Gentelmen,

I am currently deciding what Tool Room mill would be the best value. I am comparing the Sharp SV-2412 to the Haas TM-1. I have plenty of exposure to the Haas machines and there controller, but the Sharp seems to be a more rigid Machine Tool. My worries are the service and reliabilty of the Sharp Machine. Could anyone please give me your experiences and feedback on the machine and controller for the Sharp? It would be of great help in making this decision. Thanks in advance.

Thread: Sharp SV-2412

Results 1 to 19 of 19

-

12-14-2006, 02:26 PM #1

Registered

Registered

- Join Date

- Dec 2006

- Posts

- 6

Sharp SV-2412

-

03-24-2007, 12:42 AM #2

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 18

Hass Vs. Sharp

Hass Vs. Sharp

If you want a straight up comparison call bob at performancemachinetools.com, 27 years in the machine tool biz.

later

John

-

09-04-2007, 06:08 PM #3

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 97

I am making the same comparison for a purchase I want to make before year's end. If you learn anything significant please post. I'll do the same. So far I have had a bit of trouble getting good info on the Sharp other than the fact that my local Haas dealer trashes them on both quality and service. But others tell me that here in the Pacific Northwest the Haas service is absolutely terrible. I will say that their (Selway's) sales response has been poor so that does make me wonder if I can't get a call back when I want to buy how much luck will I have when I need service after the sale.

-

09-05-2007, 10:05 PM #4

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 174

I have a Haas TM-2 and if I had to buy a new machine I would definitly look at the Sharp. My Haas is so slow, and it gets coolant all over the place. I can cut most materails, just have to be careful not to push it to hard. The Mazak dealer in my area also sell's Sharp. He has sold quite a few of the SV-2412's and he said they have been rock solid little machines. Fast smooth running machines, I use Mastercam X2 so I don't programming at the machine. If you don't have a cam program I would look at the Hurco VM-1, they have one of the best conversational controls in the industry.

-

09-06-2007, 10:14 PM #5

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 97

thanks

Thx for the info. I checked out the Hurco VM1 at the local dealer and it does look really nice but it is just too expensive for my needs. I'm going to go check out the Sharp next week.

-

09-07-2007, 11:37 AM #6

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 232

I Have a sharp 2412 its 2 years old and i have had no problems with it Very ridged machine .I looked at the hass mini mill and they wanted to charge me for every little option it just got silly they even wanted $400 for a plexiglass top.The hass came to about $40k with just basic options.I never could find out the true horsepower.Also the hass has very litte z travel

but a kurt vise under it and a jobbers lenth drill in it and you only have a few inchs of room under the vise.

You can get more z height but again thats an option.

I then looked at the sharp I thought a tiawain machine would be junk but I found they have come a long way.It comes with a fanuc control ridged tapping a coolant pump that puts out more than a garden hose and the machine even has a top.It has box ways 18 inchs of z and weights about 2000 lbs more than the hass. I paid $ 35k for the sharp .To me the desision was a no brainer.

Tim

Tim

-

09-07-2007, 12:48 PM #7

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 174

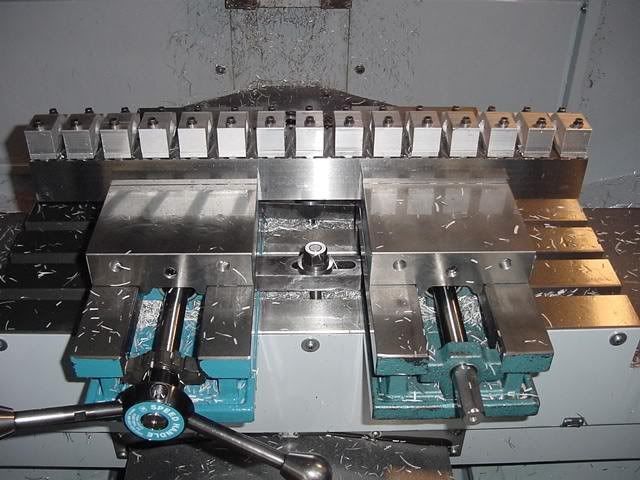

Man that's a nice looking little machine. What do you use to program it? I wish I could have gotten one of those insted of the Haas TM-2. My TM has 16" in y, and I have only needed that once.

-

09-09-2007, 12:08 AM #8

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 13

Hi Timlkallam,

Nice pics of the Sharp in action! I nominate you for best action sequence of VMC stills seen today!

I was also getting serious about a Haas TM-1P, one of your pics (#5) is good evidence why you need the "P" for the Haas toolroom mills. I am now pretty intrigued about the Sharp--I notice that they spec 0.0002" accuracy/0.0001" repeatability, about twice as good as the Haas toolroom mills. Have you checked whether they can really meet those accuracy specs?

I am purchasing this machine for a job which requires machining a 7075 clevis part on each end of a tube, with up to 42-43" between opposite clevis eye centers, with about 0.002" tolerance on the eye-to-eye distance. We were planning to manually end-for-end the part after the first eye was milled, using an indexed tool that would allow the other end of the tube-clevis assembly to extend off the end of the table a bit, within the confines of the machine covers. With the 30" x-travel of the TM-1P, this appears reasonable. Any sense of whether you could do this operation with the 24" travel of the Sharp?

-

09-09-2007, 07:49 AM #9

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 232

I question the accuracy the sharp states, its a boxway machine so there has to be some clearance in the ways.

I can put an indicater on my spindle and and push hard and move the head +-.0004 I don't know if this is normal or not .I could tighten up the gibs but if i tighten to much i could damage the ways. I can say it will repeat within .0002 cutting small alum. parts. I put an .0001 B&S indcator in the spindle to adjust the backlash after i was finished I wrote a program to move the table back and forth to see if the table would stop at the same place every time and it would repeat well under .0001 but cutting under a load my yeild different results. Position .0002 accuracy over the full travel I don't know. If you are looking mainly for accuracy .I think the hass would be more acurate because it has linear ways no clearance, no stick slip . As for the .002 tolarance for your part no problem, the sharp has hinged doors on the sides of the machine so your part can stick out. Whats a clevis do you have a picture?

TimTim

-

09-09-2007, 11:22 PM #10

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 13

Thanks for those tests, the repeatability at least sounds like it may be possible. Don't need such accuracy now, but its nice to know it may be possible. I am glod to hear those side doors allow parts to stick out--that helps a lot.

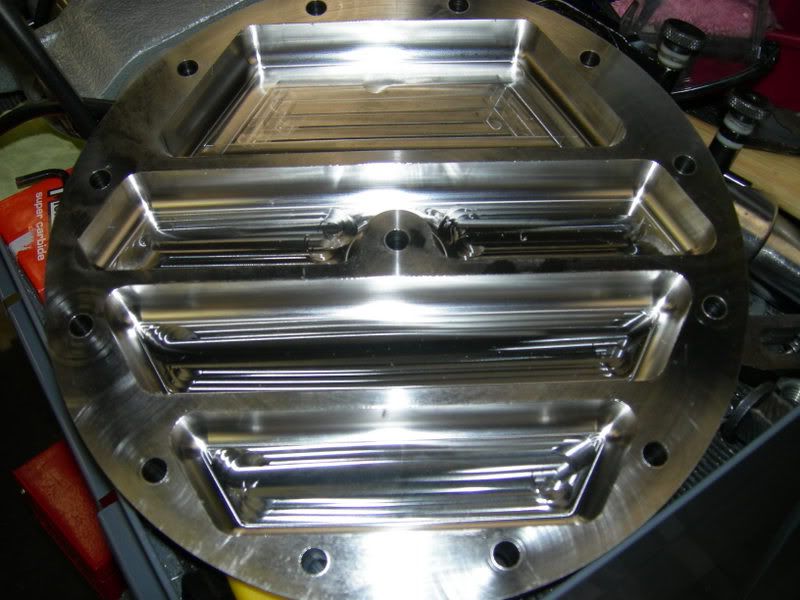

Here are some shots of some of the tongue and clevis joints we will be making (about 200 or so eventually) for our reflight of a NASA balloon payload next year, that is one of our near term tasks at hand for a VMC in our physics shop. We flew the payload (last pic--a set of radio horn antennas on a 25' high truss structure) early this year in Antarctica, but it got dragged a half-mile across the ice after it landed and every single part got damaged or tweaked. The whole truss structure has to be held to few-thousands tolerance on the individual tube+clevises, otherwise the errors build and it won't go together. The 7075 clevis parts are joined to thinwall 6061 tubing via a pulse-weld techniques (its something like a high-pressure cold swage joint--not a hotweld).

-

09-10-2007, 07:40 AM #11

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 232

Ok i understand now .I would love to work on a project like that.

Tim

-

09-10-2007, 11:05 PM #12

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 13

Tim,

Seriously, we are hiring a staff machinist/instrument builder over the next few months. The job is not properly posted yet but if you are interested there is a craigslist hawaii preliminary post on it. The project above is one of the first tasks for that position....

-

09-10-2007, 11:10 PM #13

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 13

Tim,

Seriously we are hiring a staff machinist/instrument builder over the next few months, the job is not posted in the university system yet, but see the preliminary post at craigslist hawaii if you are interested. The project above is the first one in the queue when the new guy starts....

-

09-11-2007, 03:11 AM #14

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 13

Got my quote for the Sharp, seems very reasonable, with good base features as noted by Tim above. I am trying to figure out the 4th axis option, it seems that you have to opt for the Fanuc Oi-MC control (a $6200 upgrade) to get a proper 4th, along with another fairly pricey interface option: "Internal wiring; amplifier for Fanuc Alpha C3 Servo Motor (Motor and cables not included) $4850". So if I have this right, its another $11K over the base price *before* you have bought the servo rotary table.

Has anybody else ever got this all sorted out for the Sharp 2412? I wonder why the Fanuc control with 4th axis capability is such a big bump--is this just pricing strategy?

-

09-11-2007, 06:38 PM #15

Registered

Registered

- Join Date

- Sep 2007

- Posts

- 1

-

09-15-2007, 02:03 AM #16

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 32

I have had my 2412 for a couple months now an think it is great. I am ready to try to hook it up to my network but don't no how to set up the perimeters and the manuals are Greek to me. Does anyone have any experience in this area? I do want to use the network hookup not the rs232.

-

09-15-2007, 09:08 PM #17

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 5

That is an awesome project. Is that the one built in Baton Rouge at the Physics and Astronomy department of LSU? If not, they did one like it.

Keith

-

10-12-2007, 02:11 PM #18

Registered

Registered

- Join Date

- Aug 2005

- Posts

- 578

I also have a 2412S. mine is with a fourth. 0iMc control and a Tsudakoma fourth.

If you get a fourth with it, pay attention to the motor requirements as you can overload the machines powersupply. Mine were purchased seperately so I can't blame anyone but myself but Sharp is talking to me about fixing it for me anyway. I've had mine for about a year and am solidly impressed with this machine. Zero issues. It's spent the majority of it's time here machining 316ss heat exchangers. Nasty stuff

-

10-12-2007, 02:58 PM #19

Registered

Registered

- Join Date

- Apr 2007

- Posts

- 32

looks like a nice piece of work there!

Reply With Quote

Reply With Quote