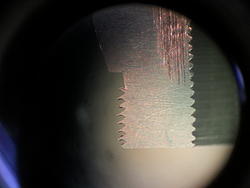

I've been having a problem turning threads on our Haas SL-10 CNC lathe. The thread is a 1.460-40TPI, cutting with an LT16-ER AG60 insert which is rated from 48-8 tpi. Thread depth is .024. The threads are just not coming out right out all. I am turning almost the same tpi in a .995 ID bore which is coming out perfectly. I've attached a photo of the threads in question. You can clearly see these are some cowabunga threads and look like waves. They do not fit in the mating hole well at all. I've tried several different speeds and feeds combo, some having a better or worse finish but almost all turning over the crest of the thread like this. Here is a sample of the code that I'm using

N24 G92 X1.4504 Z-0.2485 F0.025

N26 X1.4408 Z-0.2487 F0.025

N28 X1.4312 Z-0.2489 F0.025

N30 X1.4216 Z-0.249 F0.025

N32 X1.412 Z-0.2492 F0.025

I've tried this at anywhere from 150-5000rpm, constant or reduced x step distance, radial infeed, 2-5 degree flanked infeed.... Nothing is really working. The most frustrating thing is these threads were cutting well earlier this week! Nothing has happened to the machine (crashes,etc) that I know if.

I'd really appreciate any tips!

-Chris

Results 1 to 2 of 2

Threaded View

-

10-11-2014, 01:40 AM #1

Registered

Registered

- Join Date

- Oct 2014

- Posts

- 1

Threading problem Haas SL10 lathe

Similar Threads

-

Haas SL10 Lathe PROBE TAB

By CNCFanMx in forum Haas LathesReplies: 0Last Post: 03-04-2014, 08:20 PM -

Problem with threading on my 7x14 realbull lathe. Please help

By chrisnis in forum Mini LatheReplies: 9Last Post: 05-13-2013, 04:14 AM -

Low RPM Spindle Problem on Haas SL10

By micro-tech in forum Want To Buy...Need help!Replies: 0Last Post: 06-10-2011, 08:56 PM -

Threading problem Victor Lathe 1660B

By rdanner in forum Uncategorised MetalWorking MachinesReplies: 9Last Post: 10-08-2009, 04:21 PM -

Haas SL10 Tailstock problem

By metal surgeon in forum Haas MillsReplies: 4Last Post: 09-04-2006, 05:24 PM

Reply With Quote

Reply With Quote