5A rated serial connectors. However, the connectors on most serial cables are only rated for 1A, and the conductors are often 26AWG or even 30AWG wire, which is not capable of sustaining the 3.5A peak current the G540 can put out. Additionally, it looks like you have overmolded connectors going into the G540, so you're probably carrying the current set resistor value through these into the drive. Gecko has had numerous issues with any approach where this resistor isn't right next to the drive, as noise gets picked up on the current set lines and can cause issues in the unit, most notably failing to go into low current mode when an axis isn't moving.

It appears that things are working OK for now (more than OK!), but I have seen standard serial cables literally melt from overheating, so unless these are heavier gauge wire, you may want to consider swapping them out at some point to avoid a failure in the middle of an important project.

Other than that, keep showing us the cool projects you are making!

Best regards,

Ahren

CNCRouterParts

Similar Threads

-

Pro 4848 build

By cbr929 in forum Avid CNCReplies: 21Last Post: 11-15-2014, 11:31 AM -

Pro 4848 build

By cbr929 in forum Avid CNCReplies: 0Last Post: 04-16-2014, 12:50 AM -

Completed Build - CNC Pro 4848

By Gilrock in forum Avid CNCReplies: 0Last Post: 02-07-2014, 06:47 PM -

CNCRP 4848 Prep.

By tangeray in forum DIY CNC Router Table MachinesReplies: 35Last Post: 08-04-2013, 11:44 PM -

Shipping across the 49th

By DSL PWR in forum Community Club HouseReplies: 8Last Post: 08-30-2004, 10:52 PM

Reply With Quote

Reply With Quote