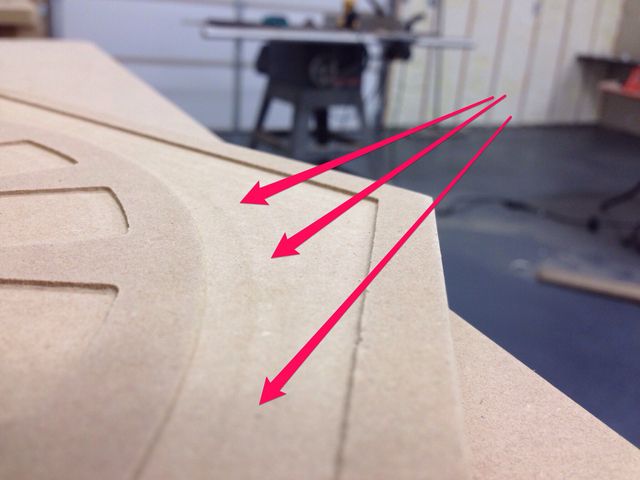

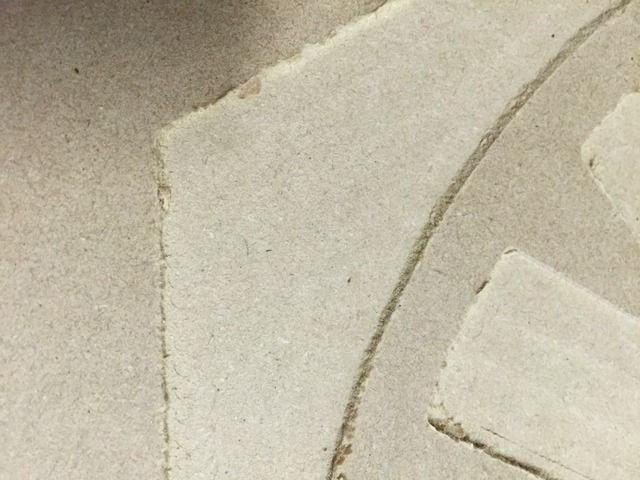

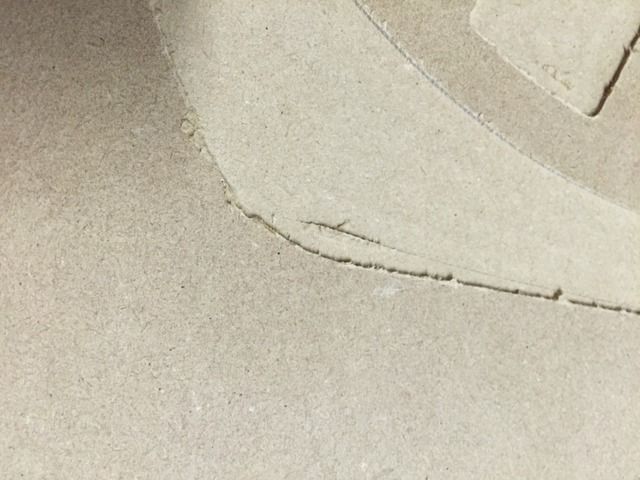

I have discovered an odd occurrence when I was carving today. I am carving a Hexagonal based shape and the corners have different outcomes as seen here. The top picture is correct and the bottom is not. Apologize that I had not sanded first before taking the shots.

The initial job is set to 400ipm at a depth of .0313 and then a second pas at .0625 using an 1/8" end mill. Material is MDF.

I have reviewed the toolpath file in both Aspire and Mach 3 and the anomaly is not there.

I re-ran the file with a single pass at 200ipm at a depth of .07 and the anomaly disappeared. While slowing the job down fixed the issue, shouldn't the machine run at that speed and produce the desired output?

In addition, There is a slight bump in the pocket that is about 1/4" from where the bit stops and goes back as well. This occurred on both runs of the toolpath.

Anybody have some alternate ideas? Is it possible something has worked it's way loose and is causing this? Being able to pick up speed on my jobs was one of the key reasons I upgraded. Like to find a way out of this one.

Thanks,

-Eric

Thread: Carving Anomoly

Results 1 to 19 of 19

-

06-02-2015, 07:37 PM #1

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

Carving Anomoly

-

06-02-2015, 07:46 PM #2

Registered

Registered

- Join Date

- Sep 2010

- Posts

- 717

Re: Carving Anomoly

Maybe try in mach3 settings to go from constant velocity mode to exact stop mode.

And remove G64 (constant vel.) code(s) from your g-code if there is. I'm not sure, but I think the G64 over-rides the mach3 setting.. Current build: http://www.cnczone.com/forums/diy-cnc-router-table-machines/264838-new-machine-desing-quot-cnm13-quot.html

Current build: http://www.cnczone.com/forums/diy-cnc-router-table-machines/264838-new-machine-desing-quot-cnm13-quot.html

-

06-02-2015, 07:57 PM #3

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Carving Anomoly

How fast your machine can go around a corner is dictated by your acceleration settings, as it has to slow down and speed back up to follow the specified path.

When Mach3 is in CV mode, you're telling it to try to maintain a constant velocity. If your acceleration isn't quick enough to follow the path, then it needs to start decelerating earlier, resulting in a rounded corner.

If you want your machine to be as fast as possible, then it needs to be able to accelerate quickly.

Generally, the best option for dealing with this issue is to play with the "Stop CV on Angles >" setting in General Config.You may need to set it as low as 30°. I'd start at 60° and decrease it until you get the results that you're looking for.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-02-2015, 07:59 PM #4

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 88

Re: Carving Anomoly

Hi Eric,

I think you need to change the constant velocity setting in Mach3, because the shape is a Hexagon you might want to adjust the Stop CV on angles >

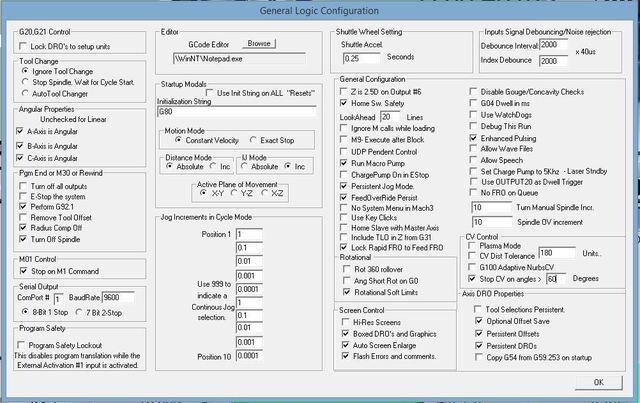

You can find this under Config } General ConfigAttachment 282184

-

06-02-2015, 10:11 PM #5

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

Re: Carving Anomoly

Thanks for the responses. CV was already set. I need to go back and play with the angles. I did try this job twice and while the same issues occurred on both jobs, they did not result in the same anomaly. I will adjust the angles setting and try again. Will that fix the hump that occurs as well?

As I inspected it closer the hump occurs when the bit is going back and forth in small places (about an inch across), it does not occur when going a distance of 6" across.

-Eric

-

06-02-2015, 10:54 PM #6

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Carving Anomoly

What does the hump look like? It sounds like you may be seeing some deflection when plunging?

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-03-2015, 12:13 AM #7

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

Re: Carving Anomoly

It's just a "halo" of the edge of the pocket. It is smooth. No rough edge on it.

I'll snap a pic when I get back out there.

-

06-03-2015, 05:23 AM #8

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

Re: Carving Anomoly

Here is a pic of the "halo" bump I was referring to.

I ran another job this evening and while I dropped the constant velocity down to 60, there is stil some evidence of the first anomaly. I'll keep going down until it's right.

As for the hump, it occurred on this job as well. It shows the same "halo" effect. When I ran the job it appeared that the gantry and the motor for the z axis jitters a little when the x axis changes direction. I could not find anything loose On the system.

It could very well be deflection. There is no rough edge and from what I can tell, it looks like the motor makes it too top heavy and causes the mount to flex. I am sure I need to tighten something. I hate to think that 1/32" deep at 400ipm is enough to cause this.

-Eric

-

06-03-2015, 05:37 AM #9

Member

Member

- Join Date

- Jan 2007

- Posts

- 1795

Re: Carving Anomoly

you can set ""stop cv at angles"" to 120 what actually the hexagon corner..

the corner cv distance set to 180 you can turn it on and set a lower number.. but a lower number combined with higher accel, might causing jerk motion..

so it need some test to find the right settings for your machine..

between passes the line occur in any machine.. it is because of the rotary tool..

as passes are next each other, the fibers are ""bending""

as tool spin on left side it going forward, right side backward... so it makes a visible difference.. what is not a measurable difference..

-

06-03-2015, 12:55 PM #10

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Carving Anomoly

It doesn't work that way. It needs to be set to 180-120 = 60, but should be a little less to be safe.you can set ""stop cv at angles"" to 120 what actually the hexagon corner..

Personally, I'd make sure that all other CV options are turned off.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-03-2015, 05:34 PM #11

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

-

06-03-2015, 06:43 PM #12

Member

Member

- Join Date

- Jan 2007

- Posts

- 1795

Re: Carving Anomoly

thank you Gerry.. I really didn't know that..

the other cv settings, I think he has to make his own experiment to see and learn how it works.. turning on one and making tests..

otherwise he going to be confused with any advice..

-

06-04-2015, 01:05 AM #13

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

Re: Carving Anomoly

I ran another job today and it looks the first anomaly has gone away. However, the "hump" is still there. I ran two passes on it. One at 400ipm and the other at 200ipm. I ran it a third time at 100ipm and it disappeared.

What I observed is that the top of the Z axis has a jitter to it when the y motor changes direction. The centripetal force of the stop and start causes the bit to lift. I checked all my mount points and all is tight.

Is it possible to decelerate as it approaches a stop and then speed back up?

Thanks,

-Eric

-

06-04-2015, 04:06 AM #14

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Carving Anomoly

I can't really see the "hump" in the pics, so I don't really know what it is.

It always does. Physics won't allow it to be done differently.Is it possible to decelerate as it approaches a stop and then speed back up?

One issue with Mach3, especially at higher speeds, is that the trapezoidal acceleration curve can get rather violent, and if there's any flex in the machine at all, you'll see it.

I think on the Settings page, you'll see a CV feedrate. I think it's on by default. I'd turn it off.Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-04-2015, 04:56 AM #15

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

Re: Carving Anomoly

I'll check the settings page and try again tomorrow.

The pic that illustrates the "hump" is on post #8. The one with the arrows.

If you follow the curve in the pic, it is about a 1/4" away from the curve right where the arrows are pointing too.

I cal it a "hump" there may be another term for it. It essentially a smooth rise and fall about a 1/4" from the edges of a pocket. The hump is bigger the faster I go and it disappears around 100ipm.

-Eric

-

06-04-2015, 01:04 PM #16

Company Representative

Company Representative

- Join Date

- Feb 2004

- Posts

- 1086

Re: Carving Anomoly

It is possible to tighten the v-bearings on the z axis by rotating the eccentric bushings underneath the v-bearings on one side of the axis. If the issue is in fact deflection, this is where I would suspect it would occur. If you'd like to discuss feel free to call us and Cory or I can look into this with you.

Best regards,

Ahren

CNCRouterParts

-

06-04-2015, 01:31 PM #17

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Re: Carving Anomoly

I see the pic, but I can't really make out the hump.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

06-04-2015, 02:14 PM #18

Member

Member

- Join Date

- Jan 2007

- Posts

- 1795

Re: Carving Anomoly

if the 100 ipm eliminate it, and it is important to looking nice, then use the 100 ipm...

saving 19.5 second and sanding 15 min is not an advantage really..

let machine working a min longer and save a lot on sanding..

I know its very impressive when machine runs with 300 ipm.. but you have to take into account routers are not machining centers..

a good vmc can run even 2000 ipm and making smooth surfaces..

routers, no matter what made they always behind machining centers..

-

06-15-2015, 04:55 PM #19

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 73

Re: Carving Anomoly

My schedule got really busy and was finally able to get back to this. I shot a video of the motor on top of the Z axis. When it stops and changes direction you can see the motor stutter a bit. That stutter translates into the "hump" on the workpiece.

https://youtu.be/WUxHRIiOlro

Similar Threads

-

Surfacing Anomoly

By RHT in forum Uncategorised WoodWorking MachinesReplies: 1Last Post: 04-09-2015, 03:43 PM -

Best bit for v carving

By William McLean in forum WoodWorking TopicsReplies: 6Last Post: 03-01-2011, 09:05 AM -

V23 3D carving

By csmoak25 in forum BobCad-CamReplies: 9Last Post: 04-14-2010, 04:00 AM -

CNC for Ice carving!

By asandoval in forum Community Club HouseReplies: 1Last Post: 03-20-2009, 06:59 PM -

Relief carving small detailed parts - V-carving from greyscale image

By ALAN2525 in forum Uncategorised CAM DiscussionReplies: 16Last Post: 02-12-2007, 12:01 AM

Reply With Quote

Reply With Quote