I think the time to Retrofit my mill has come.

Machine is a very sturdy Avon 3000 Bridgeport type mill.

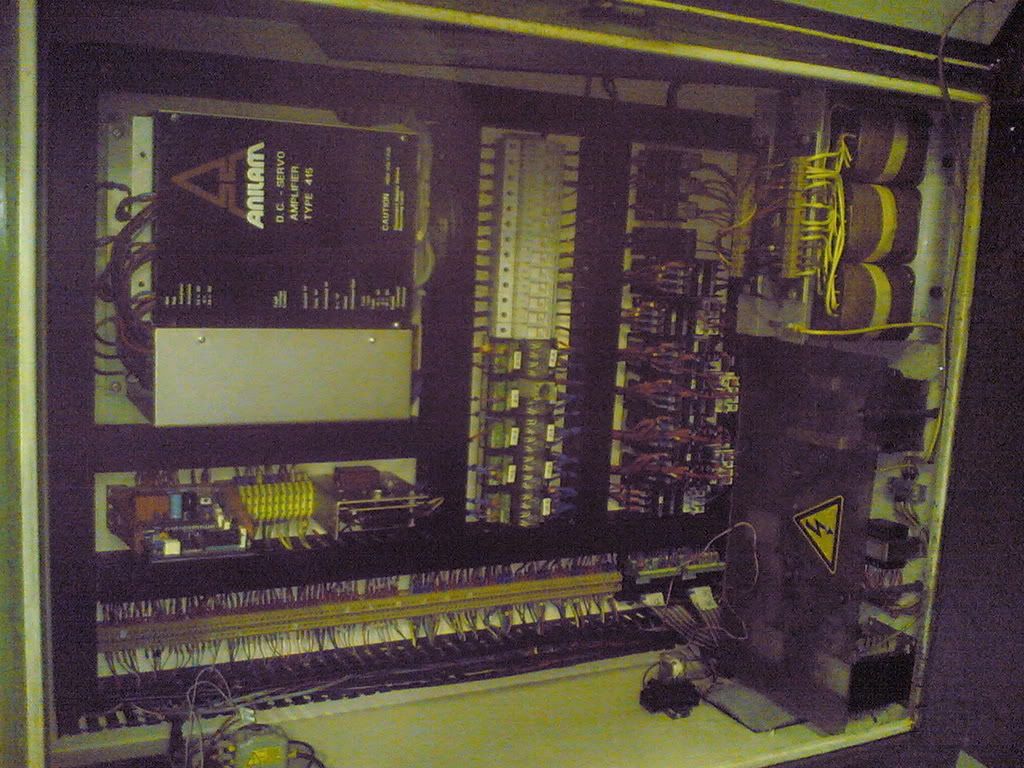

Controller is a Anilam (Crusader) GXM (1988 circa)

Servo system: DC Servo's with encoders and tacho feedback.

Ballscrews on all 3 axis.

OK, so now we get to the problems...

1.Some of the tool registers is currupt and whenever used, would throw the machine out by 10meters or so.

2. The machine is more temperamental than my whife (hang on let me just check if she's in the house)

3. I cannot get it to drip feed, and programs are thus limited to about 2000 lines of code.

4. The controller boards seem to be plagued by dry joints and/or other problems, as on damp days it is touch and go if it would run.

5. Today is one of those days when it does not accept any commands from the keypad. If i wait long enough it would probably start working again, but in the meantime i'm getting really nervous about a project i promised a friend would be finished on monday...

Bottom line is i need a machine i can count on and I just cant rely on this machine to be around tomorrow!

Now for the questions....

1. Would you guys sugest a retrofit or ... what else?

2. I would like to keep the servo's, ballscrews and all the mechanics in tact, as i beleive they are all in good shape, by what about the servo drives? Do i keep them, or do i get a set of geco's or similar?

3. What about the tacho feedback? Desiarable/ required or not?

4. How complicated is it to interface a new (pc based) system to the existing system?

5. Do i need to get a motion controller card, or can the same speed and positioning acuracy be obtained with paralel breakout boards?

6. Any other sugestions/ warnings etc.

I know this is a lot of questions, but i would like to keep downtime as short as possible and i therefore need to know what's going to be involved before i start ripping at the present system.

Thanks

Pieter

Results 1 to 4 of 4

-

06-21-2008, 04:42 PM #1

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 185

Time to retrofit-Anilam Crusader GXM seems to be on it's last legs...

-

06-21-2008, 05:20 PM #2

There is another ongoing retrofit of a Crusader here using Camsoft, but many of the issues are the same for whatever system you use,

Do not use the same drives, practically all current DC drives use Torque mode of operation which means you do not require the tach feedback, (just pull the tach brushes).

The motors are generally SEM or equivalent, 140vDC rated.

There is a learning curve if you have never retrofitted before, and any system you use is going to take a fair amount of time to integrate, depending on your electrical/electronic experience.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

06-24-2008, 11:31 PM #3

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 185

I had a good look at some of the other retrofits going here and decided to give the guys at Camsoft a buzz (via their online request information link)

Now if their product is only half as good as their service, it must one hell of a product. Within an hour from first making contact i've had about 5 emails going back and forth to request and provide info on my current system and shortly after i had my quote. Now i must admit it was a bit steep and i am considering doing it in stages. (unless some with experience would advise otherwise)

Would it be feasible to buy the motion controller and servo drives first and getting it going while maybe running it off mach3? if Mach 3 is not quite up to it i can always upgrade the software later.

Pieter

-

06-25-2008, 02:24 AM #4

Camsoft/Galil uses analog drives, like your present ones, Mach uses step/direction so you would have a compatibility issue.

If the existing drives are currently fairly reliable, you could conceivably re-use with Camsoft and upgrade later.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

Similar Threads

-

V20 With Anilam Crusader II

By harvard5 in forum BobCad-CamReplies: 5Last Post: 09-24-2011, 01:55 AM -

camsoft retrofit to a anilam crusader retrofit

By bowlingmac in forum CamSoft ProductsReplies: 44Last Post: 07-25-2008, 03:00 AM -

Anilam Crusader II - Crusader 2 Training DVDs

By Mike Mattera in forum News AnnouncementsReplies: 2Last Post: 07-09-2007, 03:31 AM -

Anilam Crusader 2 Help

By porsche1220 in forum CNC (Mill / Lathe) Control Software (NC)Replies: 3Last Post: 04-09-2006, 06:37 PM

Reply With Quote

Reply With Quote