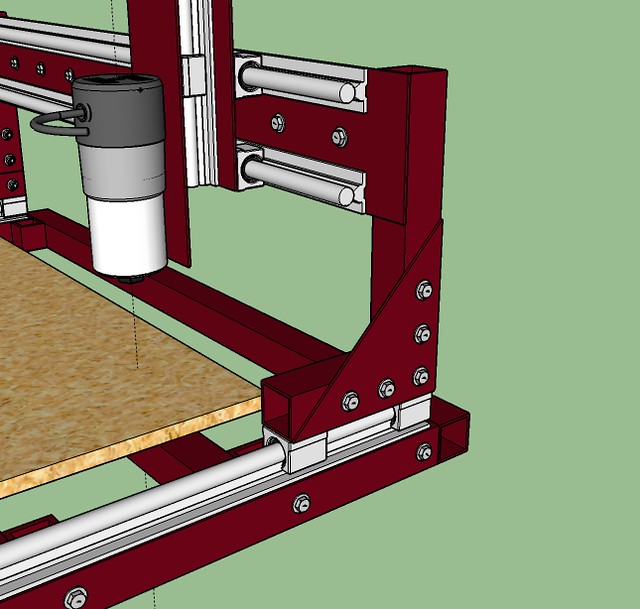

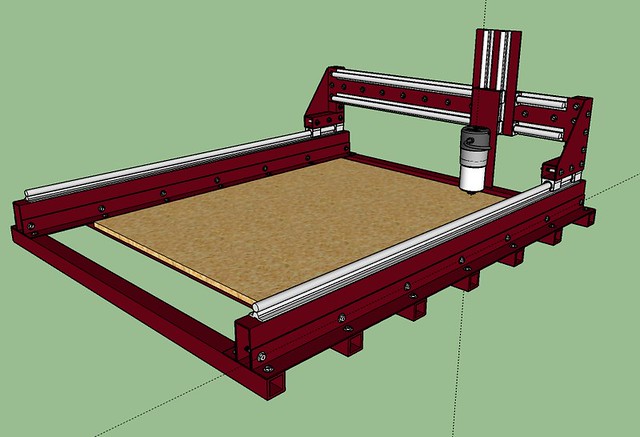

First post! I've been wanting to design and build my own CNC router for a while now and I am thinking it may be a nice winter project for myself. I don't know how to weld and wouldn't want to learn on a project like this anyway. I want it to be a 100% bolt together design to avoid welding but also make it easy to move should I need to. I would be routing mostly sheet goods. As this would reside in my attic, the biggest material that I can fit through the opening would be 36 inches wide so it is designed to handle pieces up to that size. I am thinking 2" square steel tubing for most of the construction with short pieces of tubing in the corners to create the 90 degree angles. The picture should better explain what I am talking about. Please let me know what you think.

Bolt Together CNC Router by jg1996business, on Flickr

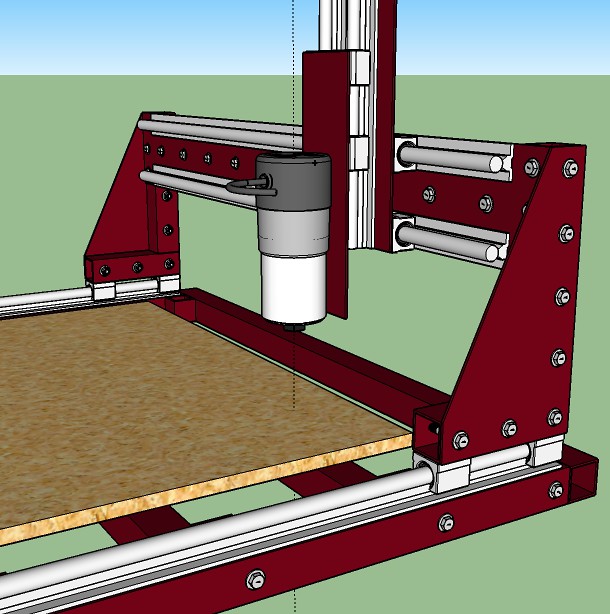

Close Up Gantry by jg1996business, on Flickr

Close up Corner by jg1996business, on Flickr

Results 1 to 20 of 132

-

10-29-2014, 03:01 PM #1

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

Bolt Together CNC Router - Newbie looking for design critique

-

10-29-2014, 03:33 PM #2

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 107

Re: Bolt Together CNC Router - Newbie looking for design critique

Awesome drawings.

I think the steel tubing is strong enough but warps and may not be flat enough surfaces. This leads to binding.

I think the strength of the gantry across the back is weak.

It should be a interesting project. I have seen tables like this successfully built.

Might be time to learn to weld too. It is like spreading molten molasses.

Nice work.

-

10-29-2014, 04:41 PM #3

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Bolt Together CNC Router - Newbie looking for design critique

The small pieces of tubing holding the gantry uprights is a very weak point, and will have a LOT of flex.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

10-29-2014, 04:42 PM #4

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

Re: Bolt Together CNC Router - Newbie looking for design critique

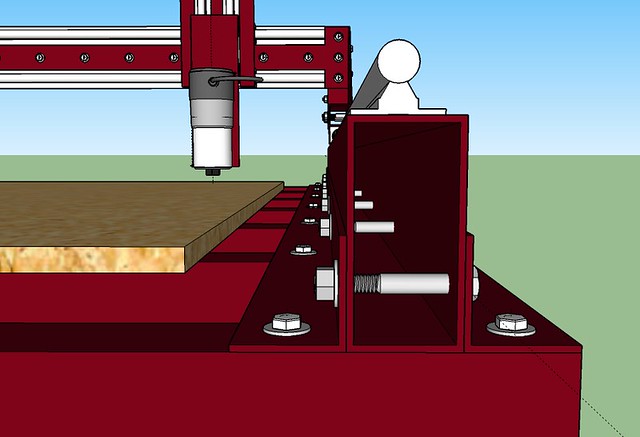

Thanks! The drawings were all done on Sketchup...the free version. Regarding the gantry, I was thinking of bolting a length of the steel tubing along the back to serve as a sort of spine to prevent flexing. Something like this:

Gantry Cross Tube by jg1996business, on Flickr

Gantry Cross Tube by jg1996business, on Flickr

-

10-29-2014, 04:46 PM #5

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

Re: Bolt Together CNC Router - Newbie looking for design critique

I was thinking that as well. Is it a question of the thickness of the steel? I was considering using 2" square 1/4 inch thick tubing for those. Would that help the flex problem? Of course with that thickness I could just tap the hole and screw right into the tubing rather than having to thread a washer and nut on to it.

-

10-29-2014, 05:56 PM #6

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Bolt Together CNC Router - Newbie looking for design critique

It doesn't matter how thick it is, it's going to flex. You need to somehow attach the back side together as well. Otherwise, it's just going to bend forward.

A triangular plate bolted to the side would be a much better option.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

10-29-2014, 08:20 PM #7

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

Re: Bolt Together CNC Router - Newbie looking for design critique

So perhaps something like this?

Triangle Brace by jg1996business, on Flickr

Triangle Brace by jg1996business, on Flickr

-

10-29-2014, 10:11 PM #8

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Bolt Together CNC Router - Newbie looking for design critique

Yes, but even a bit bigger. Like this:

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

10-29-2014, 11:11 PM #9

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

Re: Bolt Together CNC Router - Newbie looking for design critique

You guys rock! So basically like this. It will be harder to fabricate but if that is what it takes.

Triangle Brace by jg1996business, on Flickr

Triangle Brace by jg1996business, on Flickr

-

10-30-2014, 03:50 AM #10

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 122

Re: Bolt Together CNC Router - Newbie looking for design critique

This is a similar design to mine, and where i didnt weld I used bolts to hold it together. Instead of just relying on the wall thickness for the female thread, I used 10-12mm (whatever I had laying around) plate inside the tube with threads tapped in them. So for your gantry risers (vertical tube) you could get a piece of 40 x 10 flat bar and tap 5 threads to suit your bolts. Makes it easer for assy than trying to use standard nuts. This allows you to really tighten them without stripping the thread in the wall of the tube. If you put the bolt right though the tube, it may collapse the tube when tightnening.

Depending on the thickness of the plate across your gantry, I would think a top and bottom tube might assist in rigidity.

-

10-30-2014, 08:38 AM #11

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 25

Re: Bolt Together CNC Router - Newbie looking for design critique

You might also consider raising your rails for a more stable gantry. (Pic of the Kronos machine just to illustrate the principle):

Attachment 255002

Also, I don't know how flat and stable a bolt-together frame will be with those corners, but it reminds me a bit of strut channel construction. You can buy 10" sections of 1 5/8" strut channel locally for < $20 and get fittings from here: ANGULAR Might be worth looking into.

Here's a guy that built a foam cutter out of it: HobbyCNC Foam Cutting Machine

-

10-30-2014, 12:33 PM #12

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

-

10-30-2014, 12:46 PM #13

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

-

10-30-2014, 01:13 PM #14

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Bolt Together CNC Router - Newbie looking for design critique

No, raising the sides allows the gantry sides to be much shorter, or even eliminated. This eliminates, or minimizes a large source of flex. The downside is that it makes accessing the table to load and unload parts more difficult.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

10-30-2014, 02:32 PM #15

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

Re: Bolt Together CNC Router - Newbie looking for design critique

-

10-30-2014, 03:10 PM #16

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 25

Re: Bolt Together CNC Router - Newbie looking for design critique

You want the rails to be rock stable. Instead of the butt-joint with the corner into the 2x6, what about extending the 2" square cross members out a few inches past the sides on each side, then sitting 2x4 rectangular rails vertically on top of the cross members. Then you could run a piece of angle down the outside of each rail and bolt through it.

If I were to do it like this I would probably also run angle down the inside of the rails for more stability--I don't think you'd lose any cutting area because the spindle couldn't travel that far over anyway and your spoilboard will sit above the bolts allowing for the same material capacity.

-

10-31-2014, 04:49 AM #17

Registered

Registered

- Join Date

- May 2011

- Posts

- 72

Re: Bolt Together CNC Router - Newbie looking for design critique

Great advice! Here is the most recent iteration based on your guidance. I changed the cross members to .25 inch thick walls so that I can tap and screw right into them. Let me know what you think please!

Bolt Together CNC Router v2 by jg1996business, on Flickr

Bolt Together CNC Router v2 by jg1996business, on Flickr

End View by jg1996business, on Flickr

End View by jg1996business, on Flickr

Corner View by jg1996business, on Flickr

Corner View by jg1996business, on Flickr

-

10-31-2014, 08:38 AM #18

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 25

Re: Bolt Together CNC Router - Newbie looking for design critique

Looks great! Your SketchUp skills make it easy to see how the details come together. Nice work.

I think that style of frame will work out really well. Here are a few thoughts rattling around my head. Feel free to take them or leave them, or maybe they will just spark some discussion:

- I would probably put the thru bolts pointing out, away from where they can snag the workpiece. Whatever.

- I thought about the issue bolting the cross member last night after I posted the idea, particularly under the inside angle. Going thicker and tapping the holes is a good solution and will make for easy assembly. You could also drill an access hole below and assemble it upside down with a socket extension. But, I still am thinking strut channel (open channel facing up) and spring nuts would work well here. The "Joe's Hybrid" machines use this style cross member. Here's an example: http://www.cnczone.com/forums/joes-c...rid-build.html

- The steel tubing might not make the best rail support. Rectangular steel tubing is hot rolled, meaning it is formed at high temp, and as it cools it warps and the tolerances are poor. If there is slop in the distance between the rails, your gantry will not move freely. If there is slop in Z, the machine is hard to level. So, a lot of people use aluminum extrusion for rail supports and for the gantry crossbeam, which has much better tolerances and keeps everything truer. My way of thinking is that, if you're going to use the steel tubing, why not plan so that you could upgrade the frame later if you want. 80/20 (series 10) 2040 is 2"x4", uses 5/16" T-bolts and nuts and I believe has slots at 1/2", 1 1/2", 2 1/2" and 3 1/2", so if you can drill your horizontal holes into the 2x4 and angle at 1/2" or 1 1/2" for a 5/16" bolt, you leave open the option to just switch it out for the 2040 extrusion later if you wanted.

- The gantry will still need some work, but I think some of that will work itself out as you sketch in the motors and drives. Keep up the great work.

-

10-31-2014, 11:32 PM #19

Registered

Registered

- Join Date

- Jan 2008

- Posts

- 1529

Re: Bolt Together CNC Router - Newbie looking for design critique

Aluminium extrusion is not that flat either, but is probably a bit better than raw RHS.

You should plan on doing self leveling epoxy to make the rail mounting surface.

I'm not sure of the benefit of the angle pieces. A wider tube would be much much stiffer, and you can mount the the bottom of the tube in to the top of the cross tubes. You just tap holes in the long tube and bolt from below.7xCNC.com - CNC info for the minilathe (7x10, 7x12, 7x14, 7x16)

-

11-01-2014, 07:24 AM #20

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 25

Re: Bolt Together CNC Router - Newbie looking for design critique

The intended purpose is to give a wide, stable base to the rails and to give rigidity to the frame with multiple bolts per side that are relatively far apart. You can accomplish the same thing with much larger square tube--it's an interesting idea. Might be a harder to bolt together, but it could be cool.

Similar Threads

-

Critique my 8020 design

By pippin88 in forum DIY CNC Router Table MachinesReplies: 21Last Post: 12-04-2011, 03:07 AM -

Design critique - redbluecnc

By AndyL in forum DIY CNC Router Table MachinesReplies: 1Last Post: 03-10-2011, 02:56 PM -

New build design input and critique

By Worknfool in forum DIY CNC Router Table MachinesReplies: 2Last Post: 09-25-2010, 04:58 PM -

Critique Time.....80/20 design

By mpre55 in forum DIY CNC Router Table MachinesReplies: 22Last Post: 05-24-2008, 10:08 PM -

Evaluate/critique my design

By esm in forum DIY CNC Router Table MachinesReplies: 25Last Post: 04-09-2008, 01:35 AM

Reply With Quote

Reply With Quote